Things to take note before buying a packaging machine

Purchasing a packaging machine can allow a business to increase production operations with cost savings in the long run. With the correct specifications, the machines can increase the efficiency of the overall production line and reduce lead time. However, packaging machines is a huge investment that requires careful decision-making. This article will explore the critical factors to consider before purchasing a packaging machinery.

Understanding the Packaging Requirements

What are the pain points that are needed to be solved with new machinery? Here are some questions to ask before narrowing down a selection:

Dependability: Does the packaging machine be required to operate 24/7? Or a semi-automatic bagging machine with one operator to manage the flow? Although many modern machines can multi-task, a business model can change in the long run to meet market opportunities. Don’t decide on the latest all-in-one machine because of its specifications, but talk to different suppliers to gauge what works for the business.

Speed: Speed rates are measured by how many bags per minute (bpm). Does the production line need three times the speed to meet the demand? Plan with forecasted sales for the next five years to determine the purchase requirements to support the targets. For example, a vertical form fill seal packaging machine can pack 100 bags of food or non-food products per minute. A point to note is that the quicker the output and quality of the machine, the more investment is required.

Product Specifications

What are the dimensions of the item? Are the products powder, liquid, or solid? The right packaging machinery should first meet the requirements of the products. In addition, consider what packaging materials will be used with the machines. An example of the packing of granular items such as coffee beans or pet food is purchasing a linear compact premade pouch machine instead of a liquid-and-paste packaging machine.

For products packed in different styles, opt for a flexible packaging machine that allows configuration to meet different bag requirements. For preventive damage, use secondary packaging to hold products together, such as paperboard cartons and air pillow packaging. We will share more on the different types of bags below:

Pillow bags: Also known as centre seal pouches, they are the most common packaging method due to their economical and flexible form, and it is easily customisable. It is commonly used in food industries.

Sachets: Also known as 4-side seal pouches, they are an economical leak-proof product that is slim and compact. They are often used for liquid and powder items such as coffee and snacks.

Gusset bags: A gusset is similar to a pillow bag but with more capacity. Bottom gusset pouches are more popular as they can stand upright on a shelf. They are also oxygen and moisture-resistant.

Key Features to Look Out For

When investing in a packaging machine, it’s crucial to evaluate its features thoroughly to ensure it meets specific operational requirements and offers long-term reliability. A machine’s features can significantly influence its performance, efficiency, and the overall quality of the packaging process.

Automation Levels

Understanding the automation levels is crucial when considering the right packaging machine for operations. Speed and efficiency can significantly affect production output and operational costs. Check the machine’s maximum packaging speed, often measured in packages per minute or hour.

Ensure that it aligns with production needs. A machine’s uptime (the time it operates without interruptions) is a vital metric. Higher uptime means less downtime for maintenance or malfunctions. Do also check the efficiency rate, which refers to the percentage of products packaged correctly without errors or waste.

Semi-automatic Machines: Often less expensive upfront but may require more labour over time, these require manual intervention for certain aspects of the packaging process. For instance, a worker might need to place items into the package while the machine seals it. They are suitable for businesses with lower production volumes or those that need flexibility for short runs or special products.

Fully Automatic Machines: Designed to handle the entire packaging process without manual intervention, from feeding the product to sealing and labelling. It is ideal for high-volume production lines where consistency and speed are essential. Typically, they involve a higher initial investment but can lead to labour and cost savings in the long run.

Installation and Space Requirements

How much floor space can the production area accommodate for new packaging equipment? Some machines may take up more vertical space, while others require a wider extension floor area. Allocate enough room for the production staff to move around easily without hazard issues. If the facility needs more space, consider outsourcing the supply chain via contract packaging. A machine’s physical attributes directly influence the space needed for installation and operation.

Before acquisition, measuring the allocated space is imperative to ensure the machine will fit comfortably. Account for additional space around the machine for maintenance, operation, and safety clearances. Understanding the machine’s weight is vital, especially if it’s to be placed on elevated platforms or requires reinforced flooring. Heavy machinery may also have implications for transport and installation logistics.

- Electrical Requirements: Machines vary in their voltage and amperage demands. Ensuring that the facility’s electrical system can support the machine’s requirements is essential. Additionally, consider the need for backup power systems or surge protectors.

- Pneumatic and Hydraulic Systems: If the machine operates using air pressure or hydraulic fluids, confirm that the necessary connections and systems are in place. This might include compressors for pneumatic systems or pumps and reservoirs for hydraulics.

- Infrastructure Layout: Planning the layout for electrical, pneumatic, or hydraulic lines can help ensure efficient operation and ease of maintenance. Proper layout can also reduce potential hazards.

- Temperature: Some machines may have specific operating temperature ranges to ensure optimal performance. Excessive heat or cold can affect the machine’s efficiency and lead to premature wear or malfunctions.

- Humidity: Excessive moisture or dry conditions might influence the machine’s operation, especially if it handles sensitive products or materials. It’s important to maintain recommended humidity levels, possibly using dehumidifiers or humidifiers.

- Cleanliness: Dust, debris, and contaminants can impact the packaging process, potentially damaging the machine or compromising the packaged products. Ensuring a clean installation environment, possibly with air filtration systems or regular cleaning schedules, can mitigate these risks.

Environmental and Sustainability Considerations

Many organisations take ESG matters seriously, requesting suppliers and distributors within their supply chain declare their ESG practices. Rather than being reactive to such policies, be proactive when purchasing and ensure keeping the environment clean by reducing waste output. The rotary compact premade pouch machine is known to reduce waste as they have an automated sensor detector to ensure goods are filled correctly.

Assessing the amount of energy a machine uses during its operation can offer insights into its efficiency. Machines designed with modern energy-saving technologies tend to consume less power. Features like sleep modes or automatic shutdown during inactivity can reduce energy usage. It’s essential to consider machines that optimise power usage without compromising performance.

- Compatibility with Sustainable Materials: Some modern packaging materials are designed to be biodegradable or derived from renewable sources. Ensuring a machine’s compatibility with such materials is crucial for businesses aiming to be environmentally conscious.

- Adaptive Technology: As packaging trends evolve, having a machine that can adapt without requiring extensive modifications is beneficial. This might include software updates or modular components that accommodate new materials or packaging designs.

- Lifecycle Assessment: Considering the entire lifecycle of the machine – from manufacturing and operation to disposal – can offer insights into its overall environmental impact. Machines built with sustainability in mind tend to have a lower environmental footprint throughout their lifecycle.

Safety Measures

All machinery comes with inherent risk, and it is recommended to do a risk assessment to ensure the safety of employees and their working environment. To create a safe space, go through all the safety measures with the packaging vendor. Protect employees and minimise workplace accidents with workplace safety equipment.

- Emergency Stop Buttons: These allow operators to immediately halt the machine’s operations in case of an issue.

- Guarding and Interlocks: Protective barriers and interlocks prevent access to moving parts, reducing the risk of injury.

- Safety Compliance: Ensure the machine meets or exceeds local and international safety standards. Certifications from recognised bodies can be an indicator of a machine’s safety features.

- Operator Alerts: Features like alarms, warning lights, or buzzers can notify operators of malfunctions or potential safety issues.

Cost of a Packaging Machine

Aside from the initial cost of the investment, there are other long-term costs to consider, such as maintenance and operation fees, labour, electricity consumption, and depreciation. Identify the budget for the packaging machine and whether to pay entirely in cash or instalments.

Leasing the asset allows more cash flow for the business but would increase overall costs with the additional interest rates by the end of the lease. Arrange for the vendor representative to visit the production area and analyse the packaging line for them to make the best recommendation.

- Machine Type and Size: Basic machines, or those designed for smaller operations, are less expensive than complex or larger-scale equipment.

- Features and Customizations: Advanced features, automation levels, or custom modifications can significantly increase the purchase price.

- Infrastructure Modifications might include electrical upgrades, reinforced flooring, or additional ventilation systems.

- Professional Installation: Depending on the complexity, you might need specialists to install and calibrate the machine.

- Energy Consumption: A machine’s energy efficiency can impact monthly utility bills.

- Materials: The cost of packaging materials, especially using specialised or sustainable options.

- Labour: Consider the manpower needed to operate and supervise the machine. Automated machines reduce labour costs but require specialised oversight.

- Initial Training: Staff might require comprehensive training when the machine is installed.

- Ongoing Training: Additional training might be necessary if staff turnover occurs or the machine is upgraded.

Obtain quotes from different vendors and review various types of packaging machines that best meet operational requirements. Review each step carefully with detailed research before buying a packaging machine.

Find out if the packaging vendor has an after-sales service team to assist with all related queries after the purchase, such as organising training for the staff to operate the machine efficiently, emergency maintenance, or availability of spare parts to ensure the machine works optimally.

Conclusion

Purchasing a packaging machine is a significant investment that requires careful consideration of various factors. From understanding specific packaging needs and the machine’s features to considering environmental implications and cost dynamics, every aspect plays a pivotal role in ensuring the right choice.

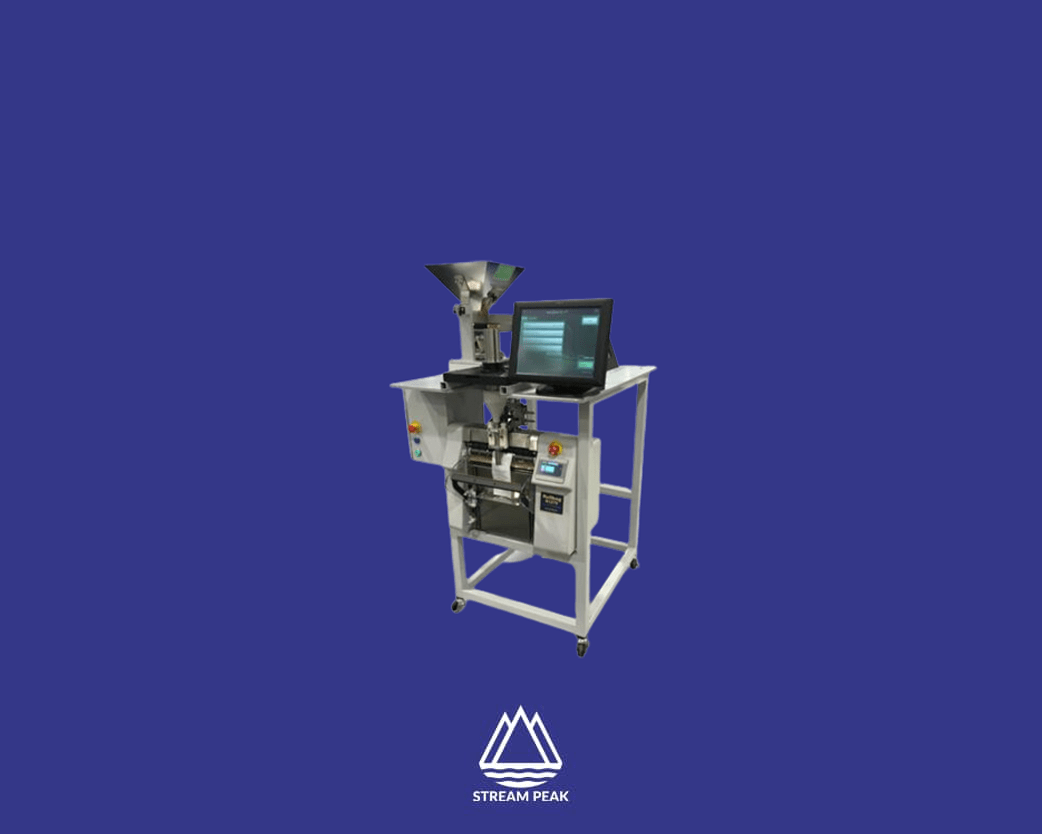

Stream Peak specialises in providing a range of automated packaging machines tailored to fit the diverse needs of various industries. To ensure that users can maximise the potential of these machines, we offer in-depth training adjusted to specific business requirements.

Recognising the importance of machine upkeep, our maintenance services include regular checks and an immediate response system for any repair needs. Moreover, our team conducts a detailed assessment of packaging requirements for businesses seeking guidance on the right packaging solutions and provides direct recommendations. Contact us for a no-obligation consultation with our packaging engineers.