Complete Guide to Molecular Sieves Desiccants

Molecular sieves desiccants are versatile and efficient agents critical in various industries. Their exceptional moisture-absorbing properties make them useful in applications ranging from pharmaceuticals and electronics to industrial processes and packaging. In this article, we will share more on molecular sieves desiccants, exploring their composition, working principles, diverse applications, and the environmental impact they make.

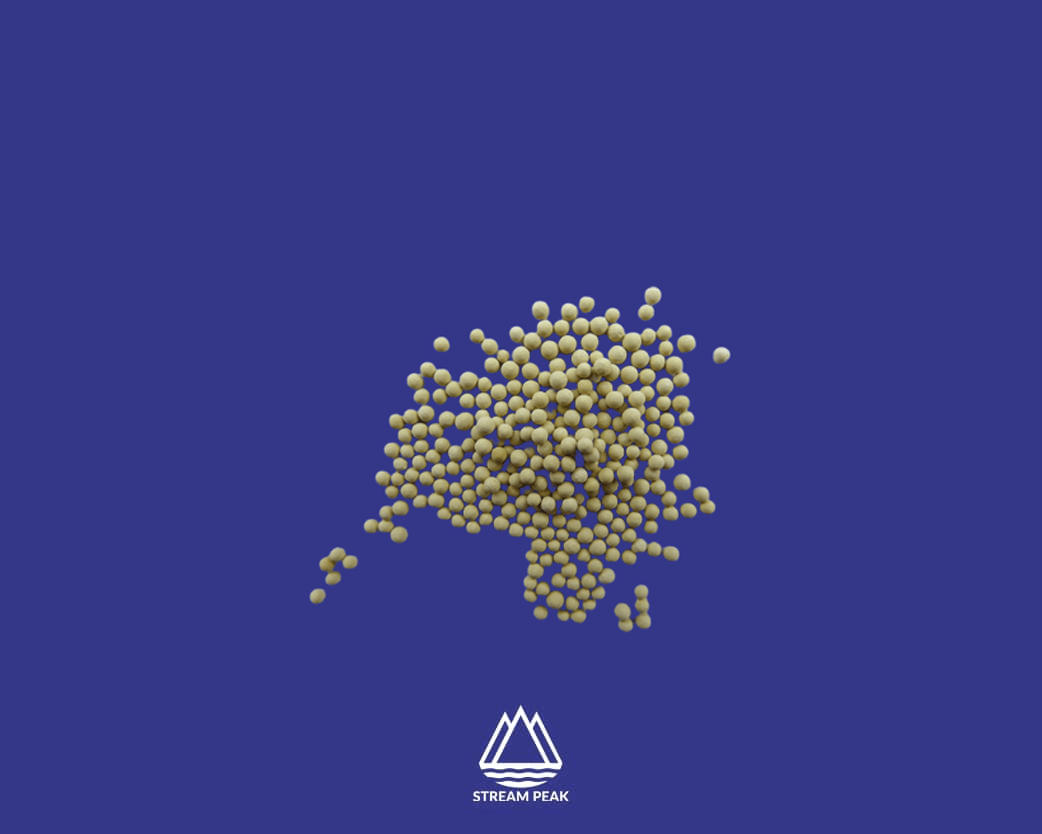

Understanding Molecular Sieves Desiccants

Molecular sieves are crystalline substances composed of three-dimensional frameworks with regularly spaced pores of precise dimensions. These nanometer-sized pores create a network that acts as a molecular filter, permitting only certain molecules to pass through based on their size and shape.

The composition of molecular sieves varies, but they are commonly based on crystalline aluminosilicates known as zeolites. These zeolites are synthetic or naturally occurring minerals with well-defined pore sizes and high surface areas, making them ideal for moisture control applications.

The desiccants can maintain low humidity and prevent moisture-related issues. Their high adsorption capacity, selective adsorption properties, and reusability make them suitable for industries involving moisture-sensitive materials and equipment.

In the packaging and storing of goods, molecular sieves desiccants safeguard against product spoilage, preserving freshness and extending shelf life. Industrial processes protect sensitive machinery and components from corrosion and degradation caused by excess moisture. Moreover, these desiccants contribute to product stability and reliability in pharmaceutical and electronics manufacturing, preventing damage from moisture-induced reactions.

Properties and Adsorption

The key characteristic of molecular sieves is their uniformity in pore size, which enables them to achieve unparalleled selectivity in adsorption processes. The exceptional adsorption properties of molecular sieves stem from their well-defined pore structures and high surface areas as gases or liquids come into contact with the molecular sieve, molecules smaller than the pore size diffuse into the pores, while larger molecules are excluded.

The adsorption mechanism relies on several factors, such as pore size, surface polarity, and the strength of the interactions between the adsorbate molecules and the sieve’s internal surfaces. The strong forces of attraction, such as van der Waals forces and hydrogen bonding, facilitate the adsorption of water and other polar molecules onto the surface of the molecular sieve.

Due to their precise adsorption capabilities, molecular sieves can be tailored for specific applications, selectively adsorbing target molecules while leaving other components untouched. This property is particularly advantageous in desiccant applications, where moisture must be removed without affecting the composition of gases or liquids.

Benefits of Molecular Sieves Desiccants

Molecular sieves desiccants offer many advantages making them a preferred choice in moisture control applications. In this section, we explore their high adsorption capacity, selective adsorption capabilities, and the ability to be regenerated and reused.

1. High Adsorption Capacity

One of the most significant advantages of molecular sieves desiccants is their impressive adsorption capacity. These desiccants can adsorb moisture up to 20% of their weight, far surpassing the adsorption capacity of traditional desiccants like silica gel, which typically adsorb only 10-15% of their weight in water. This high adsorption efficiency means that smaller molecular sieves can achieve the same moisture control results as larger quantities of other desiccants, resulting in cost savings and reduced waste.

The high adsorption capacity of molecular sieves also translates to prolonged service life, as they can effectively maintain low humidity levels for extended periods before requiring regeneration or replacement. This attribute is particularly beneficial in industrial settings where continuous moisture control is crucial for optimal product quality and equipment performance.

2. Selective Adsorption

Molecular sieves desiccants excel in selective adsorption, meaning they can target specific molecules while sparing others. Their uniform and precisely engineered pore structures allow them to discriminate between different molecules based on size and shape. This unique property makes them ideal for applications where only certain substances must be removed, leaving the overall composition of gases or liquids unaffected.

For instance, in the natural gas industry, molecular sieves desiccants can remove water and other impurities while leaving methane and other valuable components intact. Similarly, pharmaceutical manufacturing can adsorb moisture without affecting the stability and integrity of the drugs. Selective adsorption ensures product purity, reduces product loss, and minimises the risk of cross-contamination in various processes.

3. Regeneration and Reusability

Molecular sieves desiccants are regenerable and reusable. Regeneration involves heating the desiccant to release the adsorbed moisture, restoring its adsorption capacity to near-original levels. This highly efficient regeneration process can be repeated multiple times without significantly compromising the desiccant’s performance.

The ability to regenerate and reuse molecular sieves desiccants translates into substantial cost savings and reduced environmental impact. It minimises the need for frequent replacement and disposal, making them a more sustainable choice for moisture control applications.

Types of Molecular Sieves

Molecular sieves are available in various types, each with specific pore sizes and adsorption capabilities tailored for distinct applications. The diversity of molecular sieve types allows industries to select the most suitable desiccant based on their unique moisture control needs.

Each type offers distinct pore sizes and adsorption capabilities, enabling selective removal of target molecules while preserving the integrity of other components. From dehydration in natural gas and petrochemical processes to moisture control in air conditioning and electronics manufacturing, molecular sieves are versatile and indispensable for moisture management across various industries.

- Zeolite 3A: Zeolite 3A is a widely used molecular sieve with a pore size of approximately 3 angstroms. Its exceptional affinity for water molecules makes it an ideal choice for moisture removal in various applications. Zeolite 3A can efficiently adsorb water vapour and other small polar molecules, leaving larger molecules unaffected. Industries utilise this type of molecular sieve in producing dry air, natural gas drying, and dehydration of ethanol, preventing water-induced corrosion and preserving product integrity.

- Zeolite 4A: Zeolite 4A boasts a slightly larger pore size of around 4 angstroms. It can remarkably adsorb water, carbon dioxide, and other small molecules. Due to its efficiency in removing moisture, Zeolite 4A has applications in refrigerant drying, air conditioning systems, and natural gas purification. Removing water and carbon dioxide from these systems enhances their performance and operational life.

- Zeolite 13X: With a pore size of approximately 10 angstroms, Zeolite 13X can adsorb larger molecules, including hydrocarbons and nitrogen compounds. This molecular sieve type is commonly used in air separation processes, removing impurities from liquid and gas streams, and drying petrochemical and industrial gases. Its versatility in adsorbing a wide range of molecules makes it a valuable desiccant in various industries.

- Zeolite 5A and 10A: Zeolite 5A and 10A have intermediate pore sizes of 5 and 10 angstroms, respectively. These molecular sieves find applications in separating gases and liquids, such as removing carbon dioxide and water from the air. They are also utilised to purify liquids and gases in the petrochemical industry. Their ability to target specific molecules within a certain size range makes them valuable tools in selective adsorption processes.

Factors to Consider in Choosing

- Moisture Level Requirements: Assess the specific moisture level requirements of your application. Different molecular sieve types have varying adsorption capacities and are suitable for different moisture control needs. Consider the target humidity level and the volume of moisture to be adsorbed when selecting the appropriate desiccant.

- Pore Size: Molecular sieves desiccants are available in various pore sizes, ranging from 3 to 10 angstroms. Choose a desiccant with a pore size that matches the size of the moisture molecules you need to remove. This ensures optimal adsorption and prevents unnecessary depletion of the desiccant’s capacity.

- Chemical Compatibility: Consider the compatibility of the desiccant with the materials it will come into contact with. Some molecular sieves may react with certain substances or release impurities, which could impact the product’s or equipment’s integrity. Ensure that the selected desiccant does not introduce unwanted interactions in your application.

- Temperature and Pressure Conditions: Evaluate the application’s operating temperature and pressure conditions. Different molecular sieve desiccants have varying stability and performance under different temperature and pressure ranges. Choose a desiccant that can withstand the conditions it will be exposed to without losing effectiveness.

Proper Handling and Packaging

Proper handling and packaging are essential to ensure the efficacy of molecular sieves desiccants. Store molecular sieves desiccants in a dry and cool environment, away from direct sunlight and sources of moisture. High humidity or water exposure can prematurely activate the desiccant, reducing its adsorption capacity.

Keep the desiccant in sealed containers or bags until used. This prevents unnecessary exposure to air and humidity, maintaining its adsorption capabilities. Ensure the desiccant remains free from contaminants and foreign particles during storage and use. Contaminants can interfere with the desiccant’s adsorption process and compromise its efficiency.

Conclusion

Molecular sieves are remarkable solutions characterised by their uniform pore structures, which enable them to act as selective filters for adsorbing specific molecules based on their sizes and shapes. The diverse types of molecular sieves offer a wide range of applications, making them indispensable tools in various industries, particularly desiccants in moisture control processes.

At Stream Peak, we offer quality molecular sieves, undergoing daily in-house quality checks. Stream Peak manufactures molecular sieves desiccant bags in Singapore with ISO 9001 and ISO 14001 certifications, ensuring excellent performance and environmental responsibility. Feel free to contact us for moisture control solutions.