How to Choose Temperature Indicator Labels for Packaging

A temperature indicator label’s primary function is to identify, tag, categorise, and provide information about a product’s exposure during storage or shipment. This article will share more information about packaging to protect goods against temperature damage.

What is a temperature indicator label?

A temperature indicator label is a small, easy-to-use, cost-effective control device. It determines and displays a product’s duration of exposure to excessive temperatures during shipping, storage or processing. Typical applications include monitoring the temperature of pharmaceuticals, chemicals, and fresh produce during transportation.

The packaging labels change colour if a temperature excursion is outside the preset limits. There are a variety of temperature indicator labels. Labels like the Time-Temperature Indicator indicate if the temperature deviation exceeds a preset time. The Freeze Check and ColdMark temperature indicator are used in shipments to indicate a temperature deviation below 0°C.

Temperature indicator labels have temperature-sensitive elements that produce unique, high-precision colour change effects using the sharply defined melting points of a series of specially purified organic chemicals. Each temperature point uses a different chemical compound and is made separately by applying a chemical coating to a unique paper substrate.

When the temperature exceeds, the chemical melts and is absorbed by the substrate, resulting in a permanent colour change. They can be attached to almost any surface with their solid adhesive backing. This makes the packaging labels ideal for temperature monitoring as users can apply the indicator to the surface and monitor it later to determine the highest temperature.

Benefits and Advantages

Temperature is a packaging solution to help determine perishable products’ shelf life. Deviations in the temperature profile can result in the growth or survival of microorganisms, which ultimately causes product spoilage. Furthermore, incorrect freezing can denature the proteins of meat or other products. Temperature indicator labels can be used to monitor if the cold chain or a required temperature is effectively maintained during the food supply chain.

There are various advantages to using temperature indicator labels over other methods of determining surface temperature. First and foremost, the temperature readings obtained are undeniably from the measured surface. Since the temperature-sensitive indicator label is directly applied to the surface, it changes state in direct response to only that surface.

Another advantage of employing temperature indicator labels is that users do not have to worry about signal delays. Since a mark made by a crayon has such a small mass, it quickly reaches equilibrium with the surface. Using a huge probe increases response time and may result in an inaccurately low value. There is no heat transfer away from the surface when using temperature indicator labels and no reliance on the duration of heating.

The third advantage of indicator labels is that their application is straightforward and affordable. Most alternative methods of determining surface temperatures necessitate technical skills, knowledge, and sophisticated instrumentation. Indicator labels provide surface temperature measurements with minimum effort, training, or cost.

Applications and Usage

Medical solutions: Temperature indicator labels are used in the medical field to maintain the integrity of medical devices, pharmaceuticals, vaccines, blood, organs, and tissue, among other things. All of these require different temperature ranges.

Food Temperature Monitoring: Proper temperature monitoring can distinguish between profit and loss, edible and ruined, and safe and hazardous. Hence, choosing the best cold chain monitoring selection for unique needs is crucial whether transporting Frozen, Refrigerated, Packaged Goods, Dairy, or Seafood.

Industrial Solutions: Industrial temperature monitoring is helpful for manufacturing processes, heat treating, electronics, aerospace applications, shipping and storage, automotive, sterilisation, bonding textiles and much more. Using an indicator label also maximises safe product handling, as staff will follow relevant rules when handling products.

Types of Temperature indicator labels

Temperature indicator labels are vital tools that show if a product has experienced undesired temperature ranges. Different labels cater to diverse needs, from cold chain logistics to food freshness during transit. This section will explore the various temperature indicator labels available.

Non-Reversible vs Reversible Labels

Reversible temperature labels can change back and forth to indicate the temperature readings. One advantage of reversible labels is that they can be used repeatedly. Non-reversible temperature labels are usable once to indicate the preset temperature has been reached. Non-reversible labels are useful when an operator is unavailable or cannot access the label attached to the product tested. A non-reversible label can be evaluated anytime to see if the specified temperature has been reached.

Three to five-level temperature labels

These temperature indicator labels provide a precise, affordable, disposable record of temperature changes. The irreversible temperature indicators are available in one, three, five, or eight temperature steps, ranging from 32°C to 260°C.

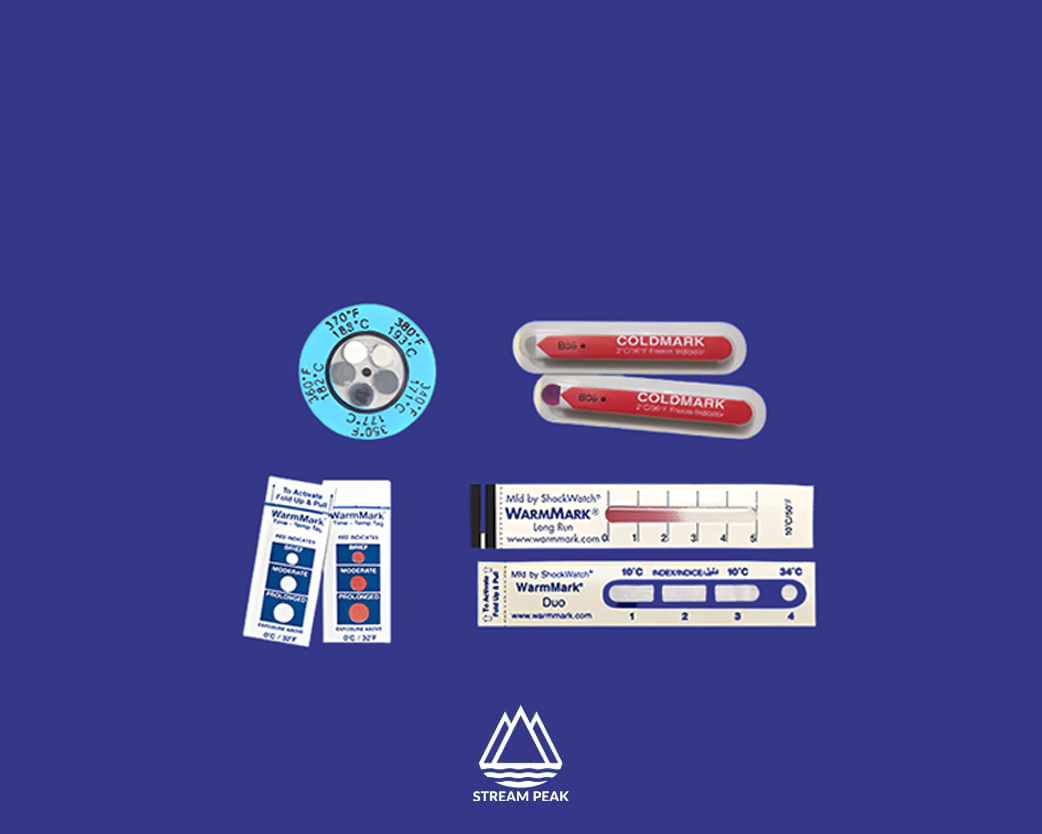

These temperature indicator labels can be utilised in the following applications: manufacturing, processing, storage, shipping, monitoring the shelf temperature of heat-sensitive products, dishwashers, heat sanitising, ovens, dryers, and curing operations. One example is the Thermax five-level temperature clock indicator.

They are simple temperature-monitoring packaging solutions with five-alarm stickers that change from silver to black individually as the temperature rises above specific values. Each alarm sticker is triggered at a different temperature level to provide better data on the temperature during shipping.

Time-Temperature Indicators

Time-Temperature Indicators have a variety of time and temperature ranges. They can monitor the cold chain for perishable products, vaccines and a wide range of other applications during shipping and storage.

WarmMark: This single-use time-temperature indicator alerts users when their products are exposed to unacceptable temperatures. This single-use temperature recorder for shipping turns red when it reaches the temperature threshold selected.

Then, unlike many temperature indicator labels, WarmMark starts a countdown, with its three indicator dots changing colour for brief, moderate, and prolonged exposure. Those durations vary by temperature. WarmMark provides insights into cold chain logistics so the user will know which packages may have experienced thermal damage and which were handled correctly.

WarmMark Duo: This temperature indicator indicates the duration of temperature exposure at two different activation temperature levels, 10°C and 34°C, in one packaging indicator.

If the temperature climbs beyond two specific thresholds, a red colour moves through the windows of the indicator with time. If the temperature returns below the threshold, the red colour stops moving. This way, handlers and shippers could know how long the product was exposed above the threshold temperature.

WarmMark Long Run: This temperature indicator indicate a product’s long-term exposure to temperature excursions above ten °C or 31°C. The WarmMark Long Run, packaging temperature indicators, will monitor for long-term vulnerabilities for up to 7 days, depending on the severity of the temperatures experienced.

Also, it is helpful for products with known temperature stability and expiration characteristics at a specific time or temperature combination. The WarmMark Long Run can positively affect the business bottom line by indicating a product’s long-term exposure to temperature excursions.

Freeze Check Temperature Indicators: They detect temperatures that are below 0°C. Once it reaches an out-of-range temperature, the irreversible temperature indicator turns white, and the check mark disappears.

ColdMark Temperature Indicators: They are available at 0°C and -3°C and apply to a product, package or carton of products sensitive to extremely cold temperatures.

Blood Temp 10: This accurately monitors the temperature of blood bags during storage and transit. If the temperature breaches ten °C, the temperature indicator will visually alert handlers.

Key considerations when choosing the correct label

As there are a wide variety of temperature indicator labels in the market, choosing the correct one is especially important to measure product temperatures accurately.

Temperature range: Monitoring the temperature is critical in choosing the best label. First and foremost, the target temperature must be included to examine the history of temperature transitions over the threshold temperature.

Outdoor/Indoor use: Organising the products in the product portfolio matrix divides the products by two factors: the location of use (indoors/outdoors) and reusability. Choose the more durable labels if products are exposed to sunlight, water, oil, sand, and other elements.

Reversible/Irreversible: Reusability is the other factor in sorting the product portfolio matrix. Reversible labels are primarily used indoors to check cable and pipeline temperatures. In contrast, irreversible labels are used outdoors, such as for the safety control of outdoor electrical devices, lines, panels, and other components in power plants.

Conclusion

By understanding the specific needs of the product and the conditions it will face during transit, businesses can make informed decisions prioritising safety and quality. As the market continues to evolve, staying informed about the latest advancements in temperature-sensitive solutions will be instrumental in ensuring the utmost protection of goods.

Stream Peak supplies a comprehensive range of temperature indicator labels tailored to various packaging needs. Contact us and make an appointment with our packaging engineers for insights, guidance, and recommendations to ensure you choose the right label for specific requirements.