Cold Chain Packaging Solutions for Healthcare and Life Sciences

Cold chain packaging solutions have become increasingly important in recent years as the demand for temperature-sensitive products continues to grow. While cold chain packaging is essential for any industry looking to transport perishable goods, it’s especially crucial for the healthcare and life sciences industries.

Many products, such as vaccines, medications, and biological samples, require temperature control during transportation and storage to maintain their safety and efficacy. This is where cold chain packaging comes in – it is designed to maintain a specific temperature range, ensuring that the contents are protected from temperature fluctuations that could compromise their quality.

The numbers are staggering: on average, it is estimated by logistics experts that the biopharma industry makes an average loss of $35 billion yearly because of spoilages due to temperature deviations. Therefore, providing the proper storage and transport of goods in temperature-controlled logistics is crucial. Let’s learn more about cold chain packaging and the solutions available for healthcare and life sciences.

What is the role of packaging in cold chain transportation?

Cold chain packaging describes packing and shipping goods at an appropriate, consistent temperature. The goal is to ensure that goods are kept at the same temperature from manufacturing to the final destination.

Manufacturers design cold chain packaging solutions to keep the internal products cool via insulation and other materials. The coolness ensures that transported assets remain within set conditions.

Types of cold chain packaging solutions available

Cold chain packaging is critical to ensuring the safe transport and storage of healthcare and pharmaceutical products that require temperature control. Some solutions available for cold chain packaging in healthcare and pharmaceutical sciences include:

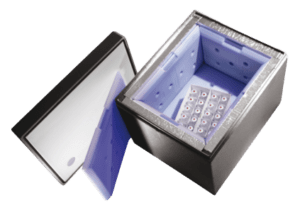

I nsulated packaging: Insulated packaging is designed to maintain a stable temperature inside the package, protecting the contents from temperature fluctuations outside. This packaging includes expanded polystyrene (EPS), polyurethane foam, or vacuum-insulated panels (VIPs).

nsulated packaging: Insulated packaging is designed to maintain a stable temperature inside the package, protecting the contents from temperature fluctuations outside. This packaging includes expanded polystyrene (EPS), polyurethane foam, or vacuum-insulated panels (VIPs).

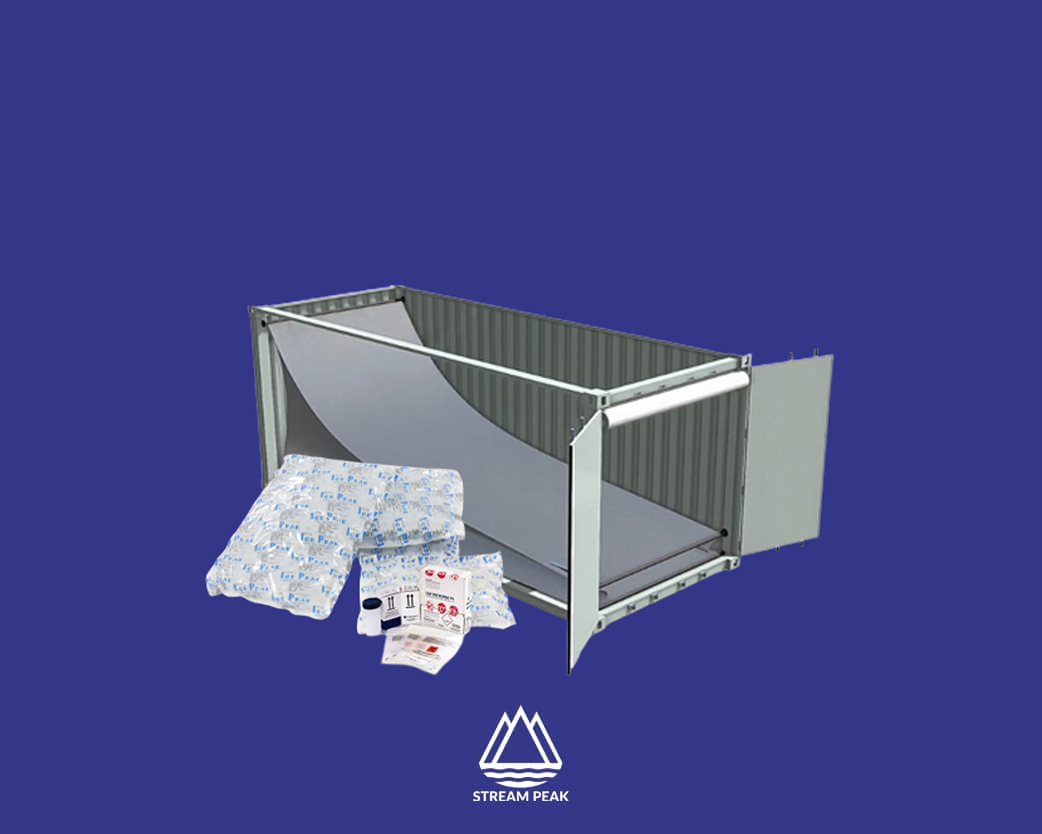

Phase change materials (PCMs): PCMs are materials that absorb or release heat to maintain a consistent temperature. Businesses can use them in packaging to maintain the temperature of the contents during transportation or storage. For example, PCM products like the Thermal Liner Embatuff can protect cargo during transport by keeping a temperature difference of 10-20ºC between the container and the interior.

Active temperature-controlled packaging: Active temperature-controlled packaging uses a power source to regulate the temperature inside the package actively and can be monitored using temperature packaging indicators. This packaging typically uses refrigeration or heating elements to maintain the desired temperature.

Temperature monitoring and tracking systems: Temperature monitoring and tracking systems can monitor the temperature of the contents during transportation or storage. These data loggers can alert users to temperature deviations that could compromise the integrity of the product.

Dry ice: Dry ice maintains the temperature of frozen products during transportation. Dry ice vaporises into carbon dioxide gas, which can help to maintain a low temperature.

Refrigerated shipping containers: Refrigerated shipping containers are insulated containers transporting products requiring temperature control. These containers typically use a refrigeration unit to maintain a consistent temperature. However, more technologically advanced options now exist to transform an ordinary container into a cooler box without a refrigerated unit.

One example of such technology is the Insulated Air Liner. The Air Liner is an insulated box liner that can be inflated with air or inert gases to convert a standard cardboard box into a cooler box. It provides thermal insulation and helps to maintain the cold chain during transportation.

Gel packs and ice packs: Gel packs and ice packs maintain the temperature of refrigerated products during transportation. These ice gel packs are typically placed inside the insulated packaging to help keep the desired temperature.

They are commonly used with thermal insulating boxes and temperature/ humidity data recorders to ensure smooth delivery during transportation. In addition, it helps prevent bacteria growth and spoilage, ensuring that goods remain in good condition.

Ultimately, the choice of cold chain packaging solution will depend on the product’s specific needs and the transportation and storage conditions. Knowing what the product requires and the necessary logistic requirements will help businesses decide which cold chain packaging solution to use.

Why is cold chain packaging important for healthcare and life sciences?

Pharmaceutical products are susceptible to damage from environmental factors such as heat, humidity, light, vibrations, and shocks. Therefore, every step must be risk-free, from research to final sales. This extends to transporting and storing raw materials and the final product. Any disruption in this temperature or mishandling of the product could result in ineffective medications, vaccines, and other temperature-sensitive products.

For instance, the Journal of Pharmaceutical Policy and Practice highlights in a research paper that businesses must practice efficient cold chain management when transporting time-sensitive pharmaceutical products like the COVID-19 vaccine. The Ppfizer-BioNTech vaccine requires ultra-cold chain supply transportation and storage at -70 degrees Celsius. Dry ice, temperature-controlled insulation, and appropriate storage facilities at the port are just some cold-chain logistics necessary for successful vaccine delivery.

Therefore, such case studies show that companies developing or transporting such temperature-sensitive products must pay special attention to cold chain packaging. The loss of these products could lead to valuable data loss, reputation risk to the company, and regulatory action.

Key Considerations in Selecting Cold Chain Packaging

The cold chain, vital for preserving the quality and safety of temperature-sensitive products, relies heavily on its packaging. Selecting the right packaging solution is instrumental in maintaining the efficacy of healthcare and life sciences products.

Performance: Knowing how long the packaging can consistently maintain the required temperature is vital. This duration should ideally surpass the time it takes for the product to reach its final destination. Factors like external ambient temperature, transit duration, and potential delays should be considered.

Usability: A good cold chain packaging solution should be user-friendly. It should allow for quick and efficient packing, minimising the time products spend outside their temperature-controlled environment. Reusable packaging solutions, while potentially having a higher upfront cost, can offer cost savings in the long run and reduce environmental waste. Single-use packages might be more convenient for certain applications but can generate more waste.

Sustainability: Evaluate the materials used in packaging. Are they derived from sustainable sources? What’s the carbon footprint associated with the manufacturing and transportation of these packages? Opt for recyclable packaging materials, or if they’re single-use, ensure they can be disposed of with minimal environmental impact.

Cost Efficiency: Assess the upfront costs of the packaging solution. While some advanced solutions might seem expensive initially, they offer better performance and thus justify the investment. Beyond the direct cost of the packaging, consider the potential savings it could bring. For instance, reusable packaging might offer cost benefits in the long run. Similarly, more efficient insulation might reduce the need for expensive refrigerants, leading to overall savings.

Conclusion

Effective cold chain packaging solutions are essential to the healthcare and life sciences industries, as they play a critical role in maintaining the safety and efficacy of products. Selecting packaging solutions that support the required temperature range is essential for safe transportation. Businesses should also monitor and track the temperature to ensure the product’s safety and efficacy.

Stream Peak is a trusted supplier in cold chain logistics, offering advanced and reliable packaging solutions tailored for temperature-sensitive products. Our designs prioritise efficiency and sustainability, ensuring products remain safe during transit while minimising environmental impact. Contact our packaging engineers to discuss your specific needs and discover the most effective solutions.