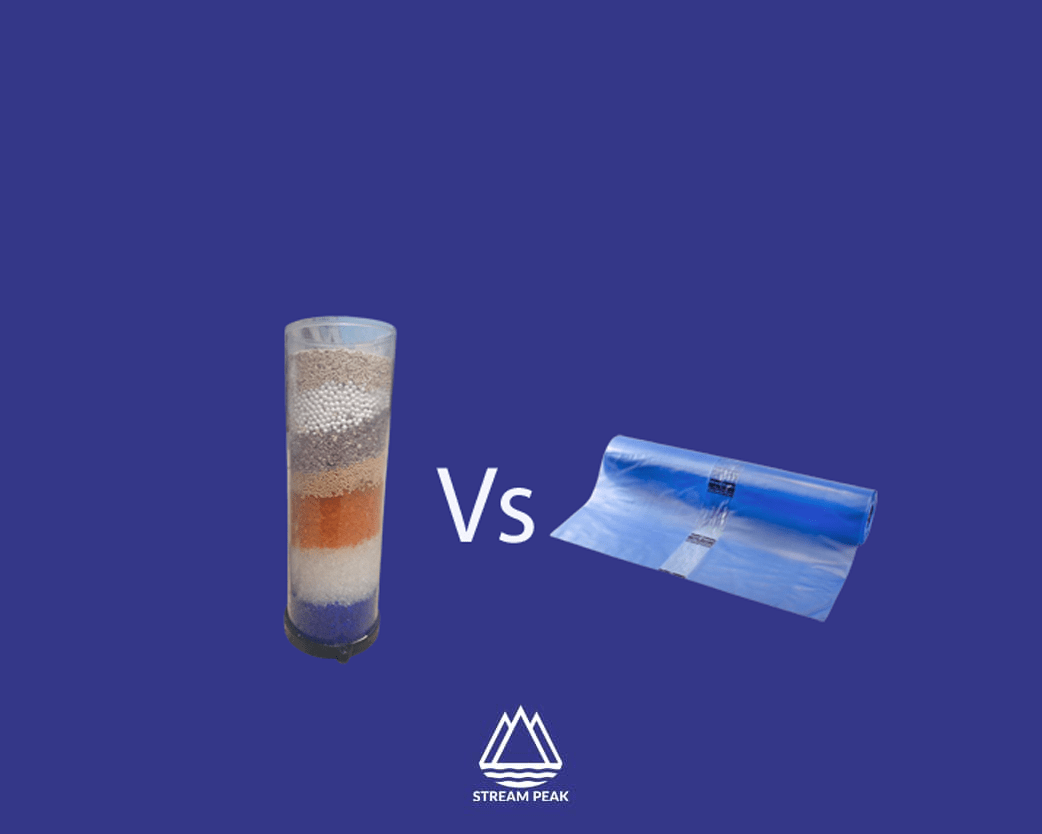

Desiccants vs. VCI: A Comparative Analysis for Rust Prevention

Rust corrodes and weakens valuable structures, equipment, and machinery across a wide spectrum of industries. From manufacturing and transportation to infrastructure and electronics, the impact of rust can be staggering, leading to operational downtime, safety hazards, and losses.

Rust is the brownish or reddish deposits that collect over metal when left under environmental conditions for some time. The chemical composition of rust is iron oxide, resulting in the combination of iron and oxygen. Iron is a highly reactive metal and combines effortlessly with environmental oxygen. Hence, measures must be taken to contact the air’s surrounding moisture to prevent metal rusting. Protective packaging solutions such as desiccants and VCI can help with it. In this article, we will compare these two packaging solutions.

Desiccants

Desiccants, often called moisture absorbers, are an integral component of the arsenal against rust and corrosion. They absorb and retain moisture from the surrounding environment. By reducing the humidity level within a confined space, desiccants create unfavourable conditions for rust formation, as moisture is a key corrosion catalyst.

When exposed to high-humidity environments, moisture in the air is drawn to the surface of the desiccant material. This moisture is trapped within the desiccant’s pores or lattice structure, leaving the immediate surroundings drier. Maintaining a low-humidity environment minimises the potential for condensation and subsequent rust formation on metal surfaces.

Benefits and Applications

Advantages: Desiccants are generally cost-effective compared to other rust prevention methods. They are easy to deploy and require minimal maintenance. Most desiccants are non-toxic, safe for various settings, and can be tailored to fit different spaces and applications.

Limitations: Desiccants have a finite moisture absorption capacity and require replacement or regeneration. The effectiveness of desiccants is highly dependent on the enclosed space’s volume and sealing quality.

Desiccants find cane used across various industries and scenarios where moisture control is paramount. Industries that handle sensitive equipment, electronics, machinery, and metals benefit from desiccant deployment.

- Manufacturing: Protection of machinery and components during storage and transportation.

- Electronics: Prevention of moisture-related damage to sensitive electronic components.

- Defence and Military: Preserving firearms, ammunition, and equipment in adverse conditions.

- Pharmaceuticals: Maintenance of product stability in moisture-sensitive medications.

- Food and Beverage: Prevention of moisture-induced spoilage in packaged goods.

Types of Commonly Used Desiccants

Several desiccant materials are widely employed in rust prevention efforts, each with unique properties and suitability for specific applications. Some common types include:

- Silica Gel: This desiccant is a porous form of silicon dioxide. It is highly effective at absorbing moisture and is available in various sizes and configurations, making it versatile for different environments.

- Clay Desiccants: These natural clay-based desiccants are cost-effective and often used in packaging applications to protect goods during transportation and storage.

- Molecular Sieves: These synthetic desiccants have finely tuned pore sizes that selectively adsorb specific molecules, including water vapour. They find applications in specialised industries like electronics and pharmaceuticals.

VCI (Vapor Corrosion Inhibitors)

Vapour Corrosion Inhibitors (VCIs) deploy a molecular-level protective shield to defend metal surfaces against rust. Through the process, these inhibitors create an invisible barrier that inhibits the electrochemical reactions responsible for corrosion, even in the presence of moisture and oxygen.

VCIs are designed to release vapour molecules into the surrounding atmosphere. These vapour molecules then adsorb onto the metal surface, forming a protective molecular layer. This layer acts as a barrier between the metal and the corrosive agents, such as moisture and oxygen, effectively hindering their interaction with the metal. VCIs provide reliable and long-lasting rust protection by interrupting corrosion-inducing electrochemical reactions.

Benefits and Applications

Advantages: VCIs provide extended protection, often lasting months or even years. They are easy to apply and integrate into existing processes. They also inhibit corrosion only on metal surfaces, leaving non-metal components unaffected. VCIs leave no residue or damage on metal surfaces when removed.

Limitations: VCIs can be relatively more expensive than desiccants, especially for large-scale applications. Factors like temperature and air circulation can influence the effectiveness of VCIs.

VCIs can be used in industries where traditional rust prevention methods may need to be more feasible and effective. Some key industries that benefit from VCI technology include:

- Automotive and Aerospace: Protecting valuable vehicle and aircraft components during transportation and storage.

- Marine: Preventing corrosion in marine equipment, vessels, and offshore structures exposed to corrosive saltwater environments.

- Electronics: Shielding sensitive electronic components from moisture-related damage.

- Military and Defense: Safeguarding weapons, equipment, and machinery in challenging operational conditions.

- Long-Term Storage: Preserving equipment and components in long-term storage or during shipment.

Types of VCI Products

VCIs are available in various forms, catering to diverse applications and industries. Some common types of VCI products include:

- VCI Emitters: These devices release VCI molecules into the air within an enclosed space, providing continuous protection to metals in storage.

- VCI Films and Papers: These materials are often used to wrap or enclose metal items, creating a controlled atmosphere that prevents rust.

- VCI Liquids and Coatings: These formulations can be applied directly to metal surfaces, creating a protective layer that repels corrosion agents.

Comparative Analysis

Both desiccants and Vapor Corrosion Inhibitors (VCIs) offer unique approaches that address varying aspects of the problem. This analysis shares the fundamental differences between these two methods, such as their strengths and limitations for rust prevention.

Rust Prevention Mechanisms

Desiccants tackle rust by curbing moisture levels in the environment, impeding the chemical reactions that trigger corrosion. They focus on creating a dry atmosphere, which is detrimental to rust formation. In contrast, VCIs disrupt corrosion by forming a protective molecular layer on metal surfaces. This layer repels corrosive agents, such as moisture and oxygen, halting their interaction with the metal and thwarting the onset of rust.

Effectiveness in Different Environments

The effectiveness of desiccants and VCIs is influenced by the environmental conditions they encounter. Desiccants work better in humid environments where moisture control is paramount. In such scenarios, they maintain low humidity levels, hindering the condensation that leads to rust. VCIs, on the other hand, are suitable in diverse environments, including fluctuating humidity and temperature conditions. Their vapour-phase inhibition is especially advantageous when protecting complex metal structures or equipment is required, as VCIs can reach hidden and hard-to-access areas.

Longevity of Protection

The period of protection is a key consideration when evaluating rust prevention methods. Desiccants possess a finite absorption capacity, necessitating regular replacement or regeneration. Their effectiveness wanes as they become saturated with moisture. In contrast, VCIs offer long-lasting protection that can endure for extended periods. Once applied, the protective layer remains intact, providing consistent rust prevention. This extended protection can be particularly beneficial for items in storage or transit.

Compatibility with Different Materials

Compounding rust prevention methods with various materials is crucial in preventing unintended damage. Desiccants are inherently safe to use across a spectrum of materials, as their mechanism relies on moisture absorption and doesn’t directly interact with the metal. This makes them suitable for a wide range of applications. VCIs, while generally safe for metals, may require careful consideration when used with certain materials or coatings. The formation of the protective molecular layer could impact surface finishes or coatings.

Conclusion

Selecting between desiccants and VCIs depends on the application’s specific requirements and the environmental conditions. Desiccants are well-suited for scenarios where moisture control is pivotal, especially in industries with relatively stable conditions. On the other hand, VCIs shine in situations that demand extended protection, fluctuating environments, and complex structures. Combining both strategies may yield synergistic benefits in some cases, providing a robust defence against rust from multiple angles.

Stream Peak offers a wide range of desiccants and Vapor Corrosion Inhibitors (VCIs) for rust prevention. Our products cater to various industries and applications. We hold ISO 9001 certification for quality and ISO 14001 for environmental management. Our desiccant bags meet rigorous standards and emphasise environmental responsibility. Contact our packaging engineers for reliable corrosion prevention solutions for industrial equipment, electronics, and stored goods.