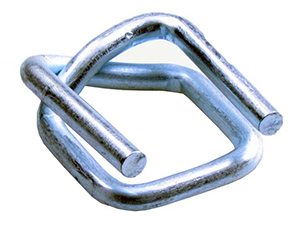

Galvanized wire buckles are metal fasteners used with composite strapping for securing materials together. The wire buckle’s surface goes through a process with added protective zinc coating.

Hardness and Corrosion Resistance

Galvanized wire buckles are made of steel and are a flat, W-shaped piece with two prongs or legs extending from the open ends of the U-shape. These prongs secure and tighten a strap or band around an object.

With its “self-lock” feature, the wire buckles are slip resistance and maximum holding power. Wire Buckles have a small dent at the corner of the tensioning side to allow the buckle to close more tightly, making it more effective, less slippery, and more robust.

To use a galvanized wire buckle, the composite strap is threaded through the W-shaped opening, and the strap is then tightened around the object being secured. The prongs of the buckle are bent or folded over the strap to lock it in place, creating a secure fastening.

Slip Resistance and Stong Holding

The galvanized coating on the buckle provides corrosion resistance, making it suitable for outdoor and humid environments where exposure to moisture or harsh conditions may occur. The coating helps protect the buckle from rust and extends its lifespan.

Galvanized wire buckles are available in different sizes and strengths to accommodate various strapping applications. They can be used in the packaging, shipping, and bundling industries. These buckles are simple, cost-effective, and reliable fastening solutions for bundling and securing items during transportation or storage.

- Material: Bended steel wire

- Shelf life: 12 months

- Wire treatment: Galvanization process that involves applying a protective zinc coating to steel, effectively preventing rust and corrosion

Sizes Available

- 13mm

- 16mm

- 19mm

- 25mm

- 32mm

- 38mm

Galvanised Wire Buckle Product Brochure: Download