Choosing the Right Forklift Proximity Alert System

Forklift accidents are often severe and account for over 10% of all workplace injuries. Forklifts being extremely useful can also be equally dangerous – they weigh around 9,000 pounds and travel up to 18 mph. And unlike ordinary cars, they have brakes only on the front wheels. Their weight is also not equally distributed, with the rear end being heavier to compensate for the heavy loads in the front during the movement of goods. Forklift safety depends on two factors which are proper training and the use of forklift safety products.

Forklift Safety Procedures

Operators and pedestrians require training under occupational safety standards set by international agencies. Only licensed operators must be allowed to operate the Forklift with wear appropriate safety gear. The area of operation must be even and free from loose objects. The load on the Forklift must be evenly distributed and not overloaded.

And most importantly, employers must implement a floor marking system to keep everyone safe. While operator and pedestrian training are essential for safety, innovative safety products will safeguard people and assets—from basic seat belts and safety signs to advanced proximity warning systems.

Understanding Proximity Alert Systems

Proximity detection systems are advanced safety technologies designed to warn individuals or operators of potential collisions or dangerous situations based on the proximity of objects or other individuals. These systems are commonly used in various industries and applications to enhance safety and prevent accidents.

Proximity alert systems provide timely warnings, allowing people to take necessary precautions or corrective actions to avoid accidents. These systems’ specific functionality and features may vary depending on the application, but they often rely on sensors and detection mechanisms to monitor the surrounding environment.

The warning system will help with safety for both operators and pedestrians. An audible and visual warning not only helps to avoid a mishap but also prevents infrastructure damage. And if the vehicle is too close, the system stops the forklift automatically. The proximity alert system uses either magnetic field generators or radio-frequency identification.

Radio-Frequency Identification Systems

RFID-based detection alert systems were once considered expensive and required significant investment. However, today, with the advancement of technology, the cost of such systems has reduced considerably. The system consists of a control unit and antenna mounted on the vehicle.

RFID tags carried by pedestrians, together with radiofrequency detection zones, thus created around the Forklift. An audible and visual alert occurs whenever a pedestrian or tagged object enters the antenna range. The detection antenna has a 3 to 9-meter detection zone. It operates 360º around the vehicle, which implies that the tags need not be in the line of sight of the detection antenna and can be detected even in places of poor visibility. Also, single or multiple antennas can be fitted depending on the area and vehicle size.

Electromagnetic fields in RFID systems help identify and track tags. Depending on their usage, RFID tags can either collect energy from an RFID reader’s radio waves or have a local power source that can operate hundreds of meters away from the RFID reader. The RFID tags can be attached to a lanyard, placed inside a high-visibility jacket, or fitted inside a detection cone. An alarm will occur whenever a person or object is detected within the detection antenna’s 3- to 9-meter zone.

Magnetic Field Sensing Systems

Systems using magnetic field detectors use electromagnetic fields to measure direction, rotation, presence, angle, and current to detect any disturbances in the area.

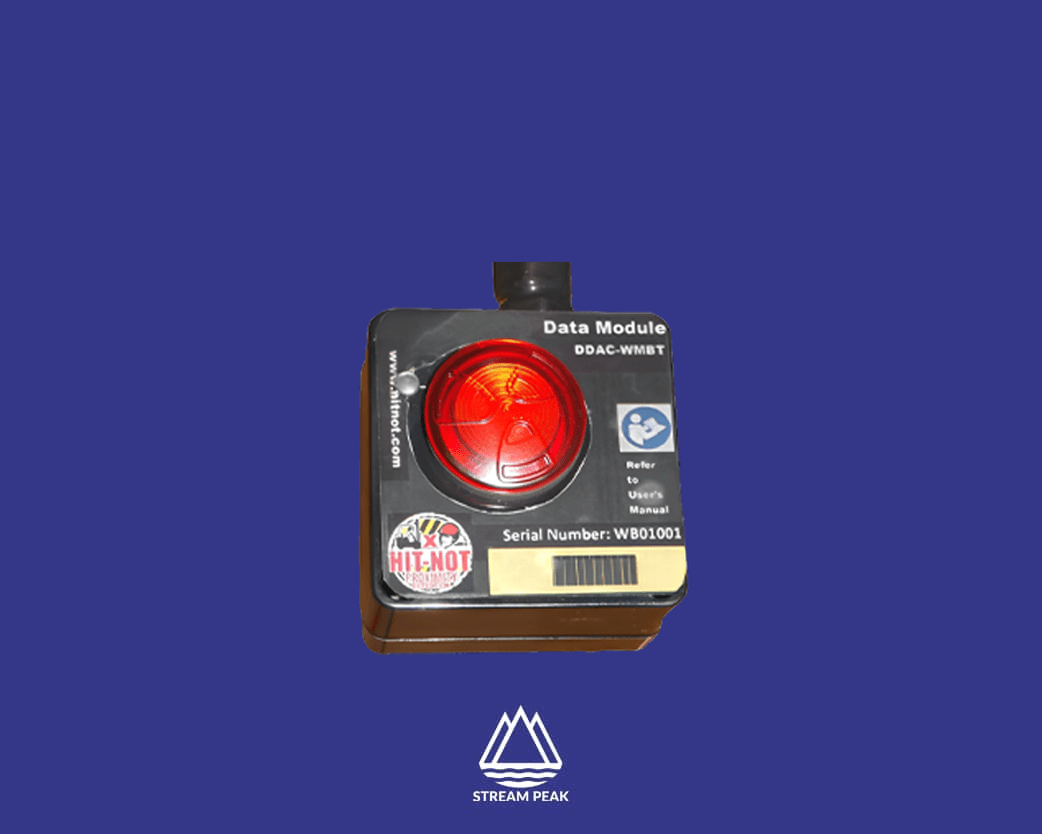

The system works when there’s continuous communication between its two main components, the Equipment Protection Unit or EPU and the Personal Protection Unit or the PPU.

The EPU is mounted onto the Forklift and fitted with an audible and visual alert system to alert operators in a potentially hazardous situation.

It contains a magnetic antenna to generate a magnetic field with a ferrite core. The PPU is powered by lithium-thionyl chloride batteries and is worn by pedestrians as a safety vest or a hat. It provides an alert either as a vibration or as an audible alert, and if the PPU deforms the magnetic field of the EPU, both systems will sound an alarm.

Unlike RFID-based systems, magnetic field-based proximity systems can pass through walls and structures. They can be used even in blind corners and warn through mounds of containers. The system is used to not only detect people and assets but also avoid collisions between two forklifts. Both operators receive an alert when two forklifts fitted with proximity alert systems come in close contact. The system can also be customised to meet the unique needs of a warehouse or establishment. Some of these proximity alert components include:

- Area Control: The system can be configured to match the specific needs of the work environment. The magnetic field generator is placed on any equipment or vehicle according to the establishment’s safety concerns. It can operate together with multiple Forklifts and multiple personal alarm devices. Similarly, the safety system can be customised for congested and diverse traffic areas.

- Access Control: The alert system can be turned off if the forklift passes through a protected area. Similarly, managers can restrict access to users or vehicles not carrying the PPU or EPU and prevent them from entering protected areas.

- Remote Event Monitoring: This feature allows a business to record and assess its safety events and other operational information. Email reports are automatically generated to offer users information about a wide range of factors like warning alerts, danger alerts, collision avoidance alerts between vehicles, and even detect violations, if any, in an identified area. Use the report to determine the need for personnel training, reduce the loss of PPU tags, identify inactive PPU tags, and even study traffic problems. The information can also be customised to match an establishment’s specific requirements. For regular updates, users can access online dashboards.

Benefits of Forklift Detection Alert Systems

Forklift proximity detection systems offer benefits that significantly enhance safety and efficiency in industrial environments where forklifts are commonly used. These systems use advanced sensor technology to detect objects, obstacles, or pedestrians near the forklift, providing real-time warnings to the operator. Here are some key advantages:

- Accident Prevention: The primary benefit is accident prevention. Forklifts operate in busy and often crowded environments, such as warehouses, distribution centres, and manufacturing facilities. The system’s sensors can detect potential collision risks with other forklifts, stationary objects, or pedestrians. By providing early warnings to the operator, the system helps prevent accidents and reduces the risk of injuries and property damage.

- Improved Operator Awareness: Forklift operators may have limited visibility, especially when carrying large loads or reversing. The alert system acts as an extra set of eyes, notifying the operator of any blind spots or hidden obstacles, thereby reducing the likelihood of collisions.

- Reduces Downtime and Damages: Forklift accidents can lead to costly downtime for repairs and cause damage to the forklift, the load being carried, and the surrounding infrastructure. By minimising collisions and accidents, the systems help companies save money on repairs and maintenance, improving overall productivity.

- Employee Confidence and Morale: A safer workplace fosters employee confidence and morale. When workers feel that their safety is prioritised, they are more likely to be motivated, focused, and satisfied with their work, leading to increased productivity and reduced employee turnover.

Conclusion

Forklift detection alert systems improve workplace safety and reduce the risk of accidents in industrial environments. These safety technologies use sensor-based detection to provide timely warnings to forklift operators, enabling them to avoid collisions with objects, obstacles, or pedestrians. By preventing accidents, these systems not only protect the well-being of workers and assets but also enhance overall operational efficiency by minimising downtime and costly damages.

Find out more about Stream Peak’s forklift safety proximity alert system. Contact us for a no-obligation demonstration and experience the safety features. Our team can arrange to leave demo units in your warehouse, allowing you to thoroughly test and understand the system’s effectiveness in enhancing workplace safety. Take the proactive step towards accident prevention.