VCI poly tubing protects metal parts and components from corrosion during storage or transportation. VCI technology is based on the principle of releasing volatile corrosion inhibitors, which form a protective layer on the metal surface and prevent the formation of rust or corrosion.

Effective Corrosion Prevention

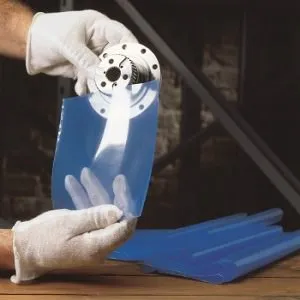

The corrosion-protective packaging is made from a blend of polyethene resin and VCI additives. The tubing is transparent and comes in various widths and thicknesses to accommodate different sizes of metal parts. It is designed to be sealed and shrunk using heat, forming a customized protective cover around the metal item.

When the VCI poly tubing is heat-sealed, it creates an airtight environment around the metal object. The VCI additives in the tubing vaporize and migrate to the metal surface, forming a thin layer of corrosion inhibitors. This layer provides long-lasting protection against moisture and corrosive elements, such as oxygen and humidity, thus preventing the onset of rust or corrosion.

Safeguarding Metal Products

VCI poly tubing can be used in industries where metal parts or products need to be stored or shipped over extended periods. It offers a cost-effective and efficient solution for protecting items of various shapes and sizes, including machined parts, automotive components, tools, and machinery. The tubing is easy to use, as it can be cut to desired lengths, heat-sealed, and shrunk with a heat gun or shrink tunnel.

- Protects a wide range of ferrous metals, steel, and aluminium

- Recyclable, nitrite- and amine-free

- Heat-sealable, tear-resistant

- Long-term corrosion protection

- Safe and easy to use

- Parts remain clean, dry, and ready to use immediately, without additional cleaning or rework

- Compatible with rust-preventive liquids, papers, and emitters

- Thickness (Gauge): 4mils/100μm

- Burst Strength: 21.9psi/151kPa

- Puncture Strength: 1315g/2.9lb

- Tear Resistance:

- Machine Direction – 428.8gf/4.2N/ply

- Transverse Direction – 1232gf/12.1N/ply

- Tensile Strength at Break:

- Machine Direction – 3148psi/21.7MPa

- Transverse Direction – 2143psi/14.8MPa

- Elongation at Break:

- Machine Direction – 818%

- Transverse Direction – 1025%

- Inside Dry Storage: 24 Months

- Recommended to use within 12 months of purchase

| Width | Length | Thickness | Color | Packaging |

| 4 inch | 1500′ | 4 Mil | Yellow | 1 Roll |

| 6 inch | 500′ | 4 Mil | Yellow | 4 Rolls |

| 8 inch | 500′ | 4 Mil | Yellow | 1 Roll |

| 12 inch | 1000′ | 4 Mil | Yellow | 1 Roll |

| 16 inch | 500′ | 4 Mil | Yellow | 1 Roll |

| 24 inch | 500′ | 4 Mil | Yellow | 1 Roll |

| 36 inch | 500′ | 4 Mil | Yellow | 1 Roll |

| 48 inch | 500′ | 4 Mil | Yellow | 1 Roll |