Air pillow machines, also known as air cushion machines or air packaging systems, create air-filled cushions and pillows for packaging purposes. It provides cushioning and protection for fragile or delicate items during transit.

Air Packaging Cushioning Systems

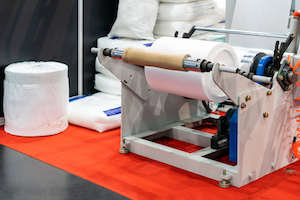

The air pillow packaging machine is a compact unit that generates and inflates air pillows on demand. It uses rolls or stacks of flat plastic film made of paper, polythene or polypropylene, which are fed into the machine. The machine then seals and inflates the film, creating individual air-filled cushions or a continuous chain of interconnected air pillows.

The inflatable air pillows created by the machine are lightweight, flexible, and durable, providing excellent cushioning and shock absorption. They can conform to the product’s packaging shape, reducing movement and preventing damage during shipping.

Cushioning and Protection for Shipping

The air cushion machine can be manually operated or integrated into an automated packaging system. It offers a cost-effective and efficient solution for packaging operations that must package and protect items during shipping.

Our range includes various specifications of air machines to meet different packaging requirements. We also offer customisation options and printing services to ensure a tailored packaging solution. Use air pillow machines for a dependable shipping solution that prioritises product safety.

- On-Demand Pillows: Provides air pillows on demand for fast, easy packing in semi- or fully automatic modes

- Fast: Tabletop system produces air pillows at speeds over 55 feet per minute

- All Electric: All-electric design does not require compressed air to operate

- Reduce Packaging Costs: Better air retention and improved yield reduce cost per cubic foot

- Dust-Free: Dust-free air pillows reduce product loss and are cleaner to use than EPS peanuts and paper

- Lower Shipping Costs: A variety of pillow sizes allows the optimisation of space within shipping boxes

- Adjustable speeds: Easily changed the output to meet different packing needs

- Versatile: Single system produces inflated cushions of varying lengths

- Reliable: Minimal wear items and maintenance required

Mini Air Pillow Machine

- Dimensions (Lx W x H): 405mm x 220mm x 195mm

- Weight: 2.5kg

- Voltage: 110-240v

- Speed: 8 metres per minute

High-Performance Air Pillow Machine

- Weight: 15 kg

- Dimensions (Lx W x H): 460mm x 340mm x 470mm

- Speed: 15 metres per minute

- Voltage: 110-240v

Industrial Air Cushion Machine

- Weight:9kgs

- Power:240w

- Speed: 25m/min(82 feet)

- Voltage:220v/110v, 50HZ-60HZ

- Able to work with overhead hopper, winder or basket

- Speed, air, and temperature adjustable

- No belt, minimal maintenance

- Ideal for large-scale warehouse

- One year warranty

- CE, PSE certified

Mini Air Pillow Machine

- Compact and small

- No spare parts needed

- Speed 8 meters per minute

- In-built sensor. It stops automatically when the air pillow film is empty.

- No belt or preheating required

- Works with air pillows and bubble wraps

- Add on options for arm stand and basket, foot pedal etc

- Speed of up to 15 meters

- An external air compressor can be connected

- No belt needed

- The machine can produce air pillows, air tubes, air bubbles and bubble mailers

- Adjustable air volume, temperature and length

- Easy operation and minimal maintenance

- CE-certified, quality-guaranteed

- Speed up to 25 meters

- No belt needed

- The machine can produce air pillows, air tubes, air bubbles and bubble mailers

- Adjustable air volume, temperature and length

- Easy operation and minimal maintenance

- CE, UL, PSE certified, quality guaranteed

Inflatable Air Pillow Machine Product Brochure: Download