Container Lashing Safety Points and Tips for Cargo Security

Container lashing safety is of importance in the shipping industry. Millions of containers carry cargo daily across seas, roads, and railways. Containers rely on secure lashing to withstand the harsh forces of ocean waves and maintain stability during land transport. Secure lashing is essential to withstand forces during transport and prevent accidents, environmental damage, and financial losses.

This article highlights key considerations and best practices for container lashing safety. We will cover regulations, equipment, techniques, training, and vigilance to understand the significance and necessary measures for container lashing safety in shipping.

Importance of Container Lashing

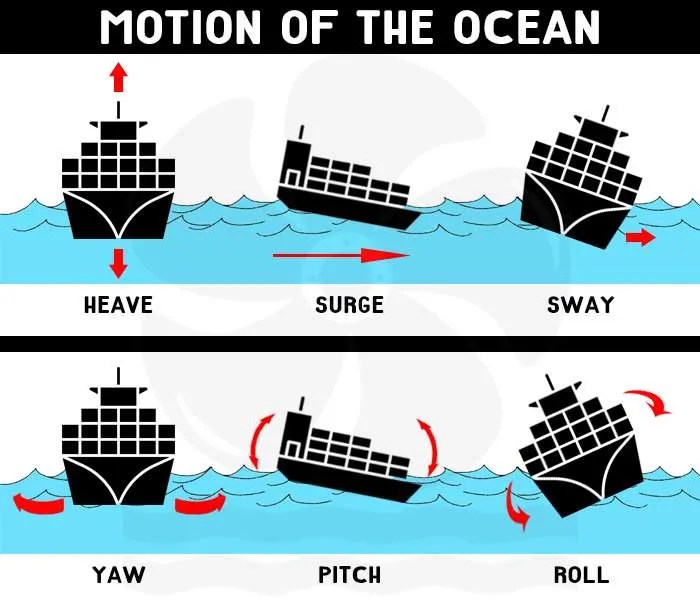

During transportation, containers are subjected to various forces, including the rolling and pitching of ships, the vibrations of trucks and trains, and sudden movements during handling. When properly applied, lashings prevent cargo from shifting, tipping, or colliding with the container walls or other items.

During transportation, containers are subjected to various forces, including the rolling and pitching of ships, the vibrations of trucks and trains, and sudden movements during handling. When properly applied, lashings prevent cargo from shifting, tipping, or colliding with the container walls or other items.

Proper container lashing safeguards the personnel involved in container handling operations. Unsecured containers can pose serious risks when loaded or unloaded, potentially causing accidents, injuries, or even fatalities.

Its significance extends from securing goods to maintaining vessel stability and regulatory compliance. Understanding and implementing proper container lashing techniques and equipment is essential in safeguarding the integrity and safety of the global shipping industry.

Regulatory Framework

Container lashing safety is subject to a comprehensive regulatory framework that spans international and local jurisdictions. These regulations are in place to establish standardized safety procedures and ensure compliance across the shipping industry. Understanding and adhering to these regulations is crucial for safe and responsible container lashing practices.

International Maritime Organization (IMO): The IMO, a specialized agency of the United Nations, sets global standards for the safety and security of shipping. The IMO’s guidelines include recommendations for securing cargo within containers. These recommendations are outlined in the “Code of Safe Practice for Cargo Stowage and Securing” (CSS Code).

International Convention for the Safety of Life at Sea (SOLAS): SOLAS, an international treaty, sets safety standards for the construction, equipment, and operation of ships. SOLAS requires that all cargo, including containers, be properly stowed and secured to prevent accidents during sea transport.

International Convention for Safe Containers (CSC): The CSC mandates the safety inspection and certification of containers used in international trade. Containers must meet specific structural and safety standards, ensuring they can be securely lashed and handled.

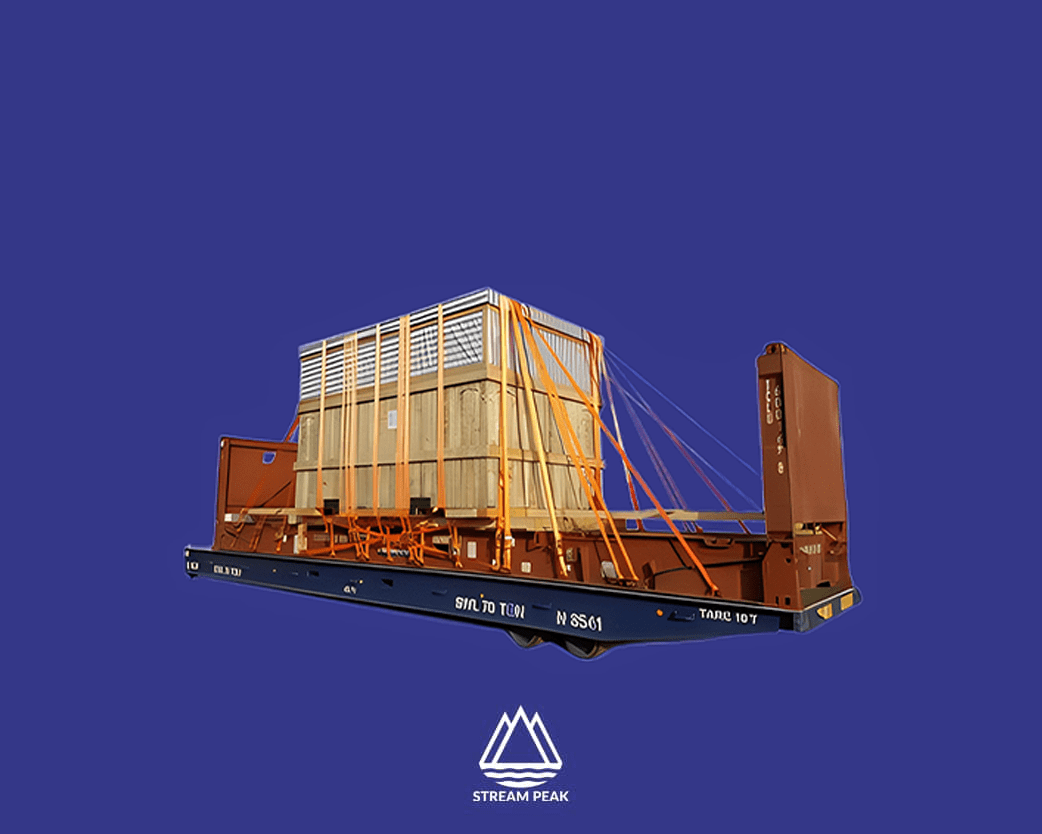

Container Lashing Tools

Container lashing tools are essential in ensuring cargo security within shipping containers. These tools are designed to facilitate the proper tensioning and securing of lashings, ensuring that containers and their contents remain stable during transit. Here are some of the most commonly used container-lashing tools:

Tensioners: Tensioners are pivotal for tightening lashings such as chains, wires, or straps. They come in various designs, including manual, pneumatic, and battery-operated tensioners. Manual tensioners require physical effort to tighten lashings, while pneumatic and hydraulic options offer greater efficiency.

Corner Protectors: Egde board protectors prevent damage to cargo and lashings at the sharp edges of containers. They are typically made of durable materials like plastic or rubber. Corner protectors safeguard both the cargo and the integrity of the lashings.

Dunnage Bags: Dunnage bags, also known as airbags or inflatable bags, fill empty spaces within containers. They prevent cargo from shifting during transit, reducing the risk of damage. Dunnage bags are inflated using compressed air and are available in various sizes to suit different container dimensions.

Lashing belts: Lashing belts secure lashings by providing leverage and tension. These straps are versatile and can be used with various load buckles.

Load Binders: Load binders, also known as chain binders, are used to tighten chains securely. They are commonly used for heavy and oversized cargo. Load binders come in lever and ratchet styles, each with its own advantages.

Wire Rope Clips and Thimbles: These tools are designed for wire rope lashings. Wire rope clips secure the ends of wire ropes, while thimbles protect the rope from wear and tear.

Chain Hooks and Binders: Chain hooks attach chains to anchor points on containers or cargo. Binders, as mentioned earlier, are used to tension and secure chains.

Safety Precautions for Safe Lashing and De-lashing Activities

The lashing specialist oversees the lashing and de-lashing of the containers. The people commissioned to work with the lashing and de-lashing of cargo should be qualified and trained. There should also be clear communication between crew members during lashing activities. Handing cargo containers requires good, safe practices to carry them out safely. Below are some safety tips for lashing operations.

- Wear proper Personal Protective Equipment (PPE) to protect yourself, e.g., reflective vest, steel toe shoes, hard helmet, gloves, etc.

- Work platforms, railing, steps, and catwalks should be inspected before operations

- Stretch and warm up before performing physical work

- Use a back support belt and use the knee to lift

- Be cautious when walking near the ship

- Do not walk under suspended loads such as gantry and hanging containers

- Use clear communication and have a good understanding of hand signals

- Lashing specialists planning and supervising the stowage and securing of cargo should know the application and content of the Cargo Securing Manual (CSM)

- The safe stowage and securing of cargo depend on proper planning, execution, and supervision

- Only lashing specialists should spanner tight the lashings

- Lashings and securing should be per CSM guidelines

- Be careful while walking over the rods and twist locks while working

- Always keep the lashing equipment in its assigned place or on the side of the walking path

- Be careful of fall hazards when lashing outside containers on the hatch cover or pedestal.

- A fall arrester or safety harness must be used by workers when operating aloft.

- Always be safe from co-workers during lashing or unlashing containers, as long rods can be hazardous if not handled properly.

- Do not lash or unlash anything closer than at least 3 containers widths away from other co-workers.

- Do not loosen a turnbuckle and leave the rods hanging. When securing a rod, the turnbuckle must be tightened right away.

- Always work in pairs when handling rods and turnbuckles

- Always report defective lashing gear, defective ship’s railing, or any other inadequate structure or system involved in the operation to the concerned person or ship’s staff

Points to Take Note of while Securing Cargo

- An excellent tight stowage of cargo containers on ships may prevent the need to completely secure it only if the cargo is appropriately packaged and there are no heavy components.

- It is required to secure large and heavy units even if the surrounding area is packed with other cargo, as such units can move or fall.

- Independent lashings must be secured only to appropriate strong points of the ship’s fittings and structure, ideally the specified lashing points.

- Before stowing, ensure the stack weights are correct, as it is critical not to exceed the stack’s permitted weights. Otherwise, the deck container base of the stack could collapse. If the stow is too heavy, the lashings may not be strong enough to keep the containers secure if inclement weather occurs.

- Examine containers for defects, significantly the corner posts. The corner posts must withstand significant compression forces caused by static weights from stowed containers on top and dynamic forces generated by the ship’s rolling, heaving, and pitching. (Reject damaged containers as containers with defective corner posts are prone to falling.)

- Never overtighten lashing rods. Overtightening can put the lashing rods under excessive strain, increasing the pre-tension by a few tons, which can cause them to collapse when under load.

- Avoid loading heavy containers above light containers and at the top of a stack.

Inspection and Maintenance

Regularly inspecting and maintaining lashing equipment prolongs equipment life while reducing the risks of accidents, cargo damage, and costly downtime. The safety of personnel engaged in container lashing hinges on well-maintained equipment. Faulty gear can result in accidents, injuries, or cargo harm.

Consistent inspections ensure lashings are always in optimal condition, securely safeguarding the cargo. International and local regulations often mandate lashing equipment to be in good working order. Compliance is essential to sidestep fines and penalties. Proactive maintenance additionally extends equipment life, curbing the need for frequent replacements and long-term cost savings.

Identifying and Addressing Potential Issues

Conducting regular visual inspections of lashing equipment is a fundamental practice. During these inspections, it is essential to carefully scrutinize the equipment for any signs of wear, corrosion, loose components, or damage. Paying particular attention to critical areas such as hooks, chains, straps, and tensioning devices ensures a thorough evaluation.

Periodic testing of the functionality of tensioning devices, including ratchets and winches, is equally crucial. This testing aims to confirm that these devices operate smoothly and securely tighten lashings. Prompt action is necessary if any worn, damaged, or corroded components are identified, encompassing chains, wires, straps, hooks, and fasteners.

Maintaining the equipment also involves the regular application of lubrication to moving parts. Lubrication serves to prevent rust and ensures the smooth operation of various components. Following the manufacturer’s recommendations regarding intervals and types of lubricants is imperative for proper maintenance.

Conclusion

From understanding the regulatory framework governing container lashing to implementing proper techniques and safety precautions, it’s evident that a comprehensive approach is necessary. This approach encompasses regular inspection and maintenance, which not only prolongs the life of equipment but also minimizes the potential risks of accidents, cargo damage, and costly downtime.

Stream Peak offers extensive load securement solutions designed to safeguard shipments during transportation. Connect with our packaging engineers for a no-obligation consultation regarding container lashing. Additionally, we provide training services to meet specific lashing requirements.