How does a Chamber Vacuum Sealer work? Its Uses & Benefits

Chamber vacuum sealers are appliances designed to remove air from packaging bags or containers to create an airtight seal. Unlike external vacuum sealers, chamber vacuum sealers operate within a sealed chamber, making them versatile and efficient in various applications.

Chamber vacuum sealers preserve and protect a wide range of products, from food to medical supplies. They offer convenience, cost savings, and sustainability benefits in today’s fast-paced world. Whether individuals are chefs looking to enhance culinary skills or businesses aiming to optimize packaging processes, chamber vacuum sealers can be used in both industries and households.

Understanding Chamber Vacuum Sealers

Chamber vacuum sealers are designed for vacuum packaging applications requiring maximum air removal to extend shelf life. Due to their adaptability and effectiveness, the packaging machines are frequently used in sous vide cuisine (an innovative cooking technique in which food is vacuum-sealed and slow-cooked in water at constant low temperatures until it’s perfectly cooked through), supermarkets, and the commercial industry.

These vacuum sealers come with a transparent lid with a deep-drawn stainless steel chamber (no welded corners), providing optimal hygiene. A quick change seal bar allows for easy maintenance and reduced downtime. Furthermore, they also can be equipped with various options, including gas flush for modified atmosphere packaging and vacuum level sensors to ensure the same vacuum level is achieved every cycle. A typical chamber vacuum sealer comprises several essential components:

- Vacuum Chamber: This is the heart of the machine, where the sealing process occurs. It is a hollow chamber with a sealing bar and a transparent lid that allows users to monitor the sealing process.

- Vacuum Pump: The vacuum pump creates a vacuum within the chamber by removing air. It draws air out of the chamber and creates the necessary low-pressure environment.

- Sealing Bar: The sealing bar, often made of heated metal, is responsible for sealing vacuum bags or containers. It melts the bag’s opening, creating an airtight seal once the air is evacuated.

- Control Panel: Modern chamber vacuum sealers have user-friendly control panels that allow users to set parameters such as sealing time, vacuum strength, and sealing temperature.

- Vacuum Gauge: A vacuum gauge visually represents the vacuum level inside the chamber, ensuring precision during the sealing process.

Importance of Vacuum Sealing

Chamber vacuum sealers offer a range of benefits that enhance food preservation, reduce waste, save money, and provide safe packaging solutions. Whether used in a commercial setting or for household purposes, the packaging sealers extend the life and quality of a wide range of products.

Extended Shelf Life of Food and Other Products: Vacuum packaging machines effectively remove air from packages, slowing spoilage. By removing air, these sealers inhibit the growth of bacteria and fungi, keeping food fresh for longer periods. This extends the shelf life of food, preventing freezer burn and preserving the quality of non-food items like electronics or collectables.

Preservation of Flavor and Nutrients: By sealing products in an airtight environment, industrial vacuum sealers maintain the flavour, texture, and nutritional value of food. This preservation ensures that meals remain fresh and tasty even after extended storage.

Reduction of Food Waste: Vacuum sealing minimizes food waste by preventing spoilage and deterioration. It enables households to buy in bulk, store leftovers, and extend the life of perishables, reducing the need for frequent grocery shopping.

Cost Savings in Bulk Packaging: Businesses benefit from by optimizing packaging materials and minimizing product loss due to spoilage. The ability to buy in bulk and package items efficiently translates into significant cost savings.

Hygienic and Safe Packaging: Vacuum-sealed packages are airtight and tamper-evident, ensuring product safety and hygiene. This is particularly crucial in industries where product integrity and consumer safety are paramount, such as food and pharmaceuticals.

Uses of Chamber Vacuum Sealers

Chamber vacuum sealers are versatile machines with a wide range of culinary and industrial applications. These machines can be used in applications beyond those mentioned, including preserving collectables, electronics, and valuable documents. Whether in the kitchen or industrial facilities, vacuum sealers improve food safety, product quality, and cost-effective packaging solutions.

These machines help maintain the sterility of medical instruments, equipment, and pharmaceutical products. They create a sterile barrier by vacuum-sealing items in a controlled environment, ensuring they remain contamination-free until needed.

Vacuum packaging machines are used in the kitchen to preserve and extend various foods’ shelf life. Removing air from packaging prevents oxidation and bacterial growth, keeping food fresher for longer periods. This is particularly useful for preserving seasonal produce, meats, and dairy products.

In commercial and industrial settings, the sealers are used for packaging perishable goods such as meat, fish, poultry, and dairy products. By removing air and sealing packages airtight, they extend the shelf life of these products, reducing food waste and improving product quality.

Explanation of Operation

The operation of a chamber vacuum sealer is a precise and systematic process that ensures the creation of an airtight seal. Firstly, fill a vacuum bag with goods and place it inside a specialized vacuum bag or container. If the product is not too heavy, use the insert plates to ensure the load is accurately positioned on the seal bar and a faster vacuum cycle. Ensure that the open end of the bag or container is positioned within the vacuum chamber, ready for sealing.

When the bag sticks out of the chamber during the sealing cycle, the air inside the bag cannot escape as the surrounding pressure is reduced. If the pressure inside the bag exceeds the pressure inside the chamber, the bag will appear to swell. If the two differences become too significant, the bag will rupture, causing a mess.

Next, close the transparent lid of the vacuum chamber securely. This step is crucial to create a sealed environment within the chamber. When the lid on the machine is closed, the pump extracts air from the vacuum chamber and oxygen from the package. The entire chamber will be vacuumed, resulting in equal pressure inside the vacuum bag and across the chamber.

Simultaneously, the sealing bar within the chamber heats up and engages with the open end of the vacuum bag or container. The bag must be sealed shut at the end of the vacuum-sealing cycle to prevent air from re-entering the bag. The heat generated by the sealing bar melts the bag or container’s opening material, creating a hermetic and airtight seal. This process ensures that no air can re-enter the sealed package.

The valve opens when the sealing is complete and the chamber is refilled with air. Air cannot enter the bag because it is sealed tight, and atmospheric pressure causes the plastic bag to collapse securely over the product, completing the sealing cycle. Once the sealing process is complete, the vacuum pump stops drawing air out, and the chamber gradually returns to atmospheric pressure.

After these steps are completed, the vacuum-sealed package is revealed inside the chamber, with its contents now protected from external air and environmental factors. For various sizes and types of bags, multiple seal configurations are achievable.

Tips for Using the Chamber Vacuum Sealer

By following these tips for proper sealing techniques, regular maintenance, and addressing common issues, one can maximize the effectiveness and longevity of their chamber vacuum sealer. Whether used in a culinary or commercial setting, a well-maintained vacuum sealer ensures reliable sealing and preservation of products.

Proper Sealing Techniques:

- Proper Bag Placement: Ensure that the open end of the vacuum bag or container is correctly positioned within the chamber for sealing. Proper placement is crucial for achieving a secure and airtight seal.

- Bag Folding: When sealing liquids or moist items, fold the top to prevent liquids from entering the sealing area. This helps maintain a clean and effective seal.

- Avoid Overfilling: Do not overfill bags or containers, as this can hinder sealing and lead to imperfect seals. Leave enough space to accommodate the product and allow for proper sealing.

- Use Quality Bags: Invest in high-quality vacuum bags or containers designed for chamber vacuum sealers. Low-quality materials may not provide a reliable seal.

Maintenance and Care of the Machine:

- Regular Cleaning: Clean the vacuum chamber, sealing bar, and gaskets regularly to prevent the buildup of debris and residue. This ensures a clean and effective sealing process.

- Oil Maintenance: If your chamber vacuum sealer requires lubrication, follow the manufacturer’s recommendations for oiling the pump. Proper lubrication ensures smooth and efficient operation.

- Gasket Inspection: Check the condition of the gaskets (seals) in the chamber. To maintain a proper vacuum seal, damaged or worn-out gaskets should be replaced promptly.

- Keep It Dry: Avoid introducing excess moisture into the vacuum chamber, as this can affect the vacuum pump’s performance and lead to maintenance issues.

Troubleshooting Common Issues:

- Inadequate Vacuum: If the vacuum seal appears weak or incomplete, check for wrinkles or folds in the bag, ensure proper bag placement, and inspect the gaskets for damage. Adjusting the sealing time and vacuum strength settings may also help.

- Bag Puncture: Be cautious when sealing sharp or pointed items to prevent bag punctures. Consider using protective padding or additional layers of packaging for such items.

- Sealing Bar Maintenance: If the sealing bar fails to heat properly, it may result in weak seals. Clean the sealing bar and check for any damage or wear. Consult the user manual for guidance on adjusting sealing temperature and pressure settings.

- Pump Noise: Unusual noises from the vacuum pump may indicate maintenance issues. Inspect the pump for loose parts, oil levels, or signs of wear and consult the user manual for troubleshooting guidance.

Conclusion

Chamber vacuum sealers operate systematically, involving components like the vacuum chamber, vacuum pump, sealing bar, and control panel. This process ensures the creation of airtight seals, preserving the quality and freshness of various products.

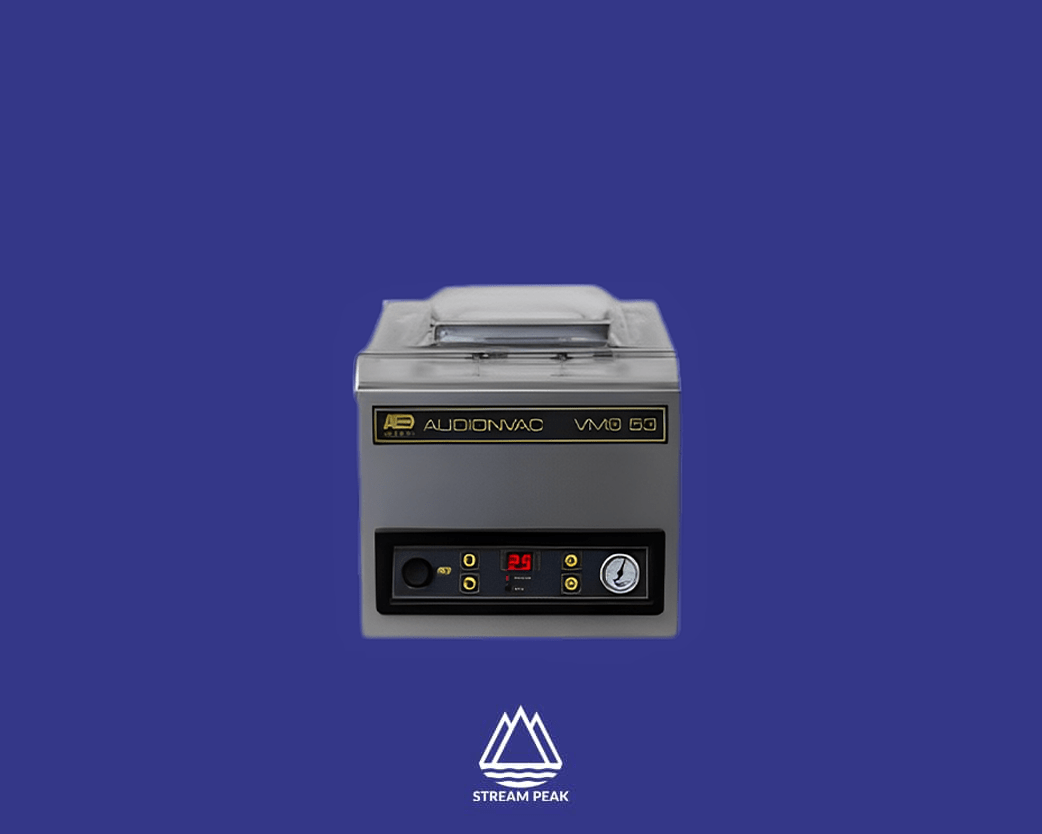

Stream Peak offers high-quality industrial chamber vacuum sealers equipped with user-friendly controls. Our machines feature a compact design that minimizes space requirements and provides optional gas flush capabilities for modified atmosphere packaging. You won’t need compressed air or special connections, and our easy-to-read display ensures seamless operation. Contact our packaging engineers today to schedule a no-obligation appointment to find out more.