Best Practices for Container Lashing and Securing Cargo

Container lashing and securing cargo are useful during the shipping process to ensure the safe transportation of goods across vast distances. Properly securing cargo inside shipping containers prevents shifting, damage, and potential accidents during transit. In this article, we will explore the best practices for container lashing, focusing on techniques, equipment, and considerations to optimize cargo safety and protect valuable shipments.

Definition of Container Lashing

Container lashing, also known as cargo securing, is the process of fastening and securing cargo within shipping containers or onto transportation vehicles to prevent movement, shifting, or damage during transit. It involves using various methods, equipment, and materials to restrain the cargo effectively, ensuring it remains stable and safe throughout its journey.

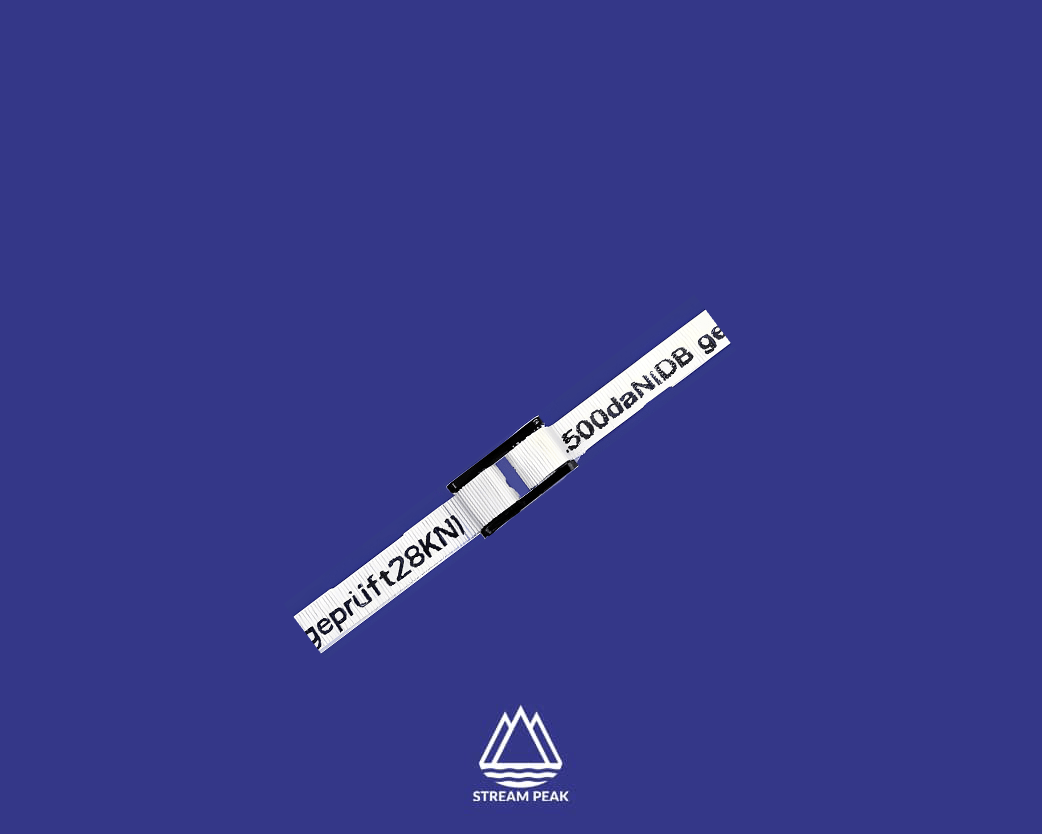

Container lashing involves the use of lashing belts, straps, ropes, wires, twist locks, turnbuckles, and other securing mechanisms to hold the cargo in place. The lashing components are carefully chosen based on the type of cargo, its weight, and the mode of transportation.

Importance of Cargo Securing

Proper cargo securing is important for safe shipping and plays a crucial role in the overall success of the logistics chain. By preventing accidents, maintaining cargo stability, complying with regulations, and protecting valuable shipments, proper lashing practices contribute significantly to the success of the shipping industry and the satisfaction of customers and stakeholders.

- Preventing Accidents and Damage: Unsecured cargo is susceptible to shifting, which can lead to imbalanced weight distribution within the container or vehicle. This imbalance may cause accidents, such as rollovers or container collapses, posing significant risks to crew members, vehicles, and the cargo itself.

- Maintaining Stability: During sea voyages or overland transportation, vessels and vehicles may encounter rough weather conditions, rough terrain, or sudden movements. Without proper lashing, the cargo may move excessively, jeopardizing the stability of the entire vessel or vehicle.

- Compliance with Regulations: The shipping industry is governed by strict international regulations and guidelines set by organizations such as the International Maritime Organization (IMO) and the International Convention for the Safety of Life at Sea (SOLAS).

- Protecting Valuable Cargo: Many shipments consist of high-value goods, fragile items, or hazardous materials. Proper lashing and securing help protect such cargo from damage during transportation.

- Efficient and Timely Deliveries: Well-secured cargo is less likely to experience delays caused by accidents, inspections, or repackaging.

- Enhancing Supply Chain Reliability: Efficient cargo securing contributes to the overall reliability of the supply chain. When cargo arrives on time and in good condition, it reduces the risk of production delays, inventory shortages, and disruptions in the supply chain.

Types of Container Lashing Solutions

Container lashing methods vary depending on the type of cargo, its weight, and the level of security required during transportation. Selecting the right lashing equipment involves a thorough understanding of the cargo’s characteristics, choosing appropriate lashing materials, and complying with industry standards and regulations.

To make the right choices, several factors need to be taken into account, including the cargo type and weight, the choice of lashing material, and compliance with industry standards and regulations.By prioritizing cargo safety and compliance, shippers can optimize their cargo securing practices, mitigate risks, and ensure the successful and secure transportation of goods. Some common lashing methods include:

- Woven Lashing Belts: Highly durable and versatile, woven lashing belts are widely used due to their strength and ability to withstand tension and pressure.

- Steel Strapping: Ideal for heavy or bulky items, steel strapping provides robust support to secure large and dense cargo.

- Wire Ropes and Cable Lashing: Suitable for irregularly shaped cargo, wire ropes and cable lashing offer flexibility and strength.

- Dunnage Bags: Air-filled dunnage bags are used to fill void spaces and prevent the movement of cargo during transportation.

- Twistlocks and Turnbuckles: Often used in intermodal shipping, twist locks and turnbuckles securely lock containers together on ships and trucks.

Best Practices for Container Lashing

Adopting proper lashing techniques is crucial for cargo safety and the prevention of accidents during transportation. By selecting the appropriate lashing method based on cargo type and shape, and adhering to industry best practices, shippers can ensure the secure and successful transport of goods while mitigating the risks of damage or injury.

Training and Certification

Proper training and certification for lashing personnel are essential in the effective implementation of cargo securing practices. Well-trained personnel are better equipped to handle various cargo types, apply appropriate lashing techniques, and respond to emergency situations.

Proper Lashing Techniques

Implementing proper lashing techniques is essential for the effectiveness of the cargo securing process. The effectiveness of lashing depends not only on the choice of equipment but also on the correct execution of securing methods. Some widely used lashing methods include:

- Cross Lashing Method: The cross lashing method involves forming a secure “X” pattern over the cargo to evenly distribute tension and prevent lateral movement.

- Loop Lashing Method: The loop lashing method involves creating loops around the cargo and connecting them to the container’s internal tie-down points or lashing rings. This technique is useful for securing multiple items or irregularly shaped cargo.

- Diagonal Lashing Method: The diagonal lashing method is suitable for securing cargo with irregular shapes or when using wire ropes or cable lashings. This technique creates diagonal tension to keep the cargo stable.

- X-Pattern Lashing Method: The X-pattern lashing method combines elements of the cross lashing and loop lashing techniques, providing a strong and secure hold on the cargo.

Always ensure that the lashing equipment is in good condition, free from damage, and properly rated for the cargo’s weight and transportation mode. Distribute the tension evenly across the cargo to prevent undue stress on specific points. Use edge protectors or cushioning materials to protect the cargo and prevent damage from lashing pressure.

Regular inspection and maintenance of lashing equipment are also essential to ensure its reliability and safety. Conducting periodic checks, detecting signs of wear and tear, and promptly replacing damaged equipment are crucial steps in preventing potential cargo accidents.

Comply with Industry Standards

Adherence to industry standards and regulations is paramount when selecting lashing equipment. The International Maritime Organization (IMO) and other international bodies have set guidelines to ensure the safety of cargo, vessels, and personnel during shipping. Some key regulations related to cargo securing include:

- IMO Guidelines: The IMO has published guidelines, including the Code of Safe Practice for Cargo Stowage and Securing (CSS Code), which provide detailed recommendations for safe cargo securing practices.

- ISO Standards: The International Organization for Standardization (ISO) has developed standards that specify testing procedures and requirements for various lashing materials, ensuring their quality and performance.

- National and Regional Regulations: Different countries and regions may have specific regulations concerning cargo securing practices that shippers must comply with.

Failure to comply with these regulations can lead to penalties, delays, and potential cargo rejections. Therefore, it is essential for shippers to stay up-to-date with the latest industry standards and ensure their lashing equipment meets the required specifications.

Weather and Environmental Considerations

Lashing practices should account for the impact of weather and environmental conditions on cargo security. Proper protection against corrosion and rust in maritime environments and selecting weather-resistant lashing materials are crucial steps in ensuring cargo safety.

Conclusion

Implementing best practices for container lashing and securing cargo is essential for the safety of goods, personnel, and vessels involved in the shipping process. By understanding cargo requirements, choosing appropriate lashing methods, and adhering to industry standards, companies can optimize cargo safety, reduce risks, and ensure the smooth and secure transport of goods worldwide.

Stream Peak offers a wide range of container lashing and load securing packaging solutions. Our team of packaging engineers provides comprehensive training sessions to ensure your personnel are well-versed in the best practices for cargo securing. Contact us for a demonstration. Ensure safe cargo transit with Stream Peak.