FAQ about Volatile Corrosion Inhibitors (VCIs)

Businesses that package and transport materials from one location to another should use protective packaging. To maintain a product in excellent condition, it must be protected from moisture and other corrosion-causing impurities. Metals, particularly iron, are susceptible to corrosion because of excessive moisture exposure. VCIs are chemical substances that prevent corrosion inside a container. They are highly effective for ferrous and non-ferrous metals.

Frequently Asked Questions about VCI

Corrosion is a significant threat to metal across industries. Volatile Corrosion Inhibitors (VCIs) offer protection. This FAQ guide answers essential questions about VCIs and insights, fundamentals, applications, and intricacies.

1. What Are Volatile Corrosion Inhibitors (VCIs)?

Volatile Corrosion Inhibitors (VCIs) are chemical compounds that protect metals and alloys from corrosion. They release vapor-phase molecules into the surrounding environment, creating a protective layer on the metal’s surface. This layer inhibits or slows down the corrosion process by preventing corrosive elements, such as moisture and oxygen, from coming into contact with the metal.

2. How does VCI work?

Volatile Corrosion Inhibitors (VCIs) use a unique mechanism to protect metal surfaces from corrosion. VCIs work by evaporating and vaporising into a protective vapour that adsorbs onto metal surfaces, forming a barrier that prevents corrosive elements from coming into contact with the metal. This mechanism effectively inhibits corrosion and is particularly useful for preserving metal components during storage and transportation.

3. What are the Different types of VCI?

Volatile Corrosion Inhibitors (VCIs) come in various types, each designed to address specific corrosion prevention needs and compatibility with different metals and environments. Here are some common types:

- VCI Paper: Available for applications that require metal products to be wrapped or layered inside a container. The paper is coated with VCI on both sides, providing all-around protection.

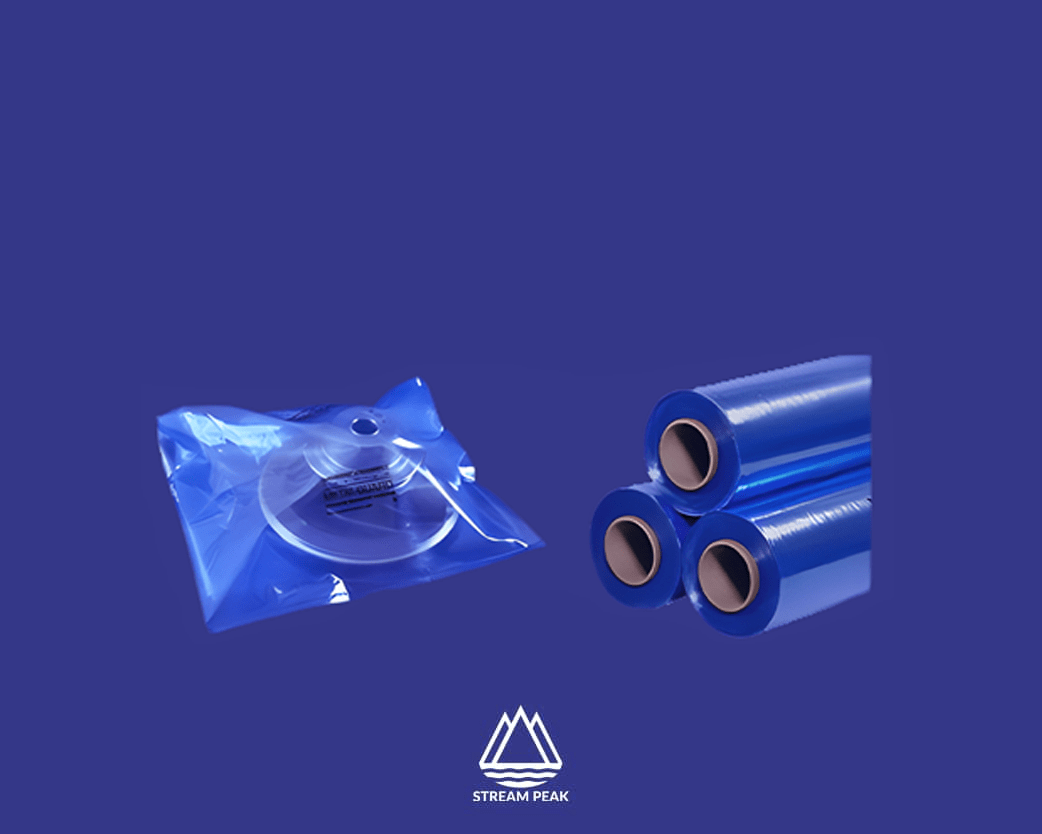

- VCI Film: Ideal for more oversized items and equipment. They are available in film rolls that unwind and reveal a plastic film that uses vapour corrosion inhibitors to coat and protect metal surfaces from corrosion.

- VCI Liquid: Once the VCIs have adsorbed on the surface of the metal, they form a hydrophobic barrier that prevents moisture from penetrating the metal

- VCI Emitter: Lightweight, slim, and compact disks containing corrosion that allow accessibility into tight and restricted spaces to provide rust protection

- VCI Bags: Coated completely with VCI compounds that serve as barriers between the metal and the corrosive substance. Ideal for assembly and packaging lines

- VCI Powder: Lay-up, preservation, and mothball applications protect the void areas of interior cavities. Applied by dusting, fogging enclosures with a low-pressure air hose or as a solution

4. What are the Shelf Life of VCI Products?

The shelf life of Volatile Corrosion Inhibitor (VCI) products can vary depending on several factors, including the type of VCI, the specific formulation, packaging, and storage conditions. VCI products, such as VCI paper, film, emitters, or coatings, typically have a reasonably long shelf life when sealed in their original packaging and remain unopened. Depending on the manufacturer and product specifications, this shelf life can range from one to five years.

5. What are Ferrous and Non-Ferrous Metals?

Ferrous and non-ferrous metals are two broad categories used to classify metals based on their iron content. The key distinction between them is the presence or absence of iron. Ferrous metals contain iron as the primary metal, typically constituting more than 50% of their composition. Non-ferrous metals do not contain significant amounts of iron in their composition.

- Ferrous: Iron, steel, and cast iron metals

- Non-Ferrous: Aluminium (and aluminium alloys containing copper or manganese), copper, brass, bronze, and fully galvanised steel

- Multi-Metal: Products that contain combinations of Ferrous and Non-Ferrous metals

6. Is VCI Film better than VCI Paper?

Whether VCI film or VCI paper is better depends on the specific application and requirements. Both VCI film and VCI paper are tools for protecting metal components from corrosion during storage and transportation, but they have distinct characteristics and advantages.

VCI film offers durability and moisture resistance, making it suitable for challenging environments and applications where mechanical protection is essential. On the other hand, VCI paper is more pliable, cost-effective, and environmentally friendly, making it a practical choice for applications that prioritise flexibility, sustainability, and cost-efficiency.

7. Will VCI be affected by Enclosures that are not Entirely Sealed?

Volatile Corrosion Inhibitors (VCIs) can still be effective even if the enclosures containing the protected metal components are not entirely sealed. However, the level of effectiveness may be influenced by the degree of enclosure sealing and the rate at which the VCI molecules can be released and replenished.

VCIs can still provide corrosion protection in enclosures that are not entirely sealed. Still, the effectiveness may be influenced by factors such as the degree of sealing, ventilation, enclosure size, and duration of storage. It’s important to assess the specific conditions of the application and consider factors that may affect the dispersion and retention of VCIs in the enclosure. Regular monitoring and maintenance can help maintain adequate protection over time.

8. Can VCI Products be Reused?

Volatile Corrosion Inhibitor (VCI) products are typically designed for one-time use, and their effectiveness diminishes over time as the VCI is released into the environment to protect metal surfaces. It’s important to note that the decision to reuse VCI products should be made cautiously and with an understanding of their limitations.

The effectiveness of VCIs can diminish with environmental exposure, and relying on partially depleted VCIs may result in inadequate corrosion protection. In critical applications where metal preservation is essential, fresh VCI products are often recommended to ensure reliable and consistent corrosion prevention.

9. How to Seal Products with VCI?

A tightly sealed VCI packaging yields better volatile corrosion protection. Seal closed with zip-ties, packaging tape, or staples. A good closure is to fold over the film and either tape or staple the area shut. The best seal is always a heat seal. Water must be prevented from entering the packaging.

- Wrap individual metal parts, components, or equipment using VCI Paper

- Before placing the metal parts in a shipping container, line the bottom of the crate with VCI Film or Poly Bags

- Place a layer of parts wrapped in VCI Paper in the crate

- Before adding a new layer, interleave VCI Paper on top of the first layer

- If a wooden crate is used as a base or a pallet is used to brace the packaging environment, it is vital to wrap or cover any wood areas to prevent acidic moisture from contacting metal surfaces

- If corrugated cardboard separators are used between metal parts, be sure to interleave VCI Paper between the cardboard and the metal parts, as these separators can be a significant source of corrosion

10. How long can parts remain corrosion-free after removal of the VCI Package?

The duration for which metal parts remain corrosion-free after removal from a Volatile Corrosion Inhibitor (VCI) package depends on several factors, including the type of VCI used, the environmental conditions to which the parts are exposed, and the specific metal materials involved. To maximise the post-removal corrosion protection, it’s advisable to:

- Store the parts in a clean, dry, and controlled environment.

- Keep humidity levels low, if possible.

- Monitor the condition of the parts regularly.

- Consider using additional corrosion prevention methods if prolonged protection is required.

- Consult the manufacturer’s recommendations for the specific VCI product used.

11. What is the Difference between VCI and desiccants in Preventing Corrosion?

VCI products and Desiccants prevent corrosion in different ways. VCI products prevent corrosion by an electrochemical process that forms a thin molecular layer of protection on a metal surface. This layer of protection is microscopic and does not alter the metal. A desiccant is merely a moisture absorber. Desiccants absorb moisture but do not satisfactorily protect a metal surface from other electrolytes that cause corrosion, such as oxygen. However, using both VCI and Desiccants is also possible.

12. Do Hot or Cold Temperatures Affect VCI Products?

Both hot and cold temperatures can impact VCI products, but the specific effects can vary depending on the type of VCI, its formulation, and the duration of exposure. Manufacturers typically provide guidelines regarding the temperature range within which their VCI products can be stored and used effectively. It’s crucial to adhere to these guidelines and consider the temperature conditions of your storage or transportation environment to optimise the corrosion prevention provided by VCI products.

13. How does a volatile corrosion inhibitor prevent rust and corrosion?

Volatile corrosion inhibitor (VCI) prevents rust and corrosion by acting as a protective barrier from external corrosive atmospheric elements such as abrasion, water, dirt, and acid gas pollutants. It also emits a corrosion-inhibiting vapour that passivates the electron flow between the metal surface’s anodic and cathodic areas. It adds water-repulsion properties that inhibit water from permeating the metal surface and provide the electrolyte for corrosion reactions.

14. How long does the protective layer formed by VCI products last?

The protective layer formed by VCI products will remain on the surface of the metal if there is no significant, continuous exchange of air within the enclosure. Ideally, there should be less than one air exchange per day (for example, when an electrical cabinet or package is opened briefly and occasionally). Once the metal part is removed from the enclosure, the corrosion-inhibiting layer dissipates from metal surfaces within about an hour, leaving the metal part clean, dry, and corrosion-free.

15. What are some examples of VCI products and their applications?

Examples of VCI products include Non-ferrous VCI Film for cost-effective and versatile protection against corrosion damage for non-ferrous metals such as aluminium, copper, brass, bronze, and galvanised steel in shipping and storage, Vapor Capsules for portable VCI protection of electronics and electrical components, VCI bags can be used for temporary VCI protection of ferrous metals during shipment, storage, or work-in-progress, and VCI Kraft Paper for bio-based and biodegradable protection of ferrous, non-ferrous, and multimetal parts.

16. Why are VCI products more efficient and cost-effective than traditional rust prevention methods?

VCI products offer corrosion protection without having to be in direct contact with or coated onto the parts that are being protected. Metal parts must be enclosed in or with a VCI product (where airflow is minimised) for protection to occur. With VCI packaging, it is no longer necessary to apply messy oils, greases, and other corrosion protection compounds and incur the cost of their removal.

Where to buy Volatile Corrosion Inhibitors?

Stream Peak is a company that specialises in providing innovative packaging solutions, including a wide range of Volatile Corrosion Inhibitors (VCI) designed to protect metal components and products from corrosion. Stream Peak’s VCI solutions are designed to offer practical and reliable corrosion protection for your metal components and products.

By following these steps and leveraging the resources on the website, you can make informed decisions when purchasing VCIs, ensuring that your metal assets remain corrosion-free and well-preserved. Contact our packaging engineers to learn more about VCI products and services, including detailed specifications and application guidelines.