Key Factors to Consider When Buying a VFFS Machine

Vertical Form Fill Seal (VFFS) machines efficiently form, fill, and seal various products, ranging from food to pharmaceutical products. By understanding these essential aspects comprehensively, narrow down choices and identify the VFFS machine that optimally suits specific production environments, product characteristics, and operational objectives.

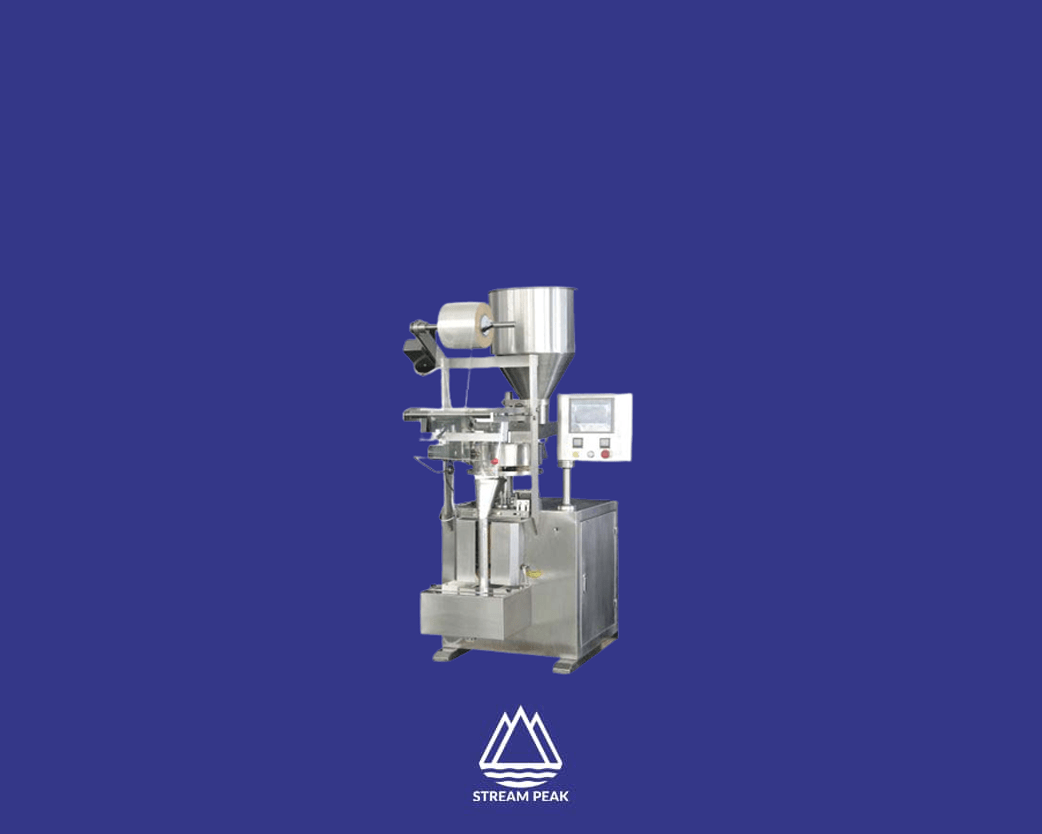

What Are VFFS Machines

VFFS machines are automated packaging systems that integrate several functions, including forming a bag from a roll of packaging film, filling it with the desired product, and sealing it to create a finished package.

These automatic packaging machines are used for dry goods, powders, snacks, liquids, and granular products. VFFS machines offer precise control over packaging, ensuring efficiency, accuracy, and consistency.

Benefits of VFFS Machines

VFFS machines automate packaging, improving efficiency and higher production speeds. They can handle large volumes of products, reducing manual labour and streamlining operations. With their high-speed capabilities, VFFS machines can significantly increase output and meet growing market demands.

Packaging machines offer flexibility in packaging design and formats. They can accommodate various bag styles, such as pillow bags, gusseted bags, and stand-up pouches, allowing brands to choose the most suitable packaging for their products. This versatility enables effective branding and differentiation on store shelves.

An accurate filling is essential to maintain product consistency and meet weight specifications. VFFS machines can have advanced weighing and dosing systems that ensure precise fill volumes, reducing product waste and improving quality control. This accuracy is particularly important in industries where product integrity and compliance are critical, such as pharmaceuticals and food.

VFFS machines provide excellent sealing capabilities, creating airtight packages that help extend the shelf life of products. The hermetic seals protect against moisture, oxygen, and contaminants, preserving product freshness and quality. This especially benefits perishable goods or products with specific shelf life requirements.

By automating the packaging process, VFFS machines reduce the need for manual labour, leading to cost savings in the long run. They also minimise material wastage using precise packaging measurements, reducing production costs.

Factors for Selecting a VFFS Machine

Choosing the right VFFS machine ensures efficient and reliable packaging operations. This section will explore the key factors to consider when selecting a VFFS machine.

1. Packaging Requirements

Before investing in a VFFS machine, evaluate the packaging requirements. Consider factors such as the type and size of products to be packaged, the desired packaging speed, and the required packaging materials. Understanding specific needs narrows the options and helps choose a VFFS machine aligned with production goals.

Every packaging machine has differing characteristics in which it can operate. It includes the maximum bag size a machine can seal, the type of material, and the fill weight the machine can accommodate. Providing these details to the supplier can allow them to select the most suitable machine. For instance, knowing the product enables the machine supplier to recommend a machine together with the material.

2. Machine Versatility

Flexibility is a significant consideration when selecting a VFFS machine. Look for a machine that can handle various product sizes, shapes, and packaging formats. The ability to adapt to different packaging requirements ensures that the investment remains relevant and adaptable as the product line evolves.

3. Packaging Speed

Assess the speed and output capabilities of the VFFS machine to ensure it meets the desired production capacity. Consider factors such as quick changeover times between different products or packaging formats. A high-speed VFFS machine with an easy setup enhances productivity.

4. Equipment Size and Space

Packaging machines come in various sizes and are built to accommodate different spaces within facilities. Some are made for less floor space but occupy more vertical space. Measure the available space in the production facility and ensure the selected machine seamlessly fits into the workflow. Consider the dimensions, including height, width, and length, and any additional space required for the equipment.

5. Quality and Reliability

Investing in a reliable and durable VFFS machine is crucial for long-term productivity. Research the reputation and track record of the packaging manufacturer to ensure the machines are built to high standards. Read customer reviews and testimonials to gauge equipment reliability and the level of customer support provided.

6. Operator Training and Support

A VFFS machine’s performance requires well-trained operators and engineers. Look for a packaging manufacturer that provides comprehensive training programs and ongoing technical support. Well-trained operators maximise the machine’s capabilities, reduce downtime, and ensure smooth operations.

7. Maintenance and Serviceability

Consider the ease of maintenance and availability of spare parts when evaluating VFFS machines. Opt for a machine that allows easy access to critical components and offers quick and hassle-free maintenance procedures. Additionally, inquire about technical support and after-sales service availability to minimise potential disruptions to the production line.

8. Cost and Return on Investment (ROI)

While cost is a significant factor, it should not be the sole determinant when purchasing a VFFS machine. Focus on the overall value and long-term ROI rather than the upfront price. Evaluate the machine’s lifespan, maintenance costs, energy efficiency, and potential for future upgrades. Choosing a machine with optimal performance and reliability over its lifespan is a wise investment.

Conclusion

Selecting the right VFFS machine can help efficient and reliable packaging operations. By considering factors such as packaging requirements, machine versatility, speed and efficiency, equipment size, quality and reliability, operator training and support, maintenance and serviceability, and the overall cost and ROI, an informed decision that aligns with business objectives can be made. Investing time in research and due diligence will pay off in the long run, ensuring a VFFS machine that meets the criteria for successful packaging operations.