Protect Goods Against Damage with Shock Watch Labels

Ensuring their safe arrival is paramount when shipping and transporting delicate or fragile goods. The jostling, vibration, and impact during transit can potentially lead to significant damage. Shock Watch Labels protect goods against mishandling and minimise the risk of damage. These packaging labels deter mishandling and provide proof of rough handling, ensuring accountability throughout the supply chain.

Protecting Goods Against Damage

Fragile goods require extra care during packaging due to their susceptibility to damage from external forces. Here are some reasons why fragile goods need special attention during the packaging process:

- Vulnerable Material: Fragile goods are often made of delicate or brittle materials that are more prone to impact damage. Materials such as glass, ceramics, fine china, or sensitive electronic components can easily crack, shatter, or become unusable when subjected to sudden or excessive forces. Extra care must be taken to safeguard these materials during packaging.

- Lack of Inherent Protection: Unlike more durable or robust items, fragile goods often lack built-in protection mechanisms. They cannot withstand impacts or absorb shocks on their own. Therefore, proper packaging techniques and materials are essential to provide the necessary cushioning and support to mitigate the risk of damage.

- Unpredictable Handling: During transportation and handling, packages can experience various impacts, including drops, collisions, or rough handling. Fragile goods are particularly vulnerable to these impacts due to their delicate nature. Extra care in packaging helps create a protective barrier that absorbs shocks, reduces the transfer of impact forces, and minimises the risk of damage caused by mishandling.

- Environmental Factors: In transit, packages may be exposed to environmental factors such as vibrations, temperature changes, or humidity fluctuations. These factors can amplify the impact forces experienced by fragile goods. Proper packaging helps create a buffer zone that protects the goods from the combined effects of environmental conditions and impacts, reducing the likelihood of damage.

- Stacking and Compression: Fragile goods are often part of a larger shipment and may be stacked or subjected to compression forces during storage or transit. Excessive pressure from stacking or compression can lead to deformation, breakage, or collapse of fragile items. Appropriate packaging techniques, such as using sturdy boxes, adding protective layers, or incorporating reinforcements, help distribute the forces and ensure the integrity of the goods.

- Transport Hazards: During transportation, packages may encounter various hazards, such as uneven road surfaces, turbulence during air transport, or sudden stops. Fragile goods are highly susceptible to damage from these hazards without proper packaging. By implementing protective measures, such as secure packaging, internal padding, and shock-absorbing materials, the impact forces can be effectively mitigated, reducing the risk of damage.

By employing appropriate packaging techniques, materials, and protective measures, businesses can significantly enhance the safety of fragile goods during transit and ensure their intact arrival at the intended destination.

The Role of Shock Watch Labels

Shock Watch Labels are impact packaging indicators that monitor the conditions to which a package or product is exposed during transit. They are designed to detect and record excessive impact or mishandling, providing a visible and tamper-evident warning to carriers and handlers. The labels are strategically placed on the packaging and respond to specific thresholds of impact forces, typically measured in G-force.

- Visual Deterrence and Accountability: The primary function of Shock Watch Labels is to act as a deterrent against rough handling. The visible presence of these labels serves as a visual reminder to handlers that the package is being monitored. Knowing that their actions are being monitored increases the accountability of carriers and handlers, prompting them to exercise greater caution and care.

- Evidential Proof of Mishandling: Shock Watch Labels provide tangible evidence of mishandling and their deterrent effect. These impact labels are equipped with a mechanism that irreversibly changes colour or displays a clear indicator when an excessive impact or mishandling event occurs. This visible evidence helps determine responsibility and allows businesses to act appropriately in damage claims.

- Supply Chain Optimisation: By implementing Shock Watch Labels, businesses can proactively address mishandling concerns and optimise their supply chain. The impact labels allow companies to identify potential packaging, handling processes, or carrier selection weaknesses. By gathering data from Shock Watch Labels, businesses can make informed decisions to improve their packaging design, optimise logistics, and select reliable partners to reduce the risk of damage during transit.

- Enhancing Customer Satisfaction: Damage to goods during transit leads to financial losses for businesses and negatively impacts customer satisfaction. Implementing Shock Watch Labels sends a strong message to customers that their goods are handled with utmost care. This proactive approach reinforces trust and enhances the overall customer experience by ensuring that products arrive pristine.

- Industry Applications: The applications of Shock Watch Labels are diverse and widespread. Industries such as electronics, medical devices, automotive parts, glassware, artwork, and delicate equipment benefit significantly from this technology. Regardless of the industry, any business concerned about the safe delivery of their products can integrate Shock Watch Labels into their packaging and logistics processes.

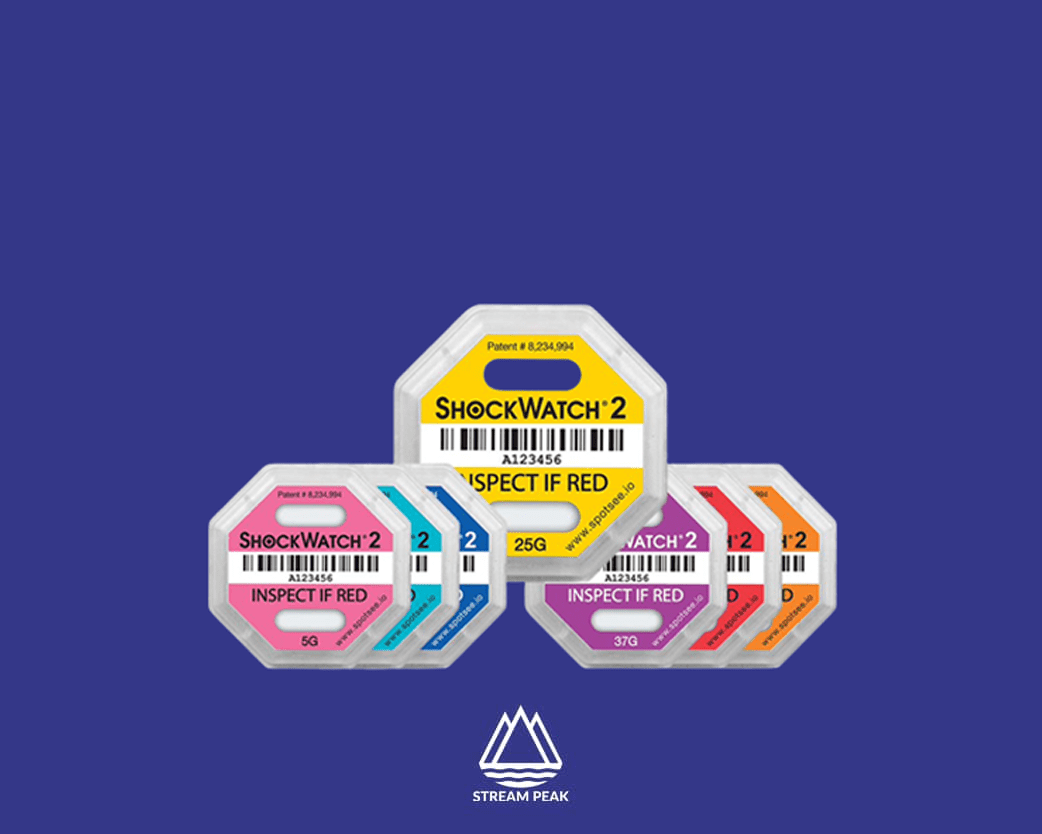

Types of Shipping Impact Labels

When protecting goods during transit, shipping impact labels provide visibility and accountability for potential mishandling or rough treatment.

- Tip-N-Tell Indicator: The Tip-N-Tell Indicator is a highly effective shipping impact label that provides clear evidence of mishandling. It is a tamper-proof, self-adhesive label that contains a vial with an encapsulated dye. When exposed to excessive tipping or tilting, the vial breaks, releasing the dye and irreversibly staining the indicator window. This visible indication indicates that the package was mishandled or tipped during transit.

- TiltWatch Indicator: The TiltWatch Indicator is designed to detect and indicate when a package has been tilted beyond a specified angle. It consists of a self-adhesive label with a glass vial containing a red liquid. The vial is precisely calibrated and breaks when the package is tilted beyond the specified angle, causing the liquid to flow into the viewing window. This clear indication alerts handlers that the package is tilted and prompts them to handle it carefully.

- ShockWatch Label: ShockWatch Labels are impact indicators that provide evidence of excessive impact or mishandling during transit. These labels consist of a self-adhesive label with a glass tube containing a red liquid and a visual window. When subjected to a force beyond the predetermined threshold, the glass tube breaks and the liquid fills the visual window. The unmistakable change in colour indicates that the package experienced a significant impact, ensuring accountability and prompting careful handling.

- Drop-N-Tell Indicator: The Drop-N-Tell Indicator is designed to monitor vertical impacts during transportation. It is a self-adhesive label with a drop indicator mechanism that contains a vial with an encapsulated dye. When exposed to a significant vertical impact, the vial breaks, releasing the dye and producing a red mark on the label. The visible mark proves that the package was dropped or subjected to a substantial downward force, emphasising the need for careful handling.

- ImpactLabel Indicator: The ImpactLabel Indicator is a versatile shipping impact label that detects and records excessive impacts. It features a self-adhesive label with a shock-sensing device that reacts to impacts in any direction. The label contains a digital counter that increases each time an impact occurs. The counter is visible through a small window, indicating the number of impacts the package has experienced.

These are a few examples of shipping impact labels. Each type of label serves a specific purpose and helps businesses identify potential mishandling or impacts during transit. By using these shipping impact indicators, companies can enhance accountability, encourage proper handling, and take necessary measures to ensure the safe transportation of their goods.

Conclusion

In an increasingly interconnected global marketplace, the safe and secure transportation of goods is a critical concern for businesses across industries. Shipping impact labels provide a powerful solution to protect goods against damage during transit by deterring mishandling, providing clear evidence of mishandling events, optimising supply chain processes, and enhancing customer satisfaction. By embracing these intelligent labels, businesses can safeguard their reputation, reduce financial losses, and ensure that products reach their destination in good condition.