Vibration and Shock Monitoring: Safeguarding Critical Assets

The transportation of special cargo demands a high level of precision and care. Irrespective of the mode of transport—land, air, or sea—avoiding vibrations and shocks entirely proves to be an elusive task. The sensitivity of the cargo to vibrations and shock is frequently a cause for concern.

Unavoidable occurrences, such as bumpy roads during forklift and crane operations, can lead to impactful shocks on the goods transported. Similarly, the continuous vibrations generated by a ship’s engine or the humming of a truck can resonate with the frequency of the components within the cargo, posing potential risks. Moreover, certain equipment is particularly vulnerable and can suffer severe damage when subjected to excessive tilting.

Understanding Vibration and Shock Monitoring

Vibration monitoring quantifies oscillations, oscillatory motions, or vibrations experienced by an object or system. On the other hand, shock monitoring involves measuring and analysing sudden accelerations or decelerations experienced by an object due to impacts or external forces. Both these techniques rely on advanced sensors and monitoring systems to capture and interpret the data generated during the operation of assets.

Monitoring During Transit Operations

Transportation tends to cause vibration and shock in some capacity. Impacts cannot be avoided entirely; all cargo can withstand this up to a certain threshold. When this threshold is crossed, goods can get damaged. For machinery, this can affect its lifespan, its performance and even cause risks to safety.

Measuring the amount of shock and vibrations a piece of equipment goes through is vital. It can be an indicator of whether or not the equipment is damaged. This can cause several problems. High shock levels can be generated on the supply chain, so supply chain impact monitoring is essential.

High shock levels can cause internal displacement of parts and damaged equipment. High levels of vibrations can cause the same. The difference, however, is that vibrations are way harder to prevent than shocks. There are many reasons for this, primarily as it is a natural occurrence because of how vehicles operate. Terrain variability and the transport environment also affect the vibration levels.

Factors that induce vibrations will always exist due to vehicular and environmental conditions. In industrial devices, vibrations alone can cause imbalance, wear and tear, looseness, or misalignment. Hence, the vibrations and shocks must constantly be monitored to avoid damage and losses.

Shock and Vibration Recorders

In the landscape of supply chains, the potential for damage can occur at every stage of the process. However, shock sensors can minimise this risk, ensuring seamless operations. These tools provide timely alerts when a load experiences a sudden and forceful impact. During shipping, transit, or storage, goods are susceptible to significant damage, and shock sensors play a crucial role in detecting and preventing such occurrences.

Shock sensors provide immediate warnings and promptly identify and address issues. By analyzing the data gathered during transporting and storing of goods, companies can pinpoint vulnerable areas in their supply chain, allowing for targeted improvements and optimization. This information proves vital for users to determine if their product has incurred any damage during transit, enabling them to take appropriate actions swiftly.

Benefits of Shock Sensors

The application of shock sensors not only expedites troubleshooting processes but also instils a sense of responsibility and attentiveness among the agents handling the cargo. Armed with real-time feedback, personnel become more diligent in their duties, ensuring that goods are handled carefully.

- Preventive Maintenance: One of the most significant advantages of vibration and shock monitoring is its enabling preventive maintenance strategies. Detecting early signs of wear and tear or abnormal vibrations empowers maintenance teams to plan maintenance activities proactively, reducing unplanned downtime and associated costs.

- Cost Savings: Minimizing downtime and preventing catastrophic failures saves costs and extends the operational life of assets. Predictive maintenance can optimize the replacement of parts and reduce the likelihood of emergency repairs, resulting in substantial financial benefits for businesses.

- Enhanced Safety: Monitoring vibrations and shocks in critical structures and machinery helps ensure the safety of personnel and the public. Addressing potential issues promptly prevents accidents and injuries.

- Improved Performance: Vibration and shock monitoring also contribute to improved asset performance. Operators can fine-tune machinery and equipment by identifying inefficiencies and irregularities for optimal performance and energy efficiency.

- Compliance and Regulations: In some industries, compliance with regulatory standards is crucial. Vibration and shock monitoring help businesses adhere to relevant safety and environmental regulations, avoiding potential legal and financial consequences.

Introducing Monitoring Solutions

Impact sensors use electronic circuits or mechanical systems to monitor, measure and respond to outside forces. Electric circuits are configured such that forces cause a variance in signal level voltages which can be monitored over time to give more accurate data. Mechanical systems can be designed with a threshold that will cause a change in the system, which will be evident to an outside observer.

- Shocklog 248: This monitoring device is available in multiple impact scales and efficiently records impacts and environmental conditions experienced by equipment during transportation or storage. The data can be easily accessed and downloaded through its user-friendly interface or USB. Its tamper-proof system ensures the accuracy and reliability of recorded data.

- Shocklog 298: Building upon the capabilities of its predecessor, Shocklog 298 introduces user-programmable impact scales and frequency filters for enhanced flexibility. Additionally, optional sensors can be incorporated, expanding the device’s capabilities to meet specific monitoring needs.

- Shocklog Cellular: Combining the features of Shocklog 298 with a cellular communication system, this device offers real-time alerts, even in areas lacking satellite visibility. It has an impressive battery life of over 90 days and ensures consistent updates on any changes. It provides a comprehensive impact and temperature data log, tri-axial impact, and tracking capabilities.

- Shocklog Satellite: This device integrates Shocklog 298’s functionalities with a satellite communication module to deliver real-time reports and asset location details. Users receive periodic reports every four hours, providing crucial insights into mishandling incidents.

- Shocklog g-View: A precise data logger, Shocklog g-View captures and records data for more than 100 threshold events per axis, complete with accurate time and date stamps. The device promptly sends alerts when potentially damaging impacts are detected, enabling timely responses from handlers.

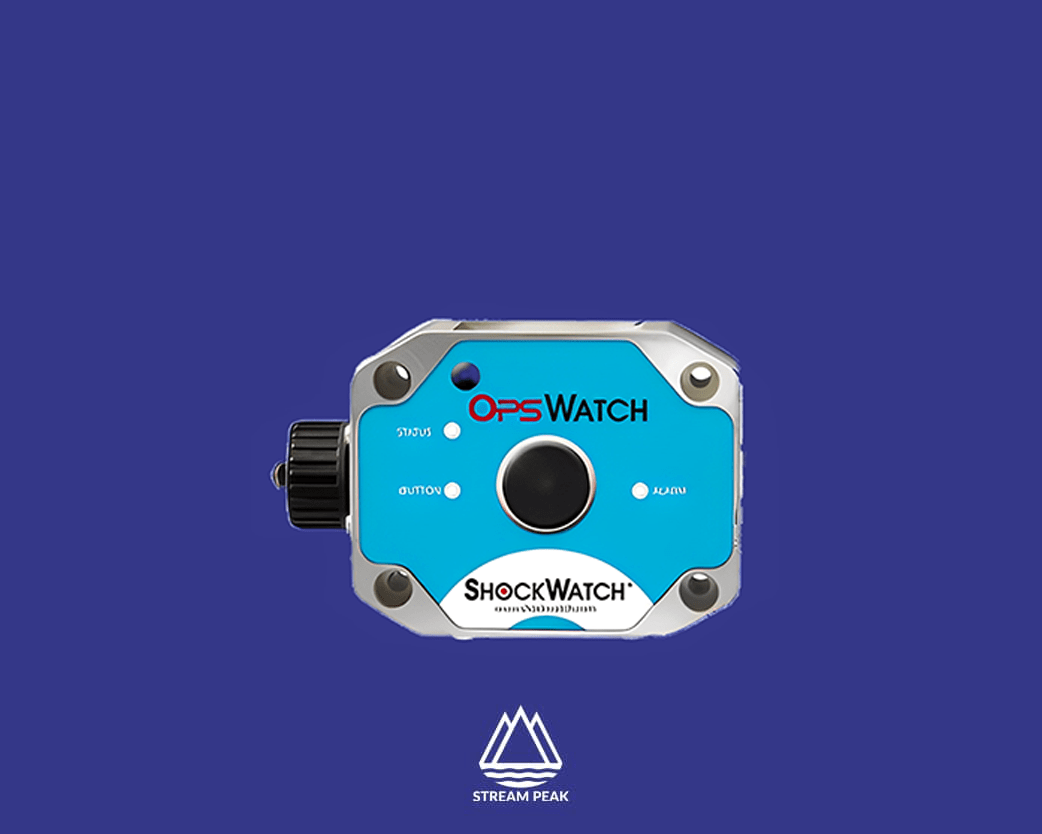

- OpsWatch: A Wi-Fi-enabled vibration and impact monitoring system, OpsWatch continually gathers and analyzes data to identify deviations beyond normal parameters. Through its online web-hosted platform and Wi-Fi communication, it ensures real-time alerts are delivered to users for proactive intervention.

Applications of Vibration and Shock Monitoring

Vibration and shock monitoring find various applications across various industries because they ensure critical assets’ safety, reliability, and efficiency. Let’s delve into some key areas where these monitoring techniques can be employed:

- Industrial Machinery and Equipment: Vibration and shock monitoring plays a pivotal role in ensuring the health and longevity of industrial machinery and equipment. Monitoring rotating machinery, such as pumps, motors, turbines, and compressors, allows for early detection of potential issues such as misalignment, unbalance, bearing wear, and mechanical looseness. Identifying these problems in their early stages empowers maintenance teams to plan and execute corrective measures, thereby averting costly breakdowns and downtime.

- Structural Health Monitoring (SHM): In civil engineering and infrastructure projects, SHM employs vibration monitoring to assess the structural integrity of buildings, bridges, dams, and other critical structures. Continuous monitoring assists in detecting any anomalies or damages caused by environmental factors, excessive loads, or natural disasters, enabling timely repairs and preventing catastrophic failures.

- Aerospace and Defense: In the aerospace and defence industries, vibration and shock monitoring are critical for evaluating the health of aircraft, satellites, and missiles. Monitoring the performance of critical components and avionics ensures safe operations and enhances the longevity of these high-value assets.

- Transportation and Automotive: Vibration and shock monitoring find applications in the transportation sector, enabling the safe and efficient operation of trains, ships, and automobiles. Monitoring rail tracks, wheels, and engines aids in optimizing maintenance schedules, ensuring passenger safety, and minimizing disruptions in transportation services.

Conclusion

Overall, the transformative benefits of vibration and shock monitoring extend beyond preventing damage; they empower businesses to implement proactive maintenance strategies, optimize performance, and prioritize the safety of both assets and personnel.

As technology advances, integrating artificial intelligence and machine learning with vibration and shock monitoring promises even more precise predictive capabilities, further revolutionizing asset management and safety practices across industries.