Guide on Using Gummed Paper Tapes to Seal Packages

Packaging, often the first physical touchpoint between a product and its recipient, ensures items are delivered securely, without damage. Moreover, where first impressions matter, packaging doubles as a brand ambassador, offering cues on quality, attention to detail, and professionalism. Sealing, a crucial element of this process, ensures the package’s integrity and protects its contents from external factors.

What is Gummed Paper Tape?

Gummed paper tape, sometimes referred to as water-activated tape (WAT) is primarily made from paper. This natural base provides flexibility and strength, making it ideal for sealing packages. The adhesive used is typically a starch-based glue.

When this adhesive comes into contact with water, it activates, becoming sticky and capable of forming a robust bond. Unlike other adhesive tapes that are immediately sticky to the touch, gummed paper tape requires the application of water to its adhesive side for activation. This feature ensures a clean, non-tacky roll that only becomes adhesive upon intent.

Benefits of Using Tapes

Biodegradability: Gummed paper tapes are biodegradable and made primarily of paper and a starch-based adhesive. This means they break down naturally over time, contributing to reduced landfill waste. This is particularly essential in an era where environmental consciousness is paramount.

Since they are derived from renewable resources, gummed paper tapes are a sustainable packaging option. Moreover, their ability to be recycled alongside cardboard boxes eliminates the need for additional sorting, thus streamlining the recycling process.

Strength and Durability: Once the tape is applied to a cardboard box or package, it forms a bond not just on the surface; the adhesive penetrates the cardboard fibres, creating a tamper-evident seal. Once activated with water, the adhesive penetrates the cardboard fibres, creating a robust bond.

This ensures that packages remain sealed throughout the rigors of shipping and handling. Reinforced gummed tapes, with their embedded threads, offer an additional layer of strength, making them ideal for heavy-duty packaging needs. Such tapes resist tearing and ensure the integrity of the package during transit.

Tamper-Evident Sealing: Once the tape bonds with the package, any attempts to remove it will cause visible damage to the box. This is a clear deterrent to unauthorized access and assures recipients of untouched content.

Versatility: The tapes bond effectively with dusty and fiber-heavy cartons, ensuring reliable sealing in various packaging scenarios. These tapes can perform admirably in various temperature conditions. Their adhesive remains effective in cold storage or under the scorching sun, ensuring packages stay sealed.

Customization: Beyond their functional attributes, the tapes can be printed with logos, messages, or handling instructions. This versatility allows businesses to secure their packages and enhance their brand visibility.

Cost-effectiveness

Gummed paper tapes might seem more expensive than common alternatives, such as polypropylene or PVC tapes. However, the strength and durability of gummed tapes mean that, in many cases, only one strip of tape is required to securely seal a package instead of multiple layers with other tapes. While water-activated tape dispensers are an added cost, their efficiency often results in long-term savings. Additionally, these dispensers ensure optimal wetting and consistent tape lengths, reducing wastage.

- Reduced Waste: The inherent strength of gummed paper tapes means fewer materials are used in the first place. When a single strip suffices to seal a box securely, less tape is consumed over time, leading to tangible savings.

- Increased Security: The tamper-evident nature of gummed paper tapes can lead to decreased losses stemming from theft or tampering during shipment. Additionally, the strong bond reduces the risk of packages accidentally opening during transit, potentially saving businesses from refund or reshipment costs.

- Reduced Returns and Damages: With its holding power, packages sealed with gummed paper tape are less likely to open or get damaged. This can lead to a reduction in customer complaints, returns, and the associated costs.

- Operational Efficiency: Sealing boxes become more streamlined with gummed tape, especially when using automated dispensers. This can lead to time savings and increased operational efficiency, which, over time, can contribute to cost reductions.

How to Use for Sealing Packages

Gummed paper tape, with its strong adhesive and sustainable nature, provides a packaging solution for sealing packages. Choosing the right tools, the tape’s dimensions, and the application technique makes it possible to achieve a secure, tamper-evident seal for packages.

Tools Required

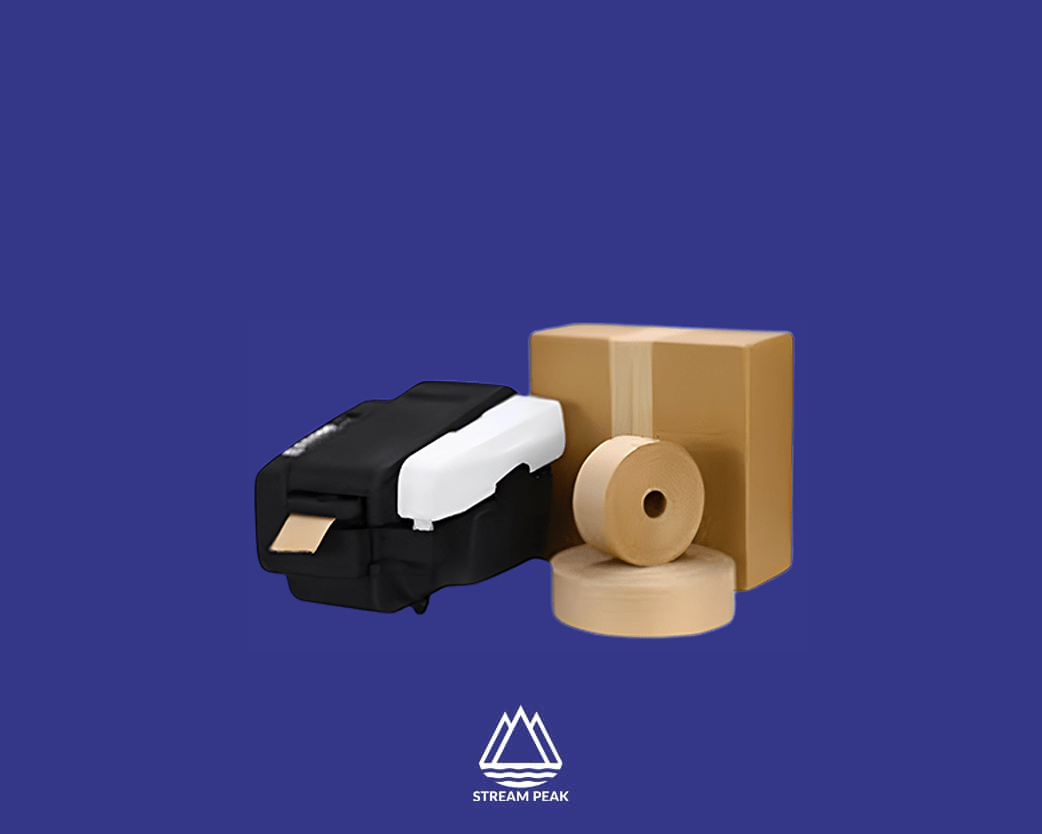

Packaging operations range from low to high volume, and the choice of tools reflects these varying needs. Handheld manual dispensers are available, where one extracts the desired length of tape and then runs it across a moistened brush or sponge to activate the adhesive. This dispenser is particularly apt for operations that don’t require sealing many boxes simultaneously and provides control over the tape length.

On the other hand, there are automatic dispensers – machines that can dispense, wet, and cut the tape with a simple button push. They are the go-to choice for high-volume packaging tasks. Some of these sophisticated machines even come with features that allow preset tape lengths, which ensures uniformity and efficiency in the packaging process.

Choosing the Right Width and Length

The dimensions of the tape play a crucial role in ensuring a package’s security. Typically, the width of the tape selected should align with the weight and size of the package. Standard cartons are generally well-served by tapes that are 2 to 3 inches wide.

However, for more substantial or bulkier packages, wider tapes are often needed to guarantee a robust bond. The length is another consideration. It’s recommended that the tape should extend about 2 to 3 inches on either side of the box flap, ensuring a secure hold. For wider boxes, it’s advisable to use longer lengths of tape to provide more coverage, thus ensuring that the tape forms an effective bond with the box for a secure seal.

Ensuring a Smooth Finish

Begin by ensuring that the box flaps are neatly closed and aligned. This provides a smooth surface for the tape and reduces the chances of wrinkles. When applying the tape, start from one end and gradually smooth it towards the other.

This methodical application helps prevent air bubbles from getting trapped under the tape. Once the tape is positioned, press down firmly from the centre outwards, ensuring maximum contact with the surface. Use a tape tamp or roller to smooth it out, eliminating any potential bubbles or wrinkles.

Application Technique

Whether a manual or automatic dispenser is used, the tape must be sufficiently wetted. An overabundance of water might compromise the adhesive’s strength, while scant water might not activate it sufficiently. The objective is to achieve a uniformly damp feel across the tape’s adhesive side.

Once wetted, it’s essential to position the tape accurately. It should cover the seam where the box flaps converge and extend uniformly on both sides. In situations where the package is larger, applying tape across the mid-seam and the box’s edges can offer added security.

After positioning, the tape should be pressed firmly, ensuring it’s smooth and free from bubbles or wrinkles. This step is crucial as it establishes maximum contact between the tape and the box, fostering a potent bond. While tools, such as a tape tamp or roller, can aid this process, a manual hand-press technique is also effective, especially when dealing with a smaller number of packages.

Storage Conditions

Sometimes, especially when not handled correctly or stored under improper conditions, the gummed paper tape may stick to itself or even tear during the application process.

Keeping the tape in its original packaging and storing it in a cool, dry place can prevent these issues. When handling, ensure hands are clean and dry. Using dispensers can also offer better control during application, reducing the risk of the tape sticking to itself or tearing.

Store gummed paper tape in a cool, dry place. Extreme temperatures and high humidity levels can affect the tape’s adhesive properties. A room temperature ranging from 18°C to 21°C (64°F to 70°F) is generally ideal. Prolonged exposure to UV rays can degrade the adhesive.

Always store tapes away from direct sunlight or areas with high UV exposure. Whenever possible, keep the tape rolls in their original packaging. This not only prevents them from collecting dust but also helps in retaining the adhesive’s moisture content.

Storing the tape in a controlled environment is beneficial for humid environments, perhaps with desiccants. When applying, ensure that the tape is not overly wet. Consider storing the tape in a slightly warmer area before use in cold conditions, ensuring that the adhesive can be activated correctly. Moreover, using warm (not hot) water for activation can offset the cold’s impact, leading to better adhesion.

Optimal Wetting Techniques

Using room temperature water is generally deemed the best approach, as extremely cold or hot water can either inadequately activate or overly soften the adhesive. The goal is to achieve a tape surface that is evenly damp, neither over-saturated nor under-wetted.

Both conditions can compromise the tape’s bonding strength. Investing in dispensers, be it manual or automatic, is a wise choice for those engaged in routine sealing tasks. These tools are engineered to provide a consistent wetting mechanism, ensuring every tape application is on point.

On certain occasions, the tape might not adhere well to the package, leading to potential security risks or presenting an unprofessional appearance. Ensure that the tape is uniformly dampened, avoiding over-saturation or under-wetting. Additionally, pressing the tape firmly once applied can increase the bonding strength. Ensuring the box’s surface is clean and free from dust or oily residues is also essential. Using a roller or tape tamp can further ensure a strong bond.

Conclusion

As the packaging industry evolves, embracing solutions prioritising product security and ecological impact is essential. Gummed paper tapes perfectly embody this balance. For businesses and individuals looking for an effective and environmentally-conscious way to seal packages, these tapes present a solution that doesn’t compromise quality or our planet’s well-being.

Stream Peak offers a comprehensive range of water-activated paper tape featuring reinforced and non-reinforced variants. Our dispensers ensure efficient output at 30cm per second, streamlining the packaging process. With one-touch dispensing, you can easily adjust tape lengths ranging from 15cm to 210cm to fit unique packaging needs. Please contact us for detailed insights or to schedule a no-obligation consultation with our packaging engineers.