Exploring Different Types of Data Loggers: Applications and Features

Data loggers are essential tools in various industries to collect and monitor information. These devices are crucial in recording data over time, enabling informed decisions and process optimisation. This article focuses on two key types: temperature and humidity data loggers and impact and vibration data loggers. We’ll explore their features, applications, and advancements, highlighting their significance in driving industry insights.

Understanding Data Loggers

Data loggers are compact electronic devices that capture, record, and store data over extended periods. Their primary function revolves around systematically collecting information from various sensors or inputs, ensuring that valuable data points are captured and preserved for later analysis. This functionality is particularly valuable in scenarios where real-time monitoring might not be feasible or necessary.

Data loggers are manufactured with a range of sensors that allow them to measure diverse parameters such as temperature, humidity, pressure, light intensity, voltage, current, and more. These sensors continuously gather data at specific intervals, creating a chronological record that reflects changes and trends over time.

Once configured and set in place, they operate independently, eliminating the need for constant supervision. This makes them highly practical for applications where consistent data collection is vital, such as environmental monitoring, quality control, scientific research, and process optimisation.

The stored data can be retrieved and analysed later, allowing an in-depth examination of patterns, anomalies, and correlations. Additionally, data loggers can often be programmed to trigger alerts or notifications based on predefined thresholds, providing timely warnings when critical conditions are met.

Key Features to Consider

When selecting a data logger for a specific application, it’s important to consider several features in determining its effectiveness and compatibility with the intended use case.

- Sensor Types: The choice of a logger should be based on sensors that accurately capture the specific data points required for the application. For example, temperature and humidity data loggers require accurate and reliable sensors to monitor environmental conditions effectively.

- Memory Capacity: The memory capacity of a data logger dictates how much data it can store before reaching its limit. Depending on the monitoring duration and data collection frequency, a logger with an appropriate memory size is necessary. A sufficient memory could lead to data loss if the logger fills up quickly.

- Battery Life: Long battery life ensures the data logger remains operational without frequent battery replacements or recharging. Battery life can vary significantly depending on the logger’s power consumption and the frequency of data collection.

- Connectivity Options: Data retrieval and analysis are streamlined when data loggers offer various connectivity options. These options, such as USB, Bluetooth, Wi-Fi, and cellular connectivity, enable remote access, real-time monitoring, and easy data transfer to computers or cloud platforms.

- Data Retrieval Methods: While some loggers require a direct connection to a computer for data download, others offer wireless or remote access options, particularly advantageous for hard-to-reach or hazardous environments.

- Data Visualization and Analysis: The software or interface is essential for data analysis. An intuitive and user-friendly software platform simplifies the process of visualising, analysing, and interpreting collected data.

- Durability and Environmental Ratings: Depending on the intended use, the logger might need to withstand harsh environmental conditions, moisture, dust, or physical impacts. Loggers with appropriate durability ratings (IP ratings) and protective casings are preferred.

- Alerts and Notifications: Some recorders can be configured to send alerts or notifications when specific conditions or thresholds are met. This feature is invaluable for immediate response in critical situations, such as detecting temperature spikes or voltage fluctuations.

Temperature and Humidity Data Loggers

Temperature and humidity data loggers help maintain the integrity of products, processes, and environments. By accurately monitoring these vital parameters, they safeguard quality, compliance, and operational efficiency across diverse sectors. They provide accurate and continuous data on these critical environmental parameters, enabling informed decision-making, process optimisation, and regulatory compliance.

Applications: In food storage, they ensure that perishable goods are kept within safe temperature ranges, preventing spoilage and maintaining quality. In the pharmaceutical sector, temperature-sensitive medications and vaccines require controlled storage conditions to preserve efficacy. Moreover, industrial processes, cleanrooms, museums, and HVAC systems rely on temperature and humidity data loggers to maintain optimal conditions.

Sensor Technology: Thermistor sensors, thermocouples, and resistance temperature detectors (RTDs) are commonly used for temperature. These sensors respond to temperature changes and provide reliable readings. On the other hand, Humidity measurements are often facilitated by capacitive or relative humidity sensors. These sensors detect changes in moisture levels and translate them into humidity readings.

Data Analysis: This data reveals patterns, trends, and anomalies crucial for maintaining desired conditions. For instance, deviations from optimal temperature ranges in pharmaceutical storage could lead to compromised medications. In food storage, temperature spikes could indicate equipment malfunctions or power outages, prompting immediate action to prevent product loss.

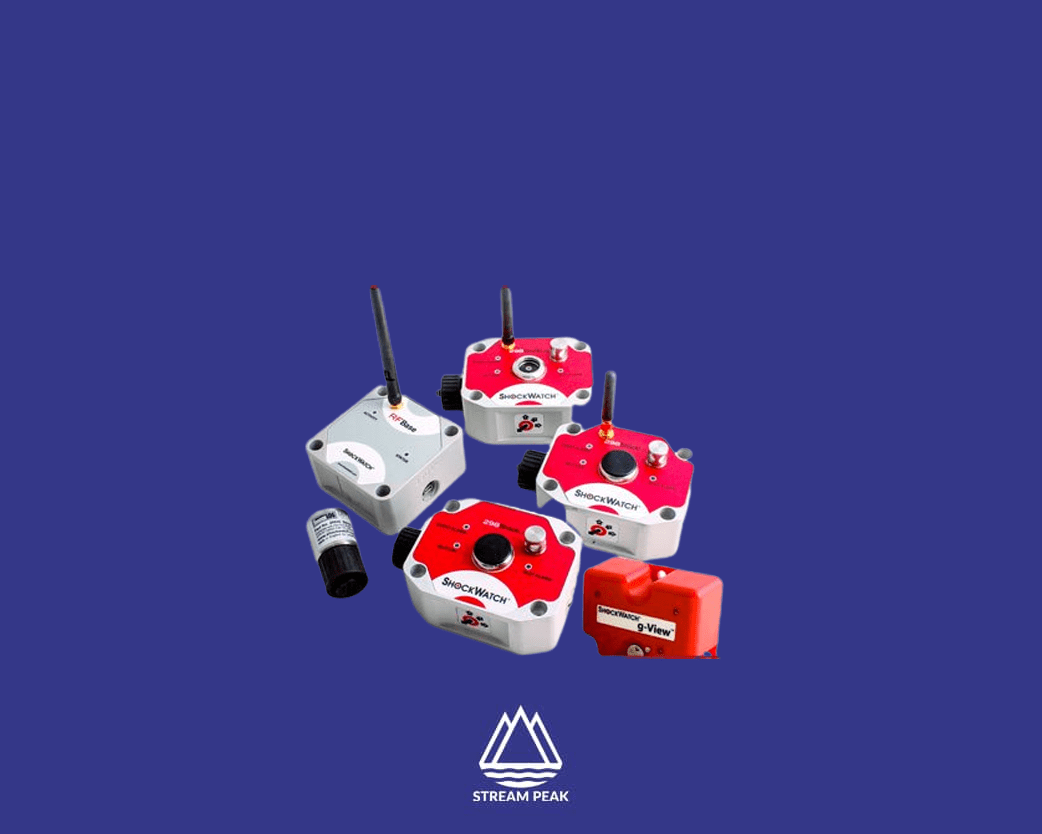

Impact and Vibration Data Loggers

Impact and vibration data loggers improve safety, reliability, and performance across various industries. These loggers play a crucial role in understanding the effects of impacts, vibrations, and shocks on various materials and systems. By providing accurate data on these dynamic forces, impact and vibration data loggers enable engineers, researchers, and industries to make informed decisions regarding safety, performance, and design improvements.

Industrial Applications: During transportation, these loggers assess the stress and strain vehicles endure during transit, helping to optimise packaging and secure goods. In construction, they monitor the impact of heavy machinery on structures to ensure safety and structural integrity. In equipment testing, loggers identify weak points in design, aiding in creating more robust products. Additionally, these loggers find applications in aerospace, energy, automotive, and more.

Sensor Technology: Accelerometers are commonly used sensors that measure changes in acceleration, allowing for the detection of sudden impacts and vibrations. These sensors come in various forms, such as piezoelectric, capacitive, and piezoresistive accelerometers, each tailored for specific measurement ranges and sensitivities.

Data Interpretation: Recorded data provides valuable information about impacts and vibrations’ intensity, duration, and frequency. Engineers analyse this data to evaluate potential damage, assess the effectiveness of damping systems, and fine-tune designs to withstand real-world conditions. By identifying critical stress points, industries can reduce maintenance costs, prevent failures, and enhance product reliability.

Comparative Analysis of Data Loggers

Temperature and humidity data loggers excel in precision environmental monitoring, ensuring compliance and product quality. Their accuracy is essential for industries like pharmaceuticals and food storage. Conversely, impact and vibration data loggers excel in assessing structural integrity and dynamic forces. They find their niche in industries where equipment resilience, such as construction and transportation, is paramount.

Both types of data loggers have distinct cost structures when considering cost factors. Temperature and humidity loggers are often priced based on the precision of measurements, sensor technology, and additional features like wireless connectivity. Impact and vibration loggers, on the other hand, are influenced by the complexity of their accelerometer sensors and the ability to withstand rugged conditions. While the initial investment may vary, the potential long-term costs include maintenance, calibration, and replacement.

Selecting the appropriate data logger hinges on thoroughly understanding specific monitoring needs. Temperature and humidity data loggers are ideal for industries where controlled conditions are critical, offering compliance assurance and product quality control. On the contrary, impact and vibration loggers take centre stage if assessing structural stress, identifying potential damage, or optimising designs is the focus. The choice is influenced by the nature of the data needed, environmental conditions, and the ultimate goal of the monitoring process.

Conclusion

Data loggers are vital tools across industries, enabling data collection for informed decisions, process optimisation, and compliance. Temperature and humidity loggers ensure optimal conditions, while impact and vibration loggers maintain equipment integrity. These devices identify trends and anomalies, reducing costs and improving efficiency.

Stream Peak offers a wide range of data loggers, including temperature and humidity and impact and vibration data loggers. Our range encompasses calibration choices and certified calibration for precise data collection. Connect with our packaging engineers to schedule a no-obligation appointment and learn more about our data logger solutions.