What are Volatile Corrosion Inhibitors?

Corrosion in metal parts is typically caused by a chemical reaction between the metal and its environment. This reaction often occurs when metal is exposed to air, moisture, or other corrosive substances. In the presence of oxygen and water, metal surfaces can oxidise, forming metal oxide or hydroxide.

This process can cause the metal to weaken, lose its structural integrity, and ultimately fail. Other factors contributing to corrosion include exposure to salt or chemicals, high temperatures, and mechanical stress. Corrosion can occur in metals like steel, iron, aluminium, and copper.

Preserving Corrosion Prevention

Preventing corrosion is essential for maintaining the integrity and longevity of metal assets in various industries. Corrosion can lead to significant financial losses, safety risks, and compromised performance of equipment and structures. Employing effective corrosion prevention strategies can help mitigate these risks and ensure the durability of metal components. Here are some key methods to prevent corrosion:

- Protective Coatings: A protective coating, such as paint, oil, or wax, forms a barrier against moisture and air, effectively inhibiting corrosion on metal surfaces.

- Galvanization: Galvanization involves coating the metal with a layer of zinc, sacrificially protecting the underlying metal by corroding first.

- Alloying: Enhancing corrosion resistance by adding small amounts of other metals to the base metal.

- Cathodic Protection: Using electrical currents to safeguard metal from corrosion, commonly employed for submerged metal structures and pipelines.

- Environmental Control: Managing the metal’s environment through humidity, temperature, and exposure control, mitigating corrosion risks, especially in corrosive substances like salt.

- Volatile Corrosion Inhibitors: This anti-rust solution forms a thin molecular layer, preventing air and moisture from contacting the metal surface and inhibiting corrosion.

What is a Volatile Corrosion Inhibitor?

VCI stands for Volatile Corrosion Inhibitor. It is a type of corrosion inhibitor that releases molecules with sufficient vapour pressure to form a protective layer on the surface of the metal, effectively inhibiting corrosion on the surface by preventing air and moisture from coming in contact with the surface.

Unlike other corrosion prevention methods, corrosion-inhibiting vapours can reach into intricate surfaces that would otherwise be hard to contact with the traditionally used rust prevention products.

When the anti-rust solution is in contact with metal, it evaporates and forms a molecular layer on the surface of the metal. This layer acts as a barrier, preventing air and moisture from coming into contact with the metal surface, thereby inhibiting corrosion.

The anti-rust solution is commonly used to protect metal components and structures during storage, transportation, and export. They are also useful in protecting complex, hard-to-reach, and sensitive surfaces where other methods, such as coatings or cathodic protection, may be difficult or impractical. The anti-rust solution can be applied as a coating, packaging, or added directly to a fluid or lubricant to protect against corrosion.

Types of Anti-rust Solutions

Metal parts come in diverse shapes, sizes, and weights, necessitating effective corrosion protection. Antirust packaging technology offers versatile solutions in various forms, including paper, foam, packaging film, emitters, powders, tablets, and liquids. These options cater to different applications and ensure comprehensive corrosion prevention for valuable metal assets.

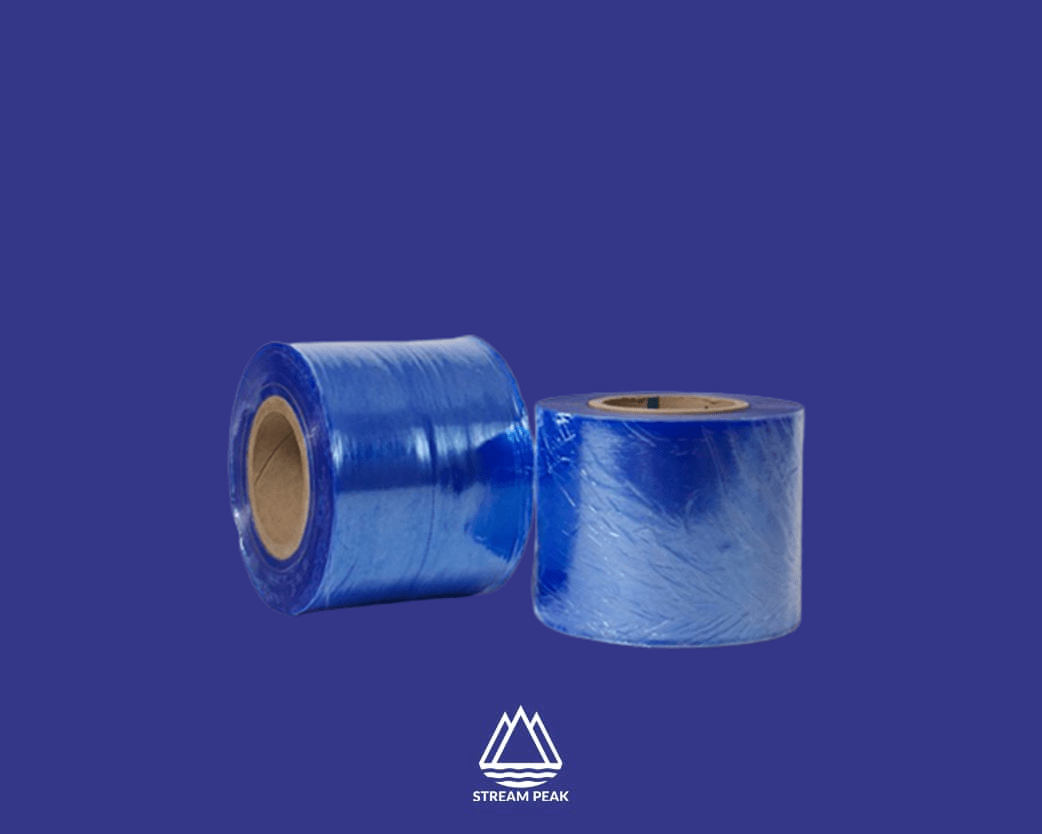

- Packaging Film: These VCI films are versatile and can be used to wrap metal items, providing a protective layer. Volatile corrosion inhibitor films, including large machines, offer reliable protection for various items during storage and transportation.

- Packaging Foam: Available in different sizes, VCI foams are often used with films to provide additional cushioning and protection. They are commonly placed within electrical cabinets and containers to safeguard sensitive components.

- Packaging Paper: Anti-rust paper serves multiple purposes, from wrapping metal parts to creating layers between elements. It is frequently used within wooden crates or boxes to prevent corrosion during shipment.

- Packaging Emitters: Emitters are strategically placed in closed cabinets to protect electrical parts and components from corrosion, ensuring their functionality and longevity.

- Powders: VCI powders are suitable for closed systems, such as water systems, and are ideal for protecting tanks and vessels from corrosion.

- Tablets: VCI powders are suitable for use in closed systems, such as water systems, and are ideal for protecting tanks and vessels from corrosion.

- Liquids: Anti-rust liquids are highly effective in preventing corrosion and play a significant role in preserving the integrity of metal surfaces over an extended period.

Using a combination of 2 or more packaging methods can be very useful for combating corrosion. Find out more about VIC paper vs VCI films.

Benefits of using VCI

Volatile corrosion inhibitor packaging is essential for manufacturers because it helps prevent metal parts from corroding during shipping. Avoiding corrosion is critical for manufacturers, as failing to deliver rust-free products to their customers can lead to lost business. Therefore, anti-rust technology is necessary to ensure the quality of products and maintain product damage.

By using anti-rust packaging, manufacturers can prevent losing business due to corrosion. Metal parts are susceptible to rust, which can occur quickly and lead to expensive damage or even render the part unusable. Volatile corrosion inhibitor packaging is a highly effective way to prevent corrosion and can keep metal parts rust-free for up to three years.

Certain packaging methods can even completely lock out moisture, providing the highest level of protection. Wrapping parts with anti-rust packaging before shipping is a much better option than risking the parts rusting during transportation.

General steps for using VCI

Using Volatile Corrosion Inhibitors (VCIs) effectively involves following general steps to ensure optimal corrosion protection for metal assets. While specific applications may have unique requirements, the following general steps provide a guideline for the proper utilization of VCIs:

- Clean the metal surface: Ensure the metal parts are clean and free of dirt, oil, or moisture before applying.

- Select the appropriate method: Choose the volatile corrosion inhibitor packaging method that suits the application, such as volatile corrosion inhibitor paper, foam, packaging film, emitters, powders, tablets, or liquids.

- Apply the packaging: Following the manufacturer’s instructions, apply the packaging method. For instance, paper is commonly used to wrap individual components, while foam can protect entire assemblies.

- Seal the packaging: Ensure that the packaging is sealed tightly to prevent air and moisture from coming in contact with the metal surface.

- Store the metal parts: Store the metal parts in a dry and cool place, away from direct sunlight, to maximise the effectiveness of the packaging.

Following these steps, effectively use volatile corrosion inhibitors to prevent corrosion in metal parts during storage and shipping.

Conclusion

Volatile corrosion inhibitors are a highly effective packaging method for preventing corrosion, offering a long-lasting solution against rust. Its benefits are particularly useful for manufacturers who need to ship metal components and prevent rust and other forms of corrosion.

Anti-rust protection can help businesses maintain their reputation and prevent lost sales due to damaged products. It is truly an incredible advancement in technology, providing a cost-effective and efficient solution for corrosion prevention. Find out more about the FAQ of VCI, and here is a video about Volatile Corrosion Inhibitors (VCI).