Cold Chain Packaging Solutions and Benefits

The ability to adapt to changes and improvements is important in today’s business context due to the constant shift of requirements from consumers. While new products are constantly being launched, packaging methods also evolve. Though there have been significant advancements in packaging solutions, one thing that will always remain would be to choose the most suitable packaging for consumers.

The advancement of packaging continues to evolve. In today’s society, consumers are more concerned about the product’s safety, thus leading companies to improve product packaging, such as having items packed with seals and locks to ensure the product’s safety. Additionally, consumers are provided with various options and facts through a quick search on the web. Thus, most are aware of the product’s origins, how they are stored and shipped, and their expectations of its quality when they receive it.

Numerous products are also temperature sensitive, meaning that specific changes in temperature during transit may be detrimental to the goods and cause damage to them. These products may include perishable things like medicine, fruits, vegetables, and other items requiring a specific temperature range while in transit to ensure freshness. Retain the freshness and lifespan of products in transit with cold chain packaging, a structure of packaging and shipping products sustaining a constant temperature from the manufacturing process to the final delivery of the products.

Understanding Cold Chain Packaging

Cold chain packaging plays a crucial role in preserving temperature-sensitive products’ quality, safety, and efficacy during transportation and storage. Whether it’s pharmaceuticals that need to maintain their potency, food products that require freshness, or biotechnological materials that must remain viable, cold chain packaging solutions ensure that these critical goods reach their destinations in the intended condition.

This packaging solution is designed to maintain a controlled temperature environment for temperature-sensitive products throughout their journey within the cold chain. The cold chain encompasses a series of activities, including production, storage, transportation, and distribution, where maintaining specific temperature conditions is crucial to preserving the quality, safety, and efficacy of various products. Cold chain packaging is essential in pharmaceuticals, food, biotechnology, and chemicals, where temperature control is critical.

Benefits of Cold Chain Packaging

One significant benefit of using cold chain packaging is that it decreases losses and preserves product quality. Due to the product being temperature sensitive, even a minor temperature difference may reduce the quality or effectiveness of the product. It may even be considered completely dangerous to consume or use. Nonetheless, perishables such as make-up may only need to be preserved at a specific temperature range to ensure the freshness of the product during transit.

Hence, various levels of cold chain protection are obtainable and able to meet the specific requirements of each product. This allows manufacturers to modify their shipping containers to the level of care required by the product. It can swiftly balance cold chain thermal packaging costs by constantly decreasing product losses and increasing consumer satisfaction.

Selecting the Right Cold Chain Packaging Solution

Selecting the appropriate cold chain packaging solution is critical for industries transporting and storing temperature-sensitive products. The choice can significantly impact product quality, safety, and cost-effectiveness. When evaluating cold chain packaging solutions, several key factors should be taken into account:

- Product Sensitivity: The nature of the temperature-sensitive product is paramount. Consider its specific temperature requirements, tolerance to temperature fluctuations, and susceptibility to damage from freezing or overheating.

- Transportation Duration: Determine how long the product needs to remain within the desired temperature range. Some solutions are better suited for short-haul transportation, while others excel in long-distance shipments.

- Temperature Range: Identify the required temperature range for your product. Some products require deep freezing, while others need to be maintained at refrigerated or ambient temperatures.

- Regulatory Compliance: Ensure that the chosen packaging solution complies with industry regulations and standards, especially in highly regulated sectors like pharmaceuticals and food.

- Cost: Evaluate the cost-effectiveness of the packaging solution, considering not only the initial investment but also factors such as operational costs, shelf life extension, and potential savings from reduced product loss.

- Environmental Impact: Consider the environmental footprint of the packaging materials. Eco-friendly and sustainable options are becoming increasingly important for ethical and regulatory reasons.

- Packaging Size and Weight: Packaging size and weight can impact transportation costs and logistics. Choose packaging that optimizes space and minimizes excess weight when possible.

- Packaging Integrity: Assess the durability and integrity of the packaging to withstand the rigours of transportation, handling, and potential environmental stressors.

- Customization: Determine whether the packaging solution can be customized to meet the unique requirements of your products and supply chain.

- Temperature Monitoring: Evaluate the availability of temperature monitoring and data logging capabilities within the packaging to ensure real-time tracking and quality control

Cold Chain Packaging Solutions

Selecting cold chain solutions for temperature-sensitive items enables temperature control, making shipping and transport risk-free and simple. Appropriate solutions for certain products can help preserve and safeguard product quality while lowering potential losses.

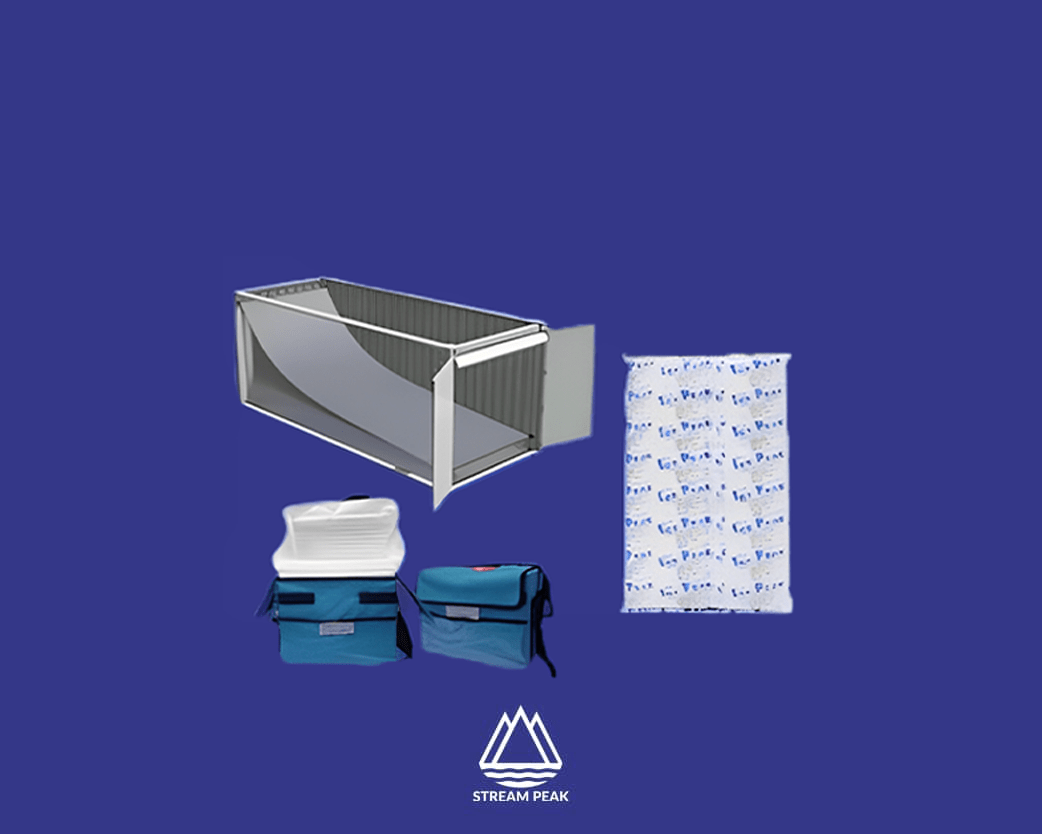

As different levels of cold chain protection suit the various needs of each product, the following are a few packaging solutions: Thermal container liners, Thermal insulators, Ice gel packs, and Condensation terminator sheets when shipping out cold products to preserve and secure temperature.

Thermal Container Liners

Thermal container liners are catered for the interior of shipping containers to prevent freight from damages arising from differences in humidity and temperature during transit. The thermal liner assists by maintaining the temperature and sustaining a 10-20ºC variance between the inner and the container within the freight through insulation.

Moreover, it blocks the formation of condensation within the container, dripping onto the items, possibly leading to mould and corrosion. Finally, it prevents odour and dirt, notably decreasing the costs of cleaning the inner side of the container. Thermal Liner protects not only the container itself but also the contents. Its assembly time is as little as 3 minutes, and it can be used in any standard shipping container. Its cover may be used for various products ranging from perishables such as food and drinks and chemicals to clothing, vehicles, and machinery.

Thermal Insulators

Thermal Insulators consisting of insulated box liners and cooler bags offer a functional, practical, and worthwhile solution for reducing heat transfer between the products and the environment to sustain an ideal temperature.

The insulator creates an effective barrier between the product and the container environment, allowing the product to maintain its optimal temperature for an extended period while avoiding heat or cold loss. This helps preserve the freshness and quality of perishable commodities like food, medications, and other temperature-sensitive items that are cool or frozen while in transportation.

Ice Gel Packs

Refrigerants and ice packs are essential for regulating the temperature inside the packaging. These cooling agents absorb and release thermal energy to maintain the desired temperature range.

Ice packs are typically filled with a gel or liquid that freezes at a low temperature and slowly melts over time, providing a consistent cooling effect. Refrigerants and ice packs are placed within the packaging to ensure products stay within their required temperature range throughout the journey. They are crucial components of cold chain packaging solutions.

Temperature Monitoring Devices

Temperature monitoring devices are critical for ensuring the integrity of temperature-sensitive products. These devices include data loggers, sensors, and real-time monitoring systems.

Data loggers record temperature data at specified intervals, allowing for tracking temperature conditions throughout the transportation and storage process. Sensors provide real-time data; some advanced systems even offer alerts and notifications when temperature deviations occur. These devices are vital in quality control, compliance, and traceability within the cold chain.

Condensation Terminator Sheet

Condensation terminator sheets are absorbent sheets that trap dew-condensation droplets from the container’s ceiling. It is designed to allow water vapour to pass through while barricading water droplets. Following the Sheet’s attachment to the container’s inner side, ensure it is tightly set up and fixed.

When water vapour condenses in the shipping container, it rises, passes through the CT Sheet, and eventually reaches the top of the container. Immediately after the droplets have accumulated at the top, they remain on the CT Sheet, keeping products secured and free from moisture damage while in transit.

Conclusion

Cold chain packaging solutions are not just about preserving products; they’re about ensuring the well-being of consumers, upholding industry standards, and promoting responsible and sustainable practices. By recognizing the benefits and importance of cold chain packaging solutions and working together to promote their adoption, we can continue to raise the bar for product quality, safety, and reliability across various industries.

Stream Peak offers extensive cold-chain packaging solutions tailored to different requirements. We invite you to schedule a consultation with our packaging engineers if you’re interested in safeguarding products from temperature fluctuations. Contact us to explore the best solutions for your requirements.