Enhancing Cargo Protection for Secure Container Transportation

Securely transporting goods in shipping containers is vital for ensuring the integrity and safety of cargo during transit. To address this crucial aspect of global trade, industry professionals have turned to a combination of innovative packaging solutions such as composite strapping, lashing belts, and dunnage bags.

In this blog post, we will explore the importance of securing goods in containers and discuss how the strategic use of composite strapping, lashing belts, and dunnage bags can enhance cargo protection.

Understanding the Need for Cargo Security

Shipping containers are subjected to various dynamic forces, including rough seas, stacking pressure, sudden braking, and unexpected movements. These factors can lead to cargo shifting, damage, and even safety hazards without proper security measures. Implementing effective cargo-securing methods is essential to mitigate these risks.

- Protection of Cargo: Securing goods in containers helps protect them from damage during transit. Containers are subject to various dynamic forces, such as rough seas, sudden movements, and changes in temperature and humidity. Properly secured cargo reduces the risk of shifting, collision, or impact, minimizing the potential for damage or loss.

- Safety Considerations: Ensuring cargo security is about protecting the goods and maintaining the safety of those involved in the transportation process. Unsecured cargo can shift or fall during transport, posing hazards to workers, drivers, and other individuals nearby. Securely fastening cargo can significantly reduce the risk of accidents, injuries, or fatalities.

- Regulatory Compliance: Many countries and international organizations have established regulations and guidelines regarding container cargo securing. Compliance with these standards is essential to avoid penalties, delays, and potential legal issues. By adhering to the prescribed cargo-securing practices, businesses can demonstrate their commitment to safety and regulatory compliance.

- Prevention of Theft and Pilferage: Cargo theft and pilferage are significant concerns in the shipping industry. Properly securing goods in containers minimises the chances of unauthorized access and theft. Security measures such as seals, locks, tamper-evident devices, and effective cargo-securing techniques help deter theft and safeguard valuable shipments.

- Stability and Efficiency in Transportation: Properly secured cargo enhances the stability and efficiency of transportation operations. When goods are secured in containers, they are less likely to shift or become unstable, reducing the risk of accidents and delays. Well-secured cargo facilitates more efficient loading and unloading processes, ensuring smoother logistics operations and optimized supply chain management.

- Protection of Brand Reputation: Cargo damage or loss can have severe consequences for businesses, including negative impacts on brand reputation and customer trust. By investing in proper cargo-securing measures, companies demonstrate their commitment to delivering goods in pristine condition. This helps maintain customer satisfaction, loyalty, and a positive brand image.

Composite Strapping

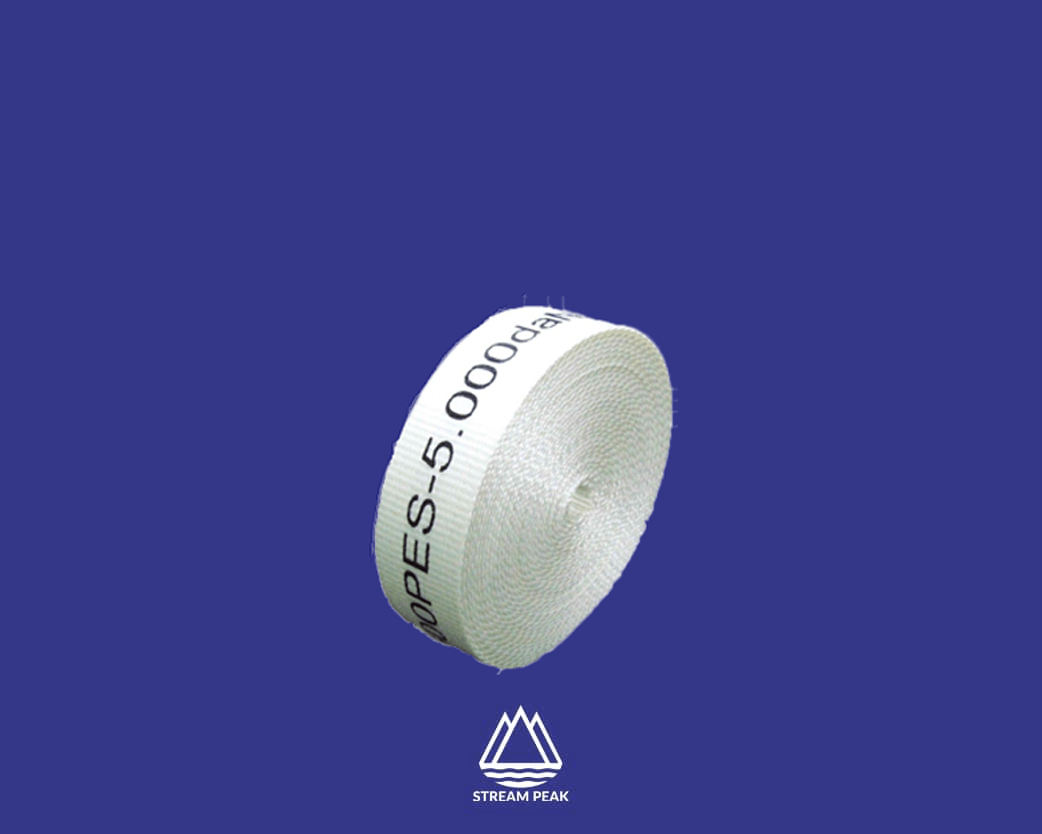

Composite strapping is a strong and flexible alternative to traditional steel strapping. Its combination of high-tenacity polyester filaments and a polymer coating delivers exceptional strength, elongation, and resistance to corrosion and UV rays.

Key benefits of composite strapping include:

- High Tensile Strength: Composite strapping can withstand significant pressure and loads, ensuring cargo remains secure during transit.

- Shock Absorption: Its flexibility allows it to absorb shocks and vibrations, reducing the risk of cargo movement and damage.

- Lightweight and Safe: Composite strapping is lighter than steel strapping, making it easier to handle during application and minimizing the risk of injuries.

Using composite strapping effectively involves assessing cargo and strapping requirements, preparing the cargo and container, selecting the correct tools and accessories, positioning and tensioning the strapping, and securing it with appropriate buckles or seals.

Repeat the process for the entire cargo, inspecting and testing the strapping for proper tension and security, and documenting the process while labelling the container. Following the manufacturer’s instructions and guidelines for the specific composite strapping is important.

Lashing Belts

Lashing belts, made of durable polyester webbing, are designed to secure cargo within containers and prevent shifting during transportation. They offer several advantages:

- Customizable and Flexible: Lashing belts are available in different lengths and configurations, allowing for tailored usage based on cargo dimensions and requirements.

- Exceptional Load Capacity: The high tensile strength of polyester webbing ensures lashing belts can withstand substantial forces, maintaining cargo stability.

- Durability and Reusability: Lashing belts are designed for long-lasting performance, providing a cost-effective solution that can be reused for multiple shipments.

Using lashing belts effectively involves positioning the belts around the cargo, adjusting the length and tension to ensure a secure grip, fastening the belts using buckles or tensioning devices, inspecting the belts for proper tension and security, and repeating the process for multiple lashing points as needed. Following proper application techniques and manufacturer guidelines is important to ensure optimal cargo securing.

Dunnage Bags

Dunnage bags are inflatable cushions made of sturdy materials such as polypropylene. Placed in the gaps between cargo and container walls, they provide additional support and prevent cargo movement. Key benefits of dunnage bags include:

- Efficient Void Filling: Dunnage bags fill empty spaces in containers, reducing the risk of cargo shifting and potential damage.

- Pressure Distribution: By evenly distributing pressure, dunnage bags help maintain cargo stability and minimize the impact of dynamic forces.

- Easy Installation and Removal: Dunnage bags are quick to install and can be deflated and reused, offering convenience and cost-effectiveness.

Using dunnage bags effectively involves placing the deflated bags in the gaps between cargo and container walls, inflating the bags using an air compressor or pump to fill the voids, adjusting the pressure to provide proper support and stability, securing the inflation valve to prevent air leakage, inspecting the bags for any damage or leaks, and deflating and removing the bags after transportation for reuse or disposal.

It’s important to select the appropriate size and type of dunnage bags for the specific cargo and container dimensions and follow the manufacturer’s instructions for proper inflation and usage.

Best Practices for Optimal Cargo Security

To maximize the effectiveness of composite strapping, lashing belts, and dunnage bags, it is important to follow these best practices: Ensure proper tensioning and placement of composite strapping, lashing belts, and dunnage bags to secure cargo effectively.

Regularly inspect the condition of the securing materials and dunnage bags, replacing them if damaged or worn. Train personnel involved in cargo handling to ensure proper application and use of securing techniques.

Conclusion

Securing goods in shipping containers is critical to maintaining cargo integrity during transit. The strategic use of composite strapping, lashing belts, and dunnage bags provide a comprehensive load-securement packaging solution to enhance cargo protection.

By employing these innovative methods, shippers and logistics professionals can minimize cargo damage, reduce financial losses, and ensure the safe delivery of goods to their destinations. Prioritizing effective cargo-securing measures is an investment in the reliability and success of global trade.