Comprehensive Guide On Using Composite Straps

Composite straps, typically made from a combination of high-strength polyester fibres and a polymer coating, offer a unique blend of strength and flexibility that makes them especially suited for securing various types of cargo. Their lightweight nature and resistance to rust and corrosion give them an edge over strapping materials like steel.

What Are Composite Straps?

A composite strap is a strapping material crafted from high-strength polyester fibres and a polymer coating. This unique composition combines the strength and durability of polyester with the protective and versatile nature of polymers. Unlike single-material straps, the composite nature allows for a balanced force distribution, reducing the chances of breakage or snapping.

Their versatility, safety, and durability make them a reliable option for a wide range of cargo-securing needs. Composite straps, due to their polyester core, are incredibly strong. Their tensile strength is comparable to that of some metal straps. Yet, they remain flexible, allowing them to be used on irregularly shaped or delicate items without causing damage.

Being considerably lighter than steel or other metal straps, composite straps reduce the overall weight of the shipment, which can translate to cost savings. The polymer coating offers protection against external elements. Composite straps are also resistant to UV rays, moisture, and rust, ensuring the strap retains its strength and elasticity even in harsh environments.

Unlike steel straps, which can have sharp edges when cut, composite straps are safer to handle, reducing the risk of injuries during application or removal. They also don’t rust or stain the products they’re securing, making them ideal for items sensitive to such issues. Composite straps also have a slight elasticity, which helps maintain tension and adapt to any settling or shifting of the packaged items.

Applications

The versatile nature of composite straps has found its application across diverse industries and various products. Their strength, flexibility, and safety features make them a packaging solution for various cargo-securing challenges.

For companies that handle large shipments, the strength and durability of composite straps ensure that goods are secure during transit, whether by sea, air, or land. In transporting building materials like bricks, tiles, or wooden planks, the flexibility and robustness of composite straps prove invaluable.

Parts such as tires, engines, and other accessories can be securely bundled together using these straps, minimizing movement during shipment. Composite straps provide security for bulk items or components that need to be held together during storage or transit.

Composite straps can keep them in place when transporting large sacks of produce or bundled agricultural products, preventing damage or spillage. For bundling logs or wooden products, these straps are preferred for their strength and resistance to environmental factors. When shipping large appliances or sensitive electronic equipment, the non-corrosive nature of composite straps ensures the products remain untarnished.

Tools and Materials Needed

When using composite straps, having the right tools on hand is crucial to ensure the strapping process is efficient and effective.

- Strapping Tensioner: This device pulls the composite strap tight, ensuring the contents are secured firmly.

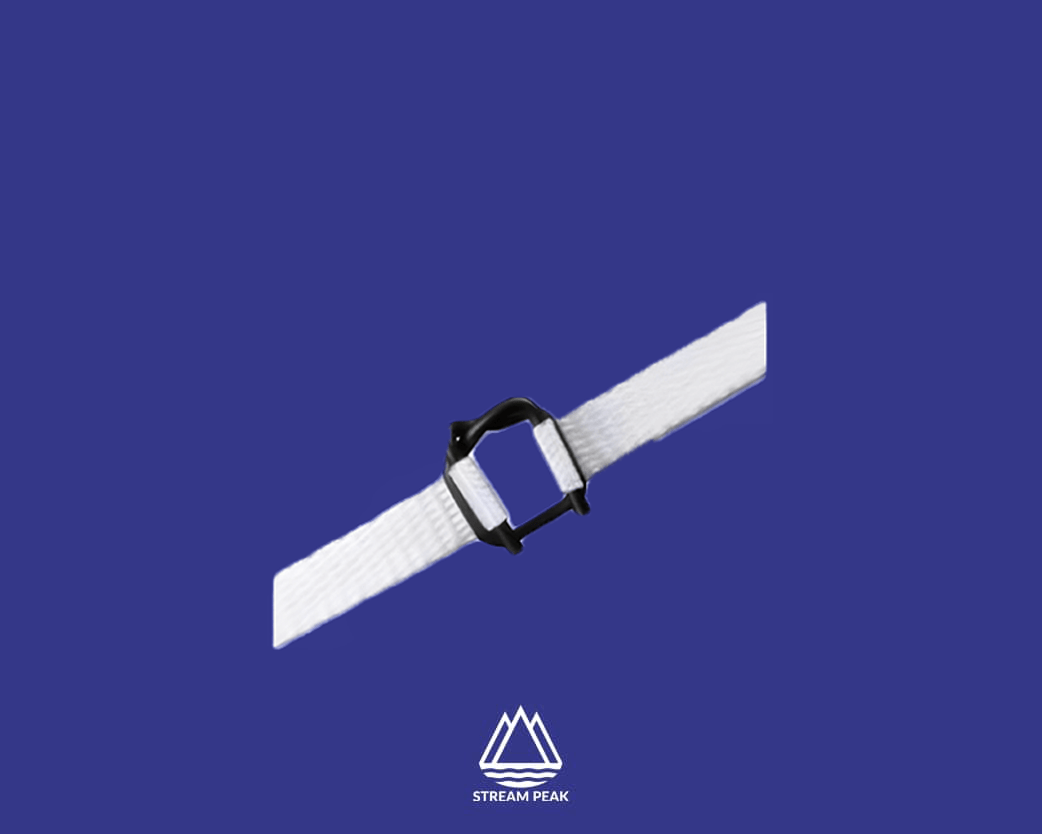

- Sealer or Buckle: A tool or component that helps lock the strap after tensioning. Depending on the type of composite strap used, you might need metal buckles or a specific sealer tool.

- Cutter: A sharp tool, often resembling large scissors or shears, used to cut the strap to the desired length or to remove excess strap after sealing.

- Dispenser: A roll holder or cart that holds the coil of the composite strap, allowing for easy and controlled unwinding during the strapping process.

- Corner Protectors: These are placed on sharp or vulnerable edges of packages to distribute tension and protect the strap and the cargo from damage.

- Strap Guide: A tool to help guide the strap under pallets or around large items, ensuring smooth application.

Safety Gear Recommendations

Equally important is the recommended safety gear, safeguarding the user and ensuring the entire operation runs smoothly and safely.

- Safety Gloves: During tensioning, sealing, and cutting of straps, safety gloves are essential. They shield hands from cuts, abrasions, and other potential injuries, ensuring a safer work process.

- Safety Glasses: Tensioning and cutting straps can lead to snapbacks or the release of small fragments. Safety glasses protect the eyes from such hazards as a barrier against flying debris.

- Safety Footwear: The risk of dropping objects is high in areas where heavy items are strapped. Protective footwear, especially those with reinforced toes, is crucial to safeguard against potential foot injuries.

- Protective Sleeves: When working with longer straps or tight spaces, the arms can be vulnerable to cuts and scratches. Protective sleeves offer an added layer of safety, guarding the arms from such risks.

- Safety Helmet: In industrial or construction areas, overhead risks are a concern. Safety helmets protect against falling objects and potential head injuries, ensuring a safer workspace.

Guide to Using Composite Straps

Ensuring that items are securely strapped ensures the products’ safety and offers peace of mind during transit. Following these steps and paying close attention to each detail can safely and effectively secure items using composite straps. Remember, the key is in the preparation and ensuring that each step is executed with precision and care.

Preparing the Strap: Begin by estimating the length of the strap needed. Wrap it loosely around the item and add a bit extra for overlap and adjustments. Use a cutter or specialized shears to make a clean, straight cut. Before applying, closely inspect the strap for any visible damage, fraying, or imperfections. A compromised strap may not provide the necessary strength during transit.

Placing the Strap Around the Item: Ensure the strap is positioned where it will provide the most support. This often means placing the strap around the item’s centre or across its corners for boxes or pallets. Find a position where the strap won’t slip off for irregular shapes. If using multiple straps, ensure they are evenly spaced and have consistent tension across all straps for balanced support.

Securing with a Buckle or Seal: Depending on the composite strap type, specific buckles or seals might be recommended for optimum hold. Ensure they’re compatible. Thread the strap through the buckle or seal, ensuring enough overlap. If using a sealer tool, clamp down firmly to lock the strap.

Tensioning the Strap: While it’s possible to tension the strap manually, using a tensioner tool ensures a tighter, more consistent fit. Position the tensioner on the strap and pull until the desired tension is achieved. The strap should be tight enough to hold the item securely but not so tight that it causes damage or deforms the package. It’s essential to strike a balance.

Finalizing and Cutting Excess Strap: Any excess strap can be cut off once the strap is tensioned and secured. Use the cutter or shears, ensuring a straight cut for neatness and safety. Always wear safety gloves to protect users from potential cuts. Ensure cutting is done away from oneself and others to prevent any accidents.

Maintenance and Storage

Composite straps, like any industrial equipment, have an optimal lifespan when stored correctly. Store them in a cool, dry place away from direct sunlight. Prolonged exposure to UV rays can weaken the strap’s material over time.

Dispensers or dedicated storage racks can prevent unnecessary tangling or kinking of the straps. This ensures they remain in optimal condition for use. Store straps away from chemicals or solvents, which can degrade the material’s integrity and strength. Ensure straps are off the ground, preferably on shelves or racks. This prevents moisture absorption and possible mould growth.

Inspection and Replacement Guidelines

For safety and efficiency, inspecting composite straps and replacing them when necessary periodically is crucial. Before each use, inspect the straps for wear, fraying, or any visible damage. Even minor damages can significantly reduce the strap’s strength and effectiveness.

If possible, periodically conduct a tensile strength test to ensure the straps retain their original holding power. If a strap shows reduced strength, it’s time to replace it. Keep a record of inspections, noting any observed damages or potential issues. This helps in tracking the lifespan of each strap and predicting when replacements might be needed.

Establish a routine replacement schedule based on the frequency of use and the environment in which the straps operate. Even if a strap doesn’t show visible signs of wear, replacing it after a set period is prudent to ensure safety and efficiency.

Common Mistakes to Avoid

Ensuring the effective use of composite straps is about following the correct procedures and recognizing and avoiding common mistakes.

- Incorrect Tensioning: Over-tensioning can deform the item being strapped while under-tensioning can lead to insecure loads. Use tensioning tools appropriately and familiarize yourself with specific items’ desired tension levels.

- Using Damaged Straps: Avoid using straps with visible signs of wear, fraying, or damage, thinking they retain their strength. Regularly inspect straps before use and replace any that show signs of deterioration.

- Mismatched Buckles or Seals: Avoid using buckles or seals incompatible with the strap’s width or type. Always ensure that buckles or seals match the requirements of the composite straps.

- Inadequate Training: Do not assume that strapping is straightforward without providing proper training to users. Ensure that anyone involved in the strapping process is adequately trained in the technique and safety aspects.

Conclusion

Using composite straps correctly ensures the safety of the items being transported and extends the longevity of the straps. When maintained, stored, and used appropriately, they offer consistent performance, reducing the risks associated with cargo movements.

As with any tool or equipment, understanding its strengths, limitations, and best practices is the key to reaping its full benefits. Investing time in proper training, regular maintenance, and adhering to safety guidelines will maximise the advantages of composite straps, leading to safer and more efficient operations.

Stream Peak offers extensive composite straps tailored to various sizes and specifications to cater to distinct load requirements. Beyond providing quality straps, we are committed to ensuring our clients utilize them effectively. Hence, we offer comprehensive training and consultation on their proper use. Reach out to us for a no-obligation demonstration led by our packaging engineers.