How Does Volatile Corrosion Inhibitors Work?

Corrosion, the gradual degradation of materials due to chemical reactions with their environment, stands as a relentless adversary to industries and infrastructure across the globe. Its economic impact is staggering, costing billions of dollars annually in maintenance, repairs, and replacements.

From the rusting of steel structures and pipelines in the oil and gas sector to the corrosion of automotive components and the degradation of aerospace equipment, the consequences of corrosion are far-reaching. Fortunately, a cost-effective and reliable solution to prevent corrosion is Volatile Corrosion Inhibitors (VCI). This article will closely examine how this rust prevention technology works and why it’s such an effective corrosion inhibitor.

Understanding Corrosion

Corrosion, in its simplest form, can be defined as the gradual degradation or deterioration of materials, especially metals, due to chemical reactions with their surrounding environment. This natural process occurs as metals attempt to return to their more stable, lower-energy state, typically as ores or minerals.

Corrosion occurs when an electrolyte is present on the surface of a metal, and electrons flow from high-energy areas of the metal to low-energy areas in a loop through the electrolyte—the corrosion process results in the formation of oxidation on the metal surface. With the presence of rust inhibitors, electrical current cannot flow from the anode through the electrolyte into the cathode. The corrosion inhibitor molecules attach themselves to a metal surface to form an invisible, thin film that protects the metal from corrosion.

Introducing VCI

Volatile Corrosion Inhibitors (VCI) is a chemical substance that prevents corrosion by forming a thin layer on metal surfaces. The corrosion inhibitor has a high vapour pressure that releases molecules into the air. When the rust inhibitor molecules come in contact with metal surfaces, they adsorb onto the surface and create a protective barrier against corrosive elements such as oxygen, moisture, and chlorides. They are available in various formulations to protect different types of metals, including ferrous, non-ferrous, or multi-metal applications.

How does VCI work?

Volatile Corrosion Inhibitor compounds are instrumental in preventing metal corrosion during storage or transportation. The compounds evaporate from the corrosion inhibitor film and are naturally attracted to the charged surface of the metal. Due to their polar orientation, the anti-corrosion molecules align on the metal surface, forming a layer that passivates the charged surface and acts as a barrier against oxidation. This inhibits the formation of a corrosion cell, which results from the flow of electrons in the metal and ions in the electrolytic surface layer, ultimately preventing corrosion.

VCI can also migrate into recesses and hard-to-reach areas, even on complex shapes. The molecules gradually build up on the metal surface until a continuous barrier is formed, preventing moisture, salt, dirt, oxygen, and other corrosion-causing materials from depositing directly on the metal and causing rust.

The rust inhibitors create a molecular barrier that passivates the charged surface and prevents the formation of a corrosion cell, making it a reliable and cost-effective solution for protecting metal applications. However, this rust prevention technology’s effectiveness depends on several factors, including the types of metals requiring protection, the rust inhibitor chemicals used, and their effects on the metals. In addition, the water solubility of the rust prevention technology and its effectiveness in the presence of moisture and humidity are critical considerations.

Benefits of Volatile Corrosion Inhibitor

Volatile Corrosion Inhibitors offer a range of benefits, including:

- Easy application with no need for messy oils or grease

- No surface preparation is required

- Cost-effective corrosion protection

- Improved safety and pollution control

- Elimination of the need to remove VCI protection, which reduces processing time

- Increased equipment lifespan

Types of Volatile Corrosion Inhibitors

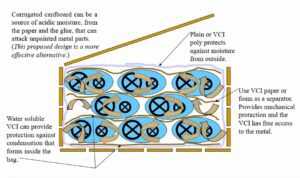

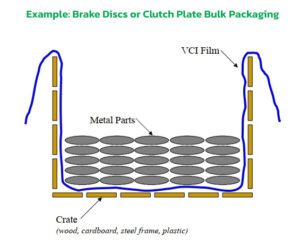

During transportation and storage, metals are susceptible to corrosion due to exposure to corrosive elements such as oxygen, moisture, and chlorides. Corrosion inhibitor paper and films are used to wrap metals to prevent this. When the VCI film comes into contact with metal, anti-corrosion molecules adsorb onto the metal surface, creating an invisible molecular barrier to the eye.

During transportation and storage, metals are susceptible to corrosion due to exposure to corrosive elements such as oxygen, moisture, and chlorides. Corrosion inhibitor paper and films are used to wrap metals to prevent this. When the VCI film comes into contact with metal, anti-corrosion molecules adsorb onto the metal surface, creating an invisible molecular barrier to the eye.

As rust inhibitor molecules evaporate from the film and diffuse throughout the package, they also create a protective molecular layer on metal surfaces that are not directly in contact with the film. When the packaging is removed, the corrosion inhibitor molecules vaporise and dissipate.

In addition to anti-corrosion paper and film, VCI liquids such as transit Coatings, rust removal and lubricating liquids can protect metals. When applied, these liquids adsorb onto the metal surface and create a hydrophobic barrier that prevents moisture from reaching the metal surface, thus preventing the formation of corrosion.

VCI emitters are lightweight disks containing corrosion inhibitors that protect various components inside a box. These slim and compact disks allow accessibility to tight and restricted spaces. Adhesive tape allows corrosion inhibitor emitters to stay firmly on metal surfaces, cabinets, and walls.

VCI bags are coated with compounds that act as barriers between metal and corrosive substances. The unique formula of VCIs seeks out metal surfaces and attaches to them, providing a protective layer that covers the entire surface.

Finally, VCI powder protects the interior of equipment such as tanks, vessels, boilers, and piping, especially for voids and recessed areas of interior cavities during storage or transportation. The powder is typically applied by fogging, blowing it into the interior space, or using packets.

Packaging Design Criteria

Consideration should be given to several criteria when selecting corrosion inhibitor packaging, including:

- Variety of metals in need of protection

- Length of protection required

- Domestic or export

- Climate Conditions

- Size and weight of the product

- Value of the product

Good Example of VCI Packaging

To ensure adequate protection, using one square foot of the rust inhibitor paper/film for every three square feet of surface area or one square foot for every cubic foot of packaging volume is recommended. Any printing on the anti-corrosion paper/film should face away from the metal to maximise its effectiveness.

Conclusion

In conclusion, volatile corrosion inhibitors are an effective and cost-effective solution for preventing corrosion. It works by creating a protective barrier on metal surfaces that prevents the flow of electrical current and the formation of oxidation.

Various formulations of VCI, each suitable for specific applications, offer several benefits, including ease of application and improved safety. By understanding how corrosion inhibitor works and how to use them, companies can protect metal products and extend their equipment life. Learn more about frequently asked questions on VCI and watch a video explaining how this rust prevention technology works.

Stream Peak offers a diverse range of Volatile Corrosion Inhibitors (VCIs) suitable for a wide array of industries and applications. Our VCIs come in various formulations, including films, papers, emitters, and oils, providing long-lasting protection by creating a molecular barrier on metal surfaces. Contact our packaging engineers for a no-obligation appointment.