Complete Guide To Activated Alumina Desiccants

Activated alumina is a versatile and highly effective adsorbent and catalyst that finds extensive use in various industrial and environmental applications. It is a porous material derived from aluminium oxide (Al2O3), which undergoes a specific activation process to create a large surface area and an intricate network of interconnected pores.

These unique characteristics give activated alumina exceptional adsorption and catalytic properties, making it a valuable material in diverse fields. In this article, we will share more on activated alumina, exploring their composition, working principles, diverse applications, and the environmental impact they make.

Understanding Activated Alumina

Activated alumina is primarily known for its high surface area-to-weight ratio, resulting from the controlled activation process. This process involves heating aluminium hydroxide or other aluminium compounds at high temperatures, causing them to undergo dehydration and transformation into gamma-alumina.

The activation process forms many pores and channels within the material, giving it an enormous internal surface area, typically ranging from 150 to 300 square meters per gram.

The desiccant’s pore structure can be tailored to specific applications by controlling temperature, time, and impurities during activation. This versatility allows manufacturers to produce activated alumina with varying pore sizes and surface areas to suit different adsorption and catalytic requirements.

Properties and Structure

Activated alumina primarily comprises aluminium oxide (Al2O3), the main chemical constituent. It is an amphoteric oxide, which can act as both an acidic and basic material. The chemical formula Al2O3 reveals that activated alumina contains two aluminium atoms and three oxygen atoms bonded together. This composition imparts various properties to activated alumina, making it an excellent adsorbent and catalyst.

In addition to aluminium oxide, activated alumina may contain trace amounts of other elements, depending on the raw materials used during manufacturing. These impurities can influence the material’s adsorption and catalytic capabilities. Common impurities include silica (SiO2), sodium oxide (Na2O), and iron oxide (Fe2O3), among others.

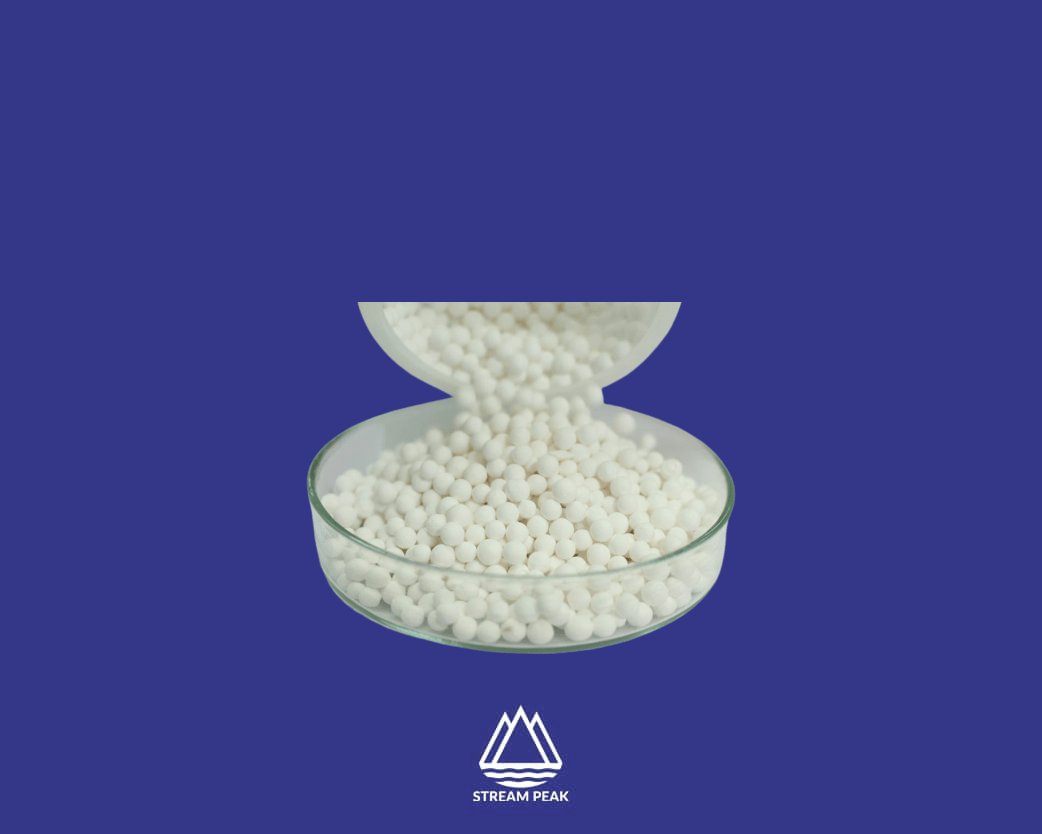

- Particle Size: The particle size of activated alumina can vary depending on the application. It is available in various forms, including beads, pellets, granules, and powders. The choice of particle size affects the material’s surface area, porosity, and adsorption capacity.

- Surface Area: One of the most critical properties of activated alumina is its high surface area. The activation creates a vast network of pores and channels, resulting in a large internal surface area. The surface area typically ranges from 150 to 300 square meters per gram, providing ample active sites for adsorption and catalysis.

- Porosity: Activated alumina is characterised by its high porosity resulting from the activated structure. The presence of many pores and voids enhances its capacity to adsorb and retain gases, liquids, and dissolved species.

- Bulk Density: The bulk density of activated alumina can vary based on the manufacturing process and the intended application. It typically ranges from 0.6 to 0.8 grams per cubic centimetre (g/cm³).

- Colour: Activated alumina is usually white or off-white, which can aid in identifying its purity and suitability for specific applications.

Applications and Benefits

The unique properties of activated alumina make it a useful desiccant in various industries and environmental settings.

- Water Treatment: Activated alumina is widely used as a water desiccant to remove impurities, such as fluoride, arsenic, and selenium, from drinking water sources. Its high adsorption capacity for these contaminants ensures safe and potable water production.

- Gas and Vapor Purification: In natural gas and petrochemical industries, activated alumina removes moisture, carbon dioxide, and trace impurities from gases and vapour streams, preventing corrosion and ensuring product quality.

- Drying and Dehydration: The material is an efficient desiccant in various applications, such as air drying, dehydration of compressed air systems, and moisture removal from liquids and gases.

- Catalyst Support: The desiccant is a robust support material for various catalytic processes. It is commonly utilised as a carrier for catalysts in oil refining, petrochemical, and chemical manufacturing industries, enhancing catalytic efficiency and stability.

- Claus Catalyst: It plays a crucial role in sulfur recovery units, where it helps convert hydrogen sulfide into elemental sulfur, mitigating harmful emissions.

- Air Purification: Activated alumina is employed in air purification systems to adsorb volatile organic compounds (VOCs) and other harmful gases, improving indoor air quality and reducing health risks.

- Water Filtration: Its adsorption capabilities are harnessed to remove impurities and contaminants from industrial wastewater, improving environmental standards and regulatory compliance.

- Chromatography: The desiccant is utilised in chromatographic separation techniques to separate and analyse complex mixtures.

Adsorption Capabilities of Activated Alumina

Activated alumina possesses exceptional adsorption properties, making it a valuable material for various applications. Its unique structure with a high surface area and abundant pore network enables efficient adsorption of various substances, including water, gases, and vapours.

The desiccant’s adsorption capabilities make it versatile in water treatment, gas purification, and desiccant applications. Its widespread use in various industries as an efficient and reliable adsorbent improves process efficiency, product quality, and environmental protection.

Water Adsorption

One of the primary applications of activated alumina is in water treatment and purification processes. Activated alumina exhibits a strong affinity for water molecules, enabling it to effectively adsorb water from various sources, such as air, gases, and liquids. This property makes it an efficient desiccant for removing moisture and humidity in industrial processes and compressed air systems.

In water treatment, the desiccant is particularly useful for removing fluoride, arsenic, and other contaminants from drinking water sources. As water passes through a bed of activated alumina, fluoride ions are adsorbed onto the material’s surface, producing safe and potable water. This process is commonly employed in municipal water treatment facilities and regions with high fluoride concentrations in natural water sources.

Gas and Vapor Adsorption

Activated alumina’s high surface area and porosity make it suitable for gas and vapour adsorption. It is widely used in natural gas and petrochemical industries to remove moisture, carbon dioxide, sulfur compounds, and other trace impurities from gases and vapour streams. These impurities can cause corrosion and interfere with downstream processes, affecting the quality and efficiency of the final products.

In industrial gas purification applications, activated alumina acts as an effective adsorbent for removing acidic gases, such as hydrogen sulfide, sulfur dioxide, and various organic compounds. Its ability to selectively adsorb specific gases and vapours improves product purity and reduces environmental emissions.

Desiccant and Purification Applications

Activated alumina is a highly efficient desiccant in various applications requiring moisture removal. Its desiccant properties are harnessed in the pharmaceutical and chemical industries’ compressed air dryers, gas drying systems, and dehydration processes. As an adsorbent, activated alumina can achieve low dew points, making it suitable for critical drying applications where even trace amounts of moisture can be detrimental.

The material’s adsorption capabilities extend to the purification of liquids and gases, such as natural gas, air, and industrial process streams. Activated alumina is commonly used to remove impurities, such as water vapour, hydrogen sulfide, and volatile organic compounds (VOCs), from these streams, ensuring product quality and compliance with industry standards.

In air purification systems, activated alumina adsorb harmful gases and VOCs, improving indoor air quality and a healthier living and working environment. Its ability to selectively adsorb specific pollutants makes it an efficient choice for air purification in industrial and residential settings.

Safety and Handling Considerations

Activated alumina is generally considered safe to handle when proper precautions are taken. However, like any chemical substance, it is essential to follow specific safety measures to ensure workers’ well-being and the material’s integrity.

- Personal Protective Equipment (PPE): Always wear appropriate personal protective equipment, including safety goggles or a face shield, chemical-resistant gloves, and a dust mask or respirator, especially when dealing with fine powders or dust. PPE will help protect against eye irritation, skin contact, and inhalation of airborne particles.

- Avoiding Ingestion and Inhalation: Avoid eating, drinking, or smoking while handling activated alumina. Ingestion or inhalation of the material can lead to irritation and respiratory issues. If accidentally ingested, seek medical attention immediately.

- Spill Management: In the event of a spill, clean up the area promptly and carefully. Use appropriate containment measures to prevent the spread of activated alumina particles. Avoid sweeping or stirring up dust during cleanup, as it can disperse particles into the air.

- Storage: Store activated alumina in a dry, well-ventilated area away from incompatible substances, such as strong acids, bases, and reactive metals. Keep the material in its original sealed or tightly closed container to avoid contamination and moisture absorption.

- Compatibility Testing: Before using activated alumina in specific applications, conduct compatibility tests to ensure it is suitable for the intended use and will not react adversely with other materials in the system.

Conclusion

Activated alumina offers adsorption and catalytic capabilities across various industries. Its exceptional properties, including high surface area, porosity, and chemical stability, contribute to its widespread use as an adsorbent, catalyst support, and desiccant. From water treatment and gas purification to catalytic processes and industrial drying applications, activated alumina improves process efficiency, product quality, and environmental sustainability.

Focusing on providing reliable solutions, Stream Peak supplies activated alumina with tailored properties to meet various industrial and environmental applications. We conduct daily checks in our in-house QA laboratory to ensure consistent performance. Contact us to learn about the full range of activated alumina desiccant bags we manufacture in Singapore, backed by ISO 9001 and ISO 14001 certifications.