How Vacuum Sealing Reduces Food Waste?

In 2021, Singapore generated approximately 817 thousand tonnes of food waste. Food waste accounts for one-tenth of Singapore’s total trash production. Around 19% of the food waste generated in that year was recycled. The primary cause of food waste is that most consumables have a limited shelf-life.

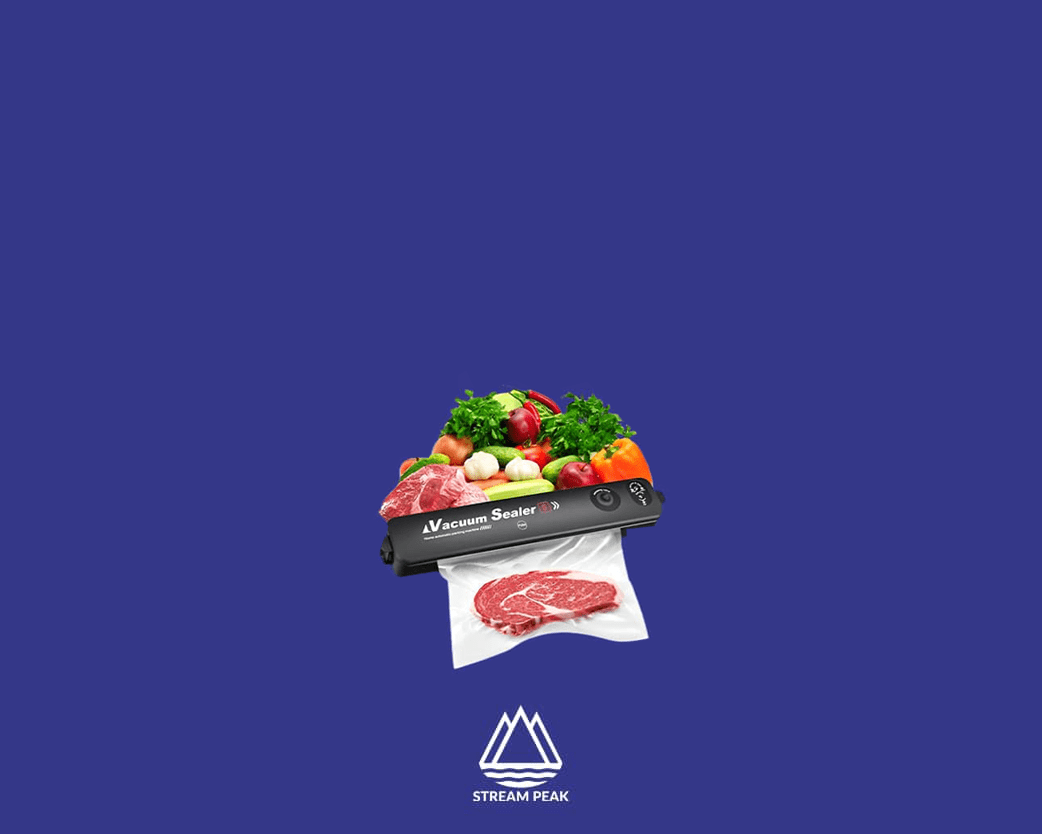

There are several ways to extend the shelf-life of fresh goods, and one method would be to use vacuum packaging. Simple household vacuum sealers and bags can significantly prolong food storage. Food waste raises food prices because it increases demand, and with a little effort, vacuum-sealed food items can help save time and money.

How can Vacuum Sealing reduce food waste?

Vacuum sealing creates a modified atmosphere within the package. For sealants intended for domestic use, the adjusted atmosphere contains less oxygen. Removing air with the vacuum sealer reduces the oxygen content of the box. Because of the lower oxygen level, fresh goods can be stored for extended periods. The shelf-life is significantly extended when combined with desiccants or oxygen absorbers.

Prevent freezer burns

Freezer burn occurs when frozen food is exposed to air, causing dehydration and oxidation. This is evident when ice crystals form on the surface of the food. Over time, these ice crystals can change the molecular structure of the food, especially on the exposed surface. The result is a change in the food’s colour, texture, and overall quality. The affected portions often appear dry or leathery and can develop a distinct, off-taste.

Vacuum sealing technology extracts most of the air from a package before sealing it. Doing so significantly reduces the trapped moisture that can form ice crystals. Consequently, the environment inside a vacuum-sealed bag becomes unfavourable for the development of freezer burn.

Vacuum-sealed bags provide a barrier between the food and any external air, ensuring minimal exposure even over extended periods. This protection and the removal of internal air make vacuum sealing one of the most effective methods for preventing freezer burn. As a result, the food retains its original quality, nutritional content, and flavour longer than traditional freezing methods.

Inhibition of Bacterial Growth

Perishable foods, by definition, have a limited shelf life due to their susceptibility to spoilage. One of the most common culprits behind this spoilage is the growth of bacteria, fungi, and other microorganisms that can deteriorate the food’s quality, safety, and nutritional value.

Oxygen plays a critical role in the lifecycle of many bacteria and fungi. These organisms, termed “aerobic,” rely on oxygen to perform their metabolic activities. As they metabolise, they can produce waste products detrimental to food, altering its taste, texture, smell, and safety.

Vacuum sealing operates by extracting most of the air from a package before sealing. Since the atmosphere is composed of approximately 21% oxygen, its removal substantially limits the oxygen availability within the sealed environment. This lack of oxygen creates a challenging environment for aerobic bacteria and fungi, hindering their growth and reproduction.

Eliminating microbial growth directly translates to a longer shelf life for perishable foods. Without the rapid multiplication of spoilage organisms, the food retains its original quality and safety for an extended period. It’s worth noting that while vacuum sealing dramatically reduces the growth of aerobic microorganisms, it might provide a more favourable environment for anaerobic bacteria, which don’t require oxygen.

Preservation of Flavor, Color, and Nutrients

Flavour, an integral part of the eating experience, arises from a complex interplay of various chemical compounds. Oxidative reactions, facilitated by the presence of air, can degrade or transform these flavour compounds. For instance, fats and oils in food can oxidise, producing off-flavours and reducing the food’s palatability. Vacuum sealing reduces oxygen exposure, thus preserving the integrity of these flavour molecules and maintaining the food’s original taste.

When food is exposed to air, several detrimental reactions can occur. Oxygen, a major component of air, can react with various compounds in the food, leading to oxidative changes. These reactions can alter the molecular structure of flavour compounds, pigments, and vital nutrients, compromising the food’s quality and nutritional value.

Specific pigments, such as chlorophyll in vegetables or myoglobin in meats, determine the colour of many foods. Oxygen can alter these pigments. For example, myoglobin oxidation turns meat to a brownish colour instead of its typical red or pink hue. Minimising oxygen contact through vacuum sealing can substantially reduce these oxidative colour changes, retaining the food’s natural and appealing colour.

Oxygen exposure can also lead to the degradation of essential nutrients. Vitamins, such as vitamin C and some B vitamins, are particularly sensitive to oxidation. Over time, the nutritional profile of food stored in the presence of air can diminish. Vacuum sealing acts as a barrier, safeguarding these valuable nutrients and ensuring the food remains nutritionally rich.

The vacuum sealing process involves the extraction of most of the air from a package before sealing it. This removal significantly limits the amount of oxygen in contact with the food. The sealed environment then acts as a protective barrier, preventing further air and contaminants from entering and interacting with the food.

Protection from Physical Damage

The freedom of movement, especially when combined with external pressures, can lead to physical damage such as bruising, crushing, or deformation. Such damage can adversely affect the food’s appearance, texture, and quality.

Vacuum sealing involves extracting most of the air from a package, resulting in a tightly sealed environment around the food. The lack of air inside ensures that the food is held firmly in place, wrapped snugly within the confines of the packaging material.

The strength and durability of vacuum-sealed packages contribute to their protective capacity. The materials used in these packages are typically designed to be flexible and robust, ensuring that they mould around the food while resisting punctures or tears.

Minimising physical damage has direct implications for food preservation. Damaged areas in food can become entry points for bacteria and other spoilage organisms, leading to faster degradation. Moreover, physically damaged food often loses moisture faster, leading to undesirable changes in texture and freshness.

Bulk Buying and Portioning

Using a vacuum sealer machine, one can purchase food in bulk and repackage it into smaller pieces. Food purchased in bulk saves money, and vacuum sealing is far more efficient than resealable bags. The food can then be stored longer and is often used in butcher shops and meat processing plants.

Portioning food into desired amounts immediately after a bulk purchase aids in efficient storage and consumption. Designating specific quantities for future use minimises waste as only the necessary amount is accessed at a given time, leaving the rest undisturbed and fresh.

By leveraging the combined advantages of bulk buying, portioning, and vacuum sealing, food consumption becomes more sustainable. It ensures optimal utilisation of purchased items, reducing the frequency of spoilage and cutting down on overall food waste.

Save leftovers and Seasonal Items

On special occasions like Christmas and birthdays, leftovers may be plentiful—vacuum-seal bits to make a quick, ready-to-eat meal. According to a 2018 Yahoo Finance article, families spend an average of $150 on Christmas and Thanksgiving dinners. Many larger families spend significantly more depending on the size and number of visitors. Saving 20–30% without wasting food can cover the cost of a vacuum sealer and bags.

One of the best uses for vacuum sealers is to save seasonal foods like berries, tomatoes, and other vegetables for out-of-season times of the year. Through internal testing (refer to the picture below) done by the Greek Cold Storage & Logistics Association, they have successfully kept frozen zucchini, peas, and squash for over a year. For home gardeners, the capacity to support locally grown food for longer is ideal.

Other ways to reduce food waste

Limit food waste in other ways other than vacuum-sealing food. Here below are some methods:

- Before going grocery shopping, make a thorough list of everything required. It is usually a good idea to calculate the purchase amounts before shopping—select products that can be repackaged and stored without losing quality.

- Use proper food storage, particularly for items in the pantry. For bulk purchases, use older products first to avoid expiration. The first-in-first-out principle, when applied correctly, will help to prevent wastage. If the item is stored for a long, ensure the container is sealed completely to prevent air and pests from entering.

- Consider labelling food with the date as well as the item.

Conclusion

Use vacuum-sealing to maintain food freshness, reduce waste, and extend the shelf life of the food. When shopping for vacuum-sealed bags, seek textured rolls or bags. The textures in the bag facilitate the quick passage of air while vacuuming. Bags without texture are unsuitable for use with vacuum sealing machines. The advantages of vacuum sealing food extend beyond cost and time savings to benefit the environment by reducing waste.

Stream Peak offers vacuum-sealing machines designed for both individual and commercial needs. These machines efficiently extract air, extending food preservation. They handle various food items, from meats to vegetables, and feature an easy-to-use interface. Made with durable materials, they work with multiple vacuum bag types, including textured ones. Contact us and schedule an appointment with our packaging engineers for a no-obligation demonstration.