Types of Desiccants

A desiccant is a material that absorbs and removes moisture from the air and is commonly used to control humidity levels in an environment, protecting against water damage. The absorbers are most commonly found in the form of small packets or canisters, which are placed inside sealed containers to protect products from moisture damage.

The type of desiccant chosen depends on factors such as humidity levels, adsorption rate and cost. For example, while silica gel is relatively inexpensive and has a high adsorption capacity, it may not be suitable for extremely low humidity levels requirements.

What are the benefits of desiccants?

Moisture control is critical during manufacturing, production, and transportation to maintain low Relative Humidity (RH) inside packaging such as moisture barrier bags or containers. Desiccants are mainly used by food, pharmaceutical, and packaging manufacturers to prevent moisture from entering and extend their products’ shelf-life.

Controlling moisture levels, these absorbers can reduce risks associated with water vapour to protect goods against corrosion or spoilage in storage facilities and transportation systems. Desiccants do not require energy sources or maintenance costs, and their small size makes them easy to transport and store with minimal space.

Shelf Life for Desiccants

The shelf life of a desiccant can vary depending on factors such as type and quality but generally ranges from 6-12 months. For optimal performance, it is recommended that users replace desiccants when they reach half of their original capacity or at least every 12 months, whichever comes first.

Desiccants should be stored in cool, dry conditions away from direct sunlight for maximum efficiency. Humidity indicator cards can be used to monitor humidity ranges within sealed containers, which change colour when exposed to moisture and alert users when their desiccant needs replacing.

Types of desiccants

Desiccants come in a wide variety of types, each with its unique properties and advantages. Common desiccants include silica gel, molecular sieves, calcium chloride, activated alumina, activated clay and carbon. These desiccants all have a strong affinity with water molecules and adsorption capacity depending on the type and quality of the material.

Silica Gel

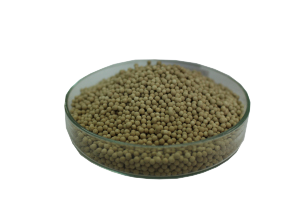

Silica gel is made from silicon dioxide or silica and is an excellent drying agent for protecting products against corrosion, contamination, spoilage, and mould growth. It is formed into small pellets, granules or beads and has a strong affinity for water molecules due to its porous structure. When used as a desiccant, silica gel absorbs moisture from the air and helps keep products dry.

Commonly found in packets labelled “Do Not Eat”, silica gel packs are widely used in food packaging to protect against mould growth and spoilage caused by humidity. Due to its high surface area, water in the air is absorbed between the microscopic pores as the air passes through them. The absorbers contain nanometer void spaces and a tridimensional oxygen and silicon atoms structure. Approved by the Food and Drug Authority of the United States (FDA), the silica gel desiccant is safe to use with food products.

Indicating Silica Gel

Indicating silica gel is developed for monitoring humidity levels, and the desiccant contains a special dye that changes colour depending on the level of moisture present in the surroundings. The moisture indicator changes colour from an anhydrous (dry) to a hydrated (wet) state. Methyl violet and cobalt (II) chloride are the most common forms. When dry, cobalt (II) chloride is a deep blue but turns pink when saturated. Methyl violet changes colour from orange to green and orange.

Molecular Sieve

Molecular Sieves are composed of microporous aluminosilicate m aterials, such as zeolites. The desiccant’s customisable pore openings allow specific molecules to separate from one another by absorbing molecules smaller than the pore openings’ width while excluding the remainder, which enables them to dehydrate, purify, and segregate specific gases and liquids.

aterials, such as zeolites. The desiccant’s customisable pore openings allow specific molecules to separate from one another by absorbing molecules smaller than the pore openings’ width while excluding the remainder, which enables them to dehydrate, purify, and segregate specific gases and liquids.

Molecular sieves can absorb moisture much faster than other desiccants and are commonly used in filtration systems to lower humidity levels. The desiccant can be used in temperatures up to 300°C and absorb up to 22% of its weight. The petroleum sector uses molecular sieves for drying gas in stream assemblies where the water content of gas in the liquid natural gas (LNG) should be less than one ppmv.

Activated Alumina

Activated Alumina is a porous, solid form of Aluminium Oxide (Al2O3) utilised in heavy industrial applications, including adsorbing catalysts and eliminating fluoride and other pollutants. Made from high-purity alumina gel heated and treated with an oxidising agent at very high temperatures, activated alumina also has a very low dust content, making it ideal for applications where dust particles are harmful or disruptive. Due to its excellent adsorptive properties, activated alumina is used in water filtration and gas drying systems.

With a surface area higher than 200m2g, the desiccant can adsorb a wide range of substances, such as gases and liquids, without changing its form or structure. The desiccant is also often used to filter fluoride, arsenic, and selenium from drinking water. The adsorbent’s toughness makes it ideal for high-pressure applications such as Claus catalyst processing to remove pollutants like fluoride, arsenic, and sulfur from fluid streams.

Activated Clay

Activated clay, or bentonite, is a naturally occurring desiccant composed of an expansive mineral matrix. The activation process involves washing the clay with acid to remove impurities and heating it to a high temperature to activate its adsorption properties. The clay desiccants are typically packaged in small sachets or bags and placed inside the packaging of the product they are designed to protect.

Activated clay, or bentonite, is a naturally occurring desiccant composed of an expansive mineral matrix. The activation process involves washing the clay with acid to remove impurities and heating it to a high temperature to activate its adsorption properties. The clay desiccants are typically packaged in small sachets or bags and placed inside the packaging of the product they are designed to protect.

Activated clay desiccant packets are non-toxic and environmentally friendly, making them popular in many industries. They are also reusable, as they can be regenerated by heating them to a high temperature to remove the absorbed moisture, making them a cost-effective option for long-term use.

Activated Carbon

Activated Carbon is a form of graphite known as activated charcoal or activated Coal. Unlike graphite, the material has a random, flawed structure with a wide range of pore sizes, leading to its high surface area and allowing it to have the highest physical adsorption forces. Activated carbon is a cost-effective approach to treating large volumes of gas or water containing low levels of pollutants. Water, air, gas treatment and odour control are all typical uses for the desiccant. At municipal treatment plants and household filtration systems, activated carbon adsorption is a prevalent treatment method for eliminating pollutants from drinking water.

Conclusion

Desiccants are used to protect products from moisture damage and control humidity levels. The right desiccant type for an application depends on various factors, including the amount of water vapour in the environment, the desired adsorption rate, and humidity ranges. Using an appropriate type of desiccant is essential for ensuring product safety and quality control in many industries, such as pharmaceuticals, food processing, and electronics manufacturing.

Stream Peak offers a wide range of desiccants certified through our in-house QA laboratory. Our manufacturing facility in Singapore produces desiccant bags that adhere to ISO 9001 and 14001 certifications. If you’re interested in discovering more about our desiccants and engaging with our packaging engineers, please don’t hesitate to get in touch with us.