Corrosion Protection Packaging Strategies

Corrosion can cause damage to products for various industries, leading to significant financial losses and compromised product integrity. Products from electronics and automotive parts to food and pharmaceuticals face the threat of corrosion during storage and transportation.

Fortunately, technological advancements have given rise to packaging solutions, which are crucial in combating corrosion. In this blog, we’ll explore the role of packaging in corrosion protection strategies, highlighting its benefits, applications, and potential to revolutionize product preservation.

Understanding Corrosion

Corrosion is a natural electrochemical process that occurs when certain materials, especially metals and alloys, react with their surrounding environment, leading to their gradual deterioration. It is a complex process involving chemical reactions between the material’s surface and environmental substances, such as oxygen, moisture, acids, or salts. Corrosion can cause visible damage to the material, compromising its structural integrity, appearance, and functionality over time.

The most common form of corrosion is metal corrosion, where metals undergo chemical changes that form oxide or salt layers on their surface. Rusting of iron and steel is a familiar example of metal corrosion. When iron reacts with oxygen and water, it forms iron oxide (rust), which weakens the metal and causes it to crumble.

The Role of Packaging in Corrosion Protection

Corrosion poses a significant threat to various industries and can have devastating consequences if left unchecked. Appropriate packaging to protect against corrosion is not merely a precautionary measure but a vital necessity. Several reasons highlight the need for effective packaging solutions to combat corrosion:

- Preservation of Product Integrity: Corrosion can compromise the structural integrity and functionality of products, reducing performance and even rendering them unusable. Proper packaging acts as a barrier, shielding the products from corrosive elements and ensuring their quality remains intact throughout storage and transportation.

- Cost-Effectiveness: Corrosion-related damages can result in substantial financial losses for businesses. Repairing or replacing corroded components and products can be expensive. By investing in corrosion-resistant packaging, companies can avoid these avoidable expenses and protect their bottom line.

- Extended Product Lifespan: Corrosion can significantly reduce the lifespan of materials and products. Packaging solutions that provide effective corrosion protection can extend the longevity of products, resulting in increased customer satisfaction and reducing the need for frequent replacements.

- Safe Transportation and Storage: Corroded materials and products can pose safety hazards, particularly in industries such as automotive, aerospace, and oil and gas. Adequate packaging prevents corrosion-related failures during transportation and storage, ensuring safer handling and use of the products.

- Compliance with Quality Standards: Many industries are subject to rigorous standards and regulations. Corrosion-related defects can lead to non-compliance with these standards, which may have legal consequences and damage a company’s reputation. By implementing corrosion protection through appropriate packaging, businesses can meet quality requirements and maintain a positive brand image.

- Protection During Export and Shipping: Products often undergo long journeys and face varying environmental conditions during international export and shipping. Corrosion-resistant packaging ensures that products remain well-protected throughout these journeys, reducing the risk of damage caused by exposure to humidity, saltwater, or other corrosive agents.

- Environmental Considerations: Corrosion can release harmful substances into the environment, impacting ecosystems and causing pollution. By preventing corrosion through effective packaging, companies can contribute to sustainable practices and reduce their environmental footprint.

- Enhancing Customer Satisfaction: Customers expect products to be delivered in pristine condition. By utilizing packaging that guards against corrosion, businesses can assure their customers of the product’s quality, reliability, and durability, increasing customer satisfaction and loyalty.

Types of Packaging to Prevent Corrosion

To prevent or mitigate corrosion, various corrosion protection techniques are employed. These techniques include using protective coatings, corrosion-resistant alloys, inhibitors, desiccants, and other packaging solutions to shield materials from the corrosive elements present in their environments.

Additionally, regular maintenance and proper storage conditions are crucial to combating corrosion and extending the longevity of materials and products. Several key strategies can be employed to enhance corrosion protection:

- Barrier Packaging:

Barrier packaging creates a physical barrier between the product and the external environment, preventing corrosive agents from contacting the material’s surface. It is commonly used for metals and electronic components. Examples of barrier packaging materials include moisture-resistant films, foil pouches, and vacuum-sealed packaging.

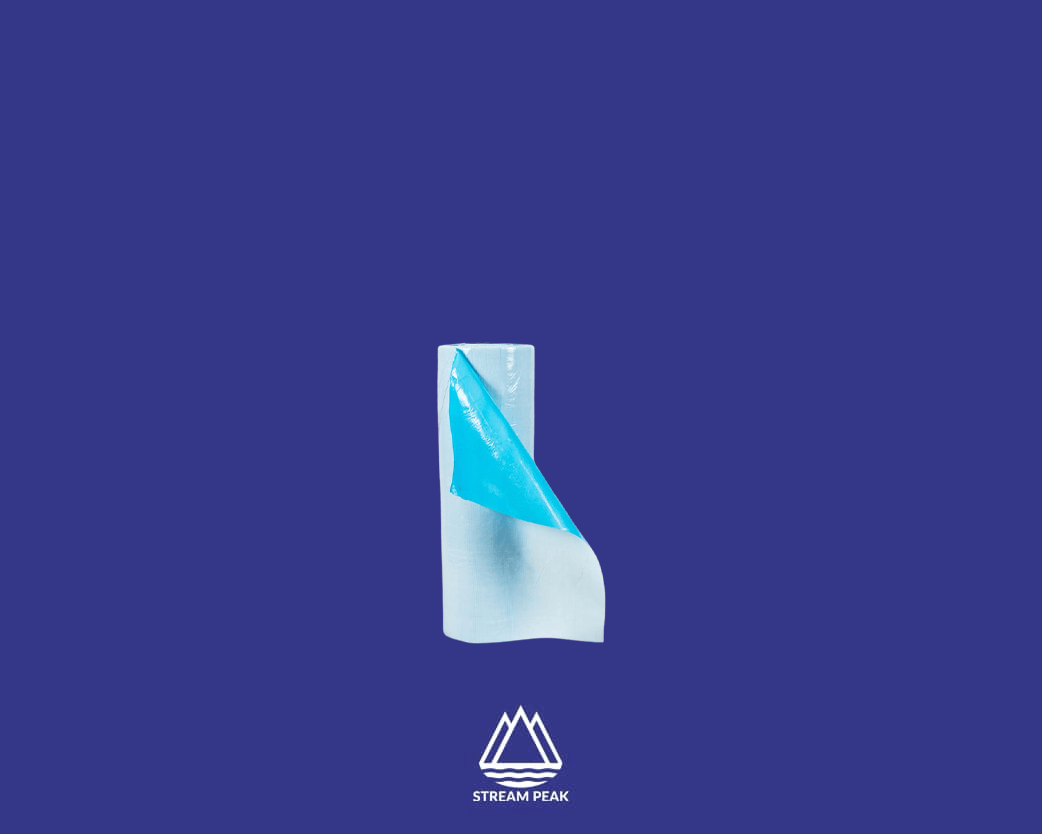

- Corrosion Inhibitor Packaging:

Corrosion inhibitor packaging incorporates substances that release vapour-phase corrosion inhibitors (VCIs) into the surrounding environment. These inhibitors create a protective layer on the metal surface, preventing corrosion by neutralizing corrosive elements like moisture and oxygen. Corrosion inhibitor packaging is particularly useful for metals and components that cannot be in direct contact with the inhibitor. VCIs can be embedded in packaging papers, films, or capsules within the package.

- Desiccant Packaging:

Desiccant packaging involves using moisture-absorbing materials, such as silica gel or molecular sieves, to control humidity levels inside the package. By reducing moisture, desiccant packaging helps prevent corrosion caused by damp conditions, making it suitable for sensitive electronic devices, pharmaceuticals, and food products. Desiccant packets are commonly placed in packaging to absorb moisture during storage or transit.

- Vapour Proof Packaging:

Vapour-proof packaging is impermeable to moisture, oxygen, and other corrosive gases. It is particularly effective for protecting products in marine and offshore industries or those exposed to harsh environments. Vapour-proof packaging materials can include heavy-duty laminates, aluminium foils, and specialized coatings.

- Rust Preventive Oils:

Rust preventive oils are coatings or additives applied to metal surfaces to protect them from corrosion. They are commonly used with other packaging solutions to enhance protection. Rust preventive oils form a thin protective layer that inhibits the interaction of the metal with moisture and oxygen.

- Protective Coatings:

Protective coatings are applied directly to the surface of metals to shield them from corrosive elements. Coatings such as paints, varnishes, and epoxy resins act as a barrier, preventing moisture and oxygen from reaching the metal surface. These coatings are often used in the automotive, construction, and marine industries.

- Climate-Controlled Packaging:

Climate-controlled packaging offers a comprehensive solution for industries with stringent corrosion prevention requirements. These packaging solutions incorporate sophisticated monitoring and regulation systems to maintain specific temperature, humidity, and gas composition levels. Climate-controlled packaging is commonly used in aerospace, defence, and high-tech electronics industries.

- Corrosion-Resistant Alloys and Plastics:

In some cases, using corrosion-resistant materials for packaging can be an effective solution. Corrosion-resistant alloys and plastics, such as stainless steel or certain polymers, are less prone to corrosion and can provide inherent protection to the packaged contents.

Applications of Corrosion-Resistant Packaging

Corrosion-resistant packaging finds widespread applications across various industries where protection against corrosion is critical. Here are some applications of corrosion-resistant packaging:

- Electronics: Packaging for electronics should protect sensitive components from moisture and humidity, which can cause irreparable damage.

- Automotive: Corrosion-resistant packaging helps shield automotive parts during storage and shipping, preserving their quality and performance.

- Food and Pharmaceuticals: In these industries, proper packaging safeguards products from moisture, oxygen, and other contaminants, ensuring their freshness and efficacy.

- Oil and Gas: Packaging for oil and gas equipment must offer robust corrosion protection, as these industries often face harsh environments.

Conclusion

Corrosion protection strategies with packaging have provided effective solutions to combat corrosion and preserve product quality. By understanding the complexities of corrosion and implementing appropriate packaging strategies, businesses can fortify their products against the corrosive elements in their environments.

The diverse range of corrosion-resistant packaging options, such as barrier packaging, corrosion inhibitor packaging, desiccant packaging, and climate-controlled packaging, cater to the unique needs of various industries. By investing in these advanced packaging techniques, businesses can reduce financial losses, promote sustainability, and maintain high-quality standards.