Vibration Monitoring with Vibration Data Loggers

In today’s fast-paced industrial landscape, ensuring the safety and efficiency of machinery and equipment is paramount. Vibration monitoring is crucial in identifying potential faults, preventing breakdowns, and optimizing machine performance.

Traditional manual monitoring methods have limitations, such as the inability to capture continuous data or monitor hard-to-reach locations. However, with the advent of vibration data loggers, industries can improve maintenance practices and reduce downtime. In this blog, we will delve into the benefits and applications of vibration data loggers in modern industrial settings.

Importance of Vibration Monitoring

Vibration monitoring has become an essential aspect of modern industrial practices, serving many purposes crucial for the overall health and performance of machinery and structures. Below are some compelling reasons why vibration monitoring is required:

- Early Fault Detection: Vibration monitoring enables the early detection of mechanical faults, such as misalignments, unbalanced components, and bearing wear. Identifying these issues in their initial stages allows for timely maintenance, preventing major breakdowns and costly repairs.

- Predictive Maintenance: Maintenance teams can adopt a predictive maintenance approach by continuously monitoring vibrations. This data-driven strategy involves scheduling repairs and replacements based on the machine’s condition, maximizing uptime, and minimizing unplanned downtime.

- Improved Safety: Machinery operating outside safe vibration limits poses a safety risk to workers and surrounding infrastructure. Vibration monitoring ensures that equipment operates within safe thresholds, safeguarding personnel and the environment.

- Optimal Performance: Vibration monitoring optimizes the performance of machinery. By maintaining equipment within specified vibration levels, industries can achieve higher productivity, energy efficiency, and extended lifespan.

- Reduced Maintenance Costs: Proactive maintenance based on vibration data allows for targeted repairs and component replacements. This minimizes unnecessary maintenance expenses and extends the life of critical equipment.

- Condition Assessment of Structures: Vibration monitoring is not limited to machines; it also extends to structural health monitoring. Engineers can assess their integrity and identify potential weaknesses or damage by analyzing vibrations in buildings, bridges, and other structures.

- Compliance with Regulations: Certain industries, such as mining and construction, must adhere to strict vibration regulations to minimize the impact on nearby communities and ecosystems. Vibration monitoring helps ensure compliance with these regulations.

- Remote Monitoring: Vibration data loggers enable remote monitoring of machinery and structures in hard-to-reach or hazardous locations. This capability reduces the need for physical inspections, enhancing safety for maintenance personnel.

- Data-Driven Decision-Making: Vibration monitoring provides valuable data that drives informed decision-making. Engineers can use this data to optimize maintenance schedules, allocate resources efficiently, and plan future upgrades.

- Process Optimization: In manufacturing and industrial processes, vibration monitoring helps identify inefficiencies, reduce waste and optimise production lines for higher output and improved product quality.

Understanding Vibration Data Loggers

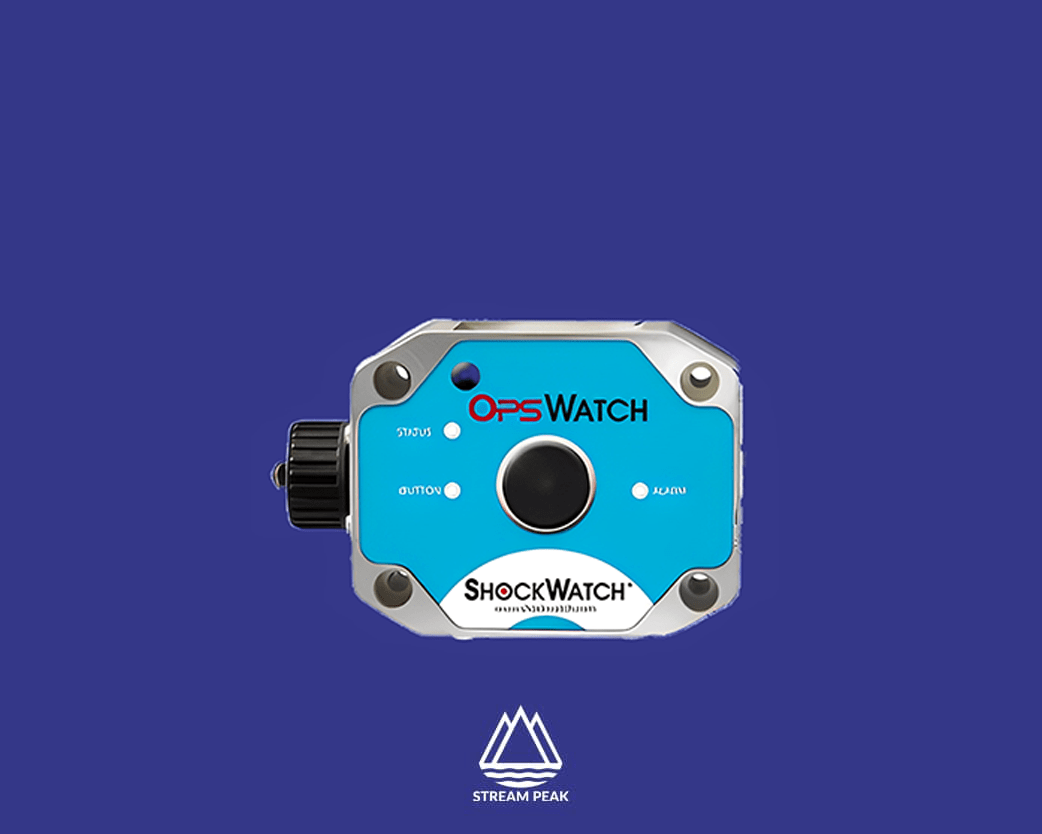

Vibration data loggers are compact, portable devices designed to measure, record, and analyze vibrations in industrial equipment. They consist of accelerometers that detect mechanical vibrations and internal memory to store the data. These loggers offer real-time monitoring capabilities and can be set up to collect data at specific intervals, providing a comprehensive picture of the machine’s health over time.

Benefits of Vibration Loggers

- Condition Monitoring: Vibration data loggers enable continuous machinery monitoring, allowing engineers to detect anomalies and potential faults early on. This proactive approach to maintenance helps prevent costly breakdowns and reduces unplanned downtime.

- Data-Driven Decision Making: By gathering and analyzing vibration data, maintenance teams can make informed decisions regarding repair or replacement, optimizing maintenance schedules and extending the lifespan of equipment.

- Remote Monitoring: Vibration data loggers can be placed in hard-to-reach or hazardous areas, providing valuable data without exposing workers to unnecessary risks. This capability benefits the mining, oil and gas, and construction industries.

- Efficiency and Productivity: Companies can enhance productivity and overall operational efficiency by ensuring that machines operate within safe vibration limits.

- Cost-Effective: Vibration data loggers offer a cost-effective solution for condition monitoring compared to complex online monitoring systems. They are relatively affordable, easy to install, and require minimal maintenance.

Applications of Vibration Data Loggers

- Predictive Maintenance: Vibration data loggers play a central role in predictive maintenance strategies. By continuously monitoring vibrations, maintenance teams can identify wear and tear, misalignments, and imbalances in rotating machinery, predicting when maintenance is required before critical failures occur.

- Fault Diagnosis: When machinery malfunctions, vibration data loggers provide valuable data that can aid in diagnosing the root cause of the issue. This information assists engineers in making accurate repairs and minimizing downtime.

- Structural Health Monitoring: Vibration data loggers can also be used for structural health monitoring of buildings, bridges, and other infrastructure. Engineers can assess structural integrity and detect any potential defects by analysing vibrations.

- Environmental Monitoring: In some cases, vibration data loggers are employed to monitor the impact of industrial activities on the surrounding environment. This ensures that operations comply with regulations and helps minimize disturbances to nearby communities.

Best Practices for Vibration Monitoring

To make the most of vibration data loggers, it is essential to follow some best practices:

- Calibration: Regularly calibrate the vibration data loggers to maintain measurement accuracy and consistency.

- Appropriate Placement: Properly position the loggers on the equipment to ensure accurate data collection. Understanding the machine’s critical components and mounting locations is crucial for effective monitoring.

- Data Analysis: Use specialized software to analyze the collected data. This can help detect patterns, trends, and potential issues that may not be evident from a quick inspection.

- Integration with Maintenance Programs: Integrate the data obtained from vibration data loggers with existing maintenance programs to develop effective and timely maintenance strategies.

Types of Vibration Data Loggers

Vibration data loggers come in various types, each tailored to specific monitoring requirements. Below are some common types of vibration data loggers:

- Single-Axis Loggers: These loggers measure vibrations along one axis, suitable for monitoring machinery with predominantly unidirectional vibrations.

- Triaxial Loggers: Triaxial loggers measure vibrations in three axes (X, Y, and Z), providing a comprehensive view of machinery performance and structural health.

- Wireless Loggers: Wireless data loggers eliminate the need for physical connections, allowing remote monitoring and real-time data access.

- High-Frequency Loggers: Designed to capture high-frequency vibrations, these loggers are ideal for detecting subtle abnormalities in precision equipment.

- Low-Frequency Loggers: These loggers focus on low-frequency vibrations, well-suited for monitoring large structures and heavy machinery.

- Portable Loggers: Compact and battery-operated portable loggers offer flexibility for monitoring and assessing different locations on the go.

- Online Loggers: Online loggers provide continuous monitoring and real-time data streaming for critical applications that demand immediate attention.

- USB Data Loggers: These loggers connect to computers via USB ports, simplifying data transfer and analysis processes.

Conclusion

Vibration data loggers offer numerous benefits to industries worldwide. From predictive maintenance to fault diagnosis and structural health monitoring, these compact devices empower businesses to enhance safety, reduce downtime, and optimize equipment performance. By adopting vibration data loggers into their maintenance routines, industries can improve efficiency and reliability while fostering a safer and more sustainable working environment.