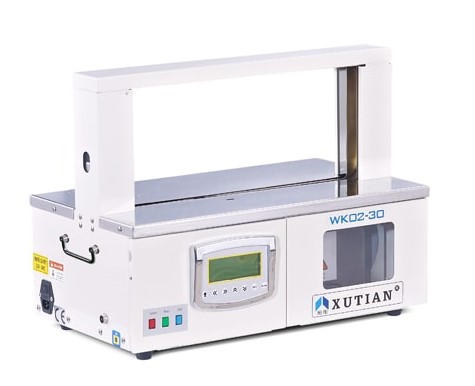

Tabletop paper banding machines offer mobility and ease of use. These strapping equipment feature a short table designed for small formats, making them highly user-friendly and requiring minimal maintenance.

Convenient Setup for Swift Bundling

To initiate the banding process, place the product on the table of the paper banding machine and activate the automatic photo eye or utilise a foot pedal. The tabletop paper banding machine utilises a heat sealing mechanism, offering a packing speed of approximately 20 packs per minute. This enables efficient paper binding, resulting in a tidy seal around the item.

To use the straps for packaging straps, follow these steps:

- Convenient Setup: Place the items or packages on the machine’s conveyor or worktable.

- Secure Bundling: The machine feeds the strapping material around the item, applying tension to ensure a tight and secure bundle.

- Effortless Sealing: Once the desired tension is achieved, the machine seals the banding material using heat and friction, creating a neat seal around the item.

- Neat Trimming: Excess strapping material is automatically cut off, leaving behind a clean and trimmed band around the bundled items.

User-Friendly and Low Maintenance

Using tabletop paper banding machines achieves swift and reliable bundling, enhancing productivity and efficiency in operations. The banding machines can be used for various applications, such as packaging small boxes or bundling brochures and envelopes.

- 60 Seconds Pre-Heating time

- Heat Sealing

- Applicable for both paper band and OPP film

- Can connect to a jumbo roller dispenser to load 500-800 meters roll

- AC motor Power

- Tape Dimensions (W x TH x L): 29.44mm x 0.1 mm x 190mm

- Tape Material: Paper/OPP Film

- Strapping Speed: ≤ 3 seconds

- Tension: 5 – 40N

- Package Dimensions: Max: 460 x 200, Min: 30 x 10

- Machine Dimensions (L x W x H): 630 x 364 x 474

- Power Supply: 220V 50 Hz/60 Hz; 110V 60 Hz

- Electrical Power: 80W

- Net Weight: 32.5 kg

| Model | SPI 20 | SPI 30 |

| Applicable Material | OPP film or PP band | OPP film or PP band |

| Material Specification | Width: 19.2-19.6mm Thickness: 120mic Length: 150meters Core: 40mm |

Width: 29.2-29.6mm Thickness: 120mic Length: 150meters Core: 40mm |

| Arch Size | 460*200mm | 460*200mm |

| Banding Size | Min: 30*10mm Max: 460*180mm | Min: 30*10mm Max: 460*180mm |

| Power Supply | 220V 50hz 1phase or 110V 60hz 1phase | 220V 50hz 1phase or 110V 60hz 1phase |

| Power Rate | 80W | 80W |

| Control System | PCB+Key board control panel | PCB+Key board control panel |

| Banding Speed | 25 bands/Minute | 25 bands/Minute |

| Banding Tension | 5-40N | 5-40N |

| Welding Method | Heat Sealing | Heat Sealing |

| NW | 32kg | 32kg |

| Machine Dimension | L 611 x W 364 x H 475mm | L 611 x W 364 x H 475mm |

Automatic Banding Machine Brochure: Download